Torque motor |Brochure| Version 2.3

Torque motors for ultimate speed and precision

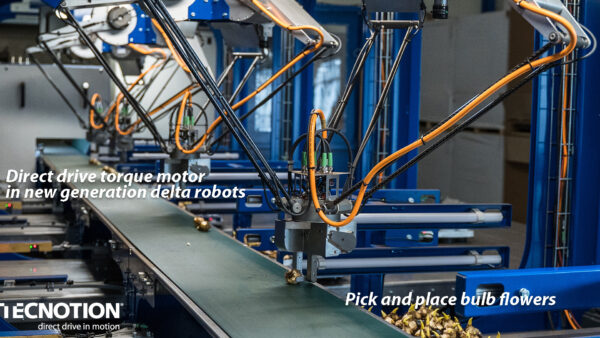

The new generation delta robots have one thing in common. Their design replaces the familiar servo motors with gearbox, opting for direct drive torque motors instead. Together with Tecnotion, Brom mechatronics designed and build the first delta robot production line to place flower bulbs into pots. The build-in frameless torque motors play an important role to increase productivity and reduce costs.

From the initial drawing up to production, Brom mechatronics and Tecnotion have co-operated to select the best fit motor. Four torque motors from Tecnotion are used in the three arms and in the tool center point of each delta robot . A direct drive motor is much more compact than a motor & gearbox. This property allows the motor to be built directly in the moving arms and tool center, with the small QTR integrated in the toolcenter to rotate the product, the delta robot can be kept more compact.

Download the leaflet and check out how our torque motors can be used in delta robots and how direct drive motors can improve ultimate speed and precision in delta robot application.