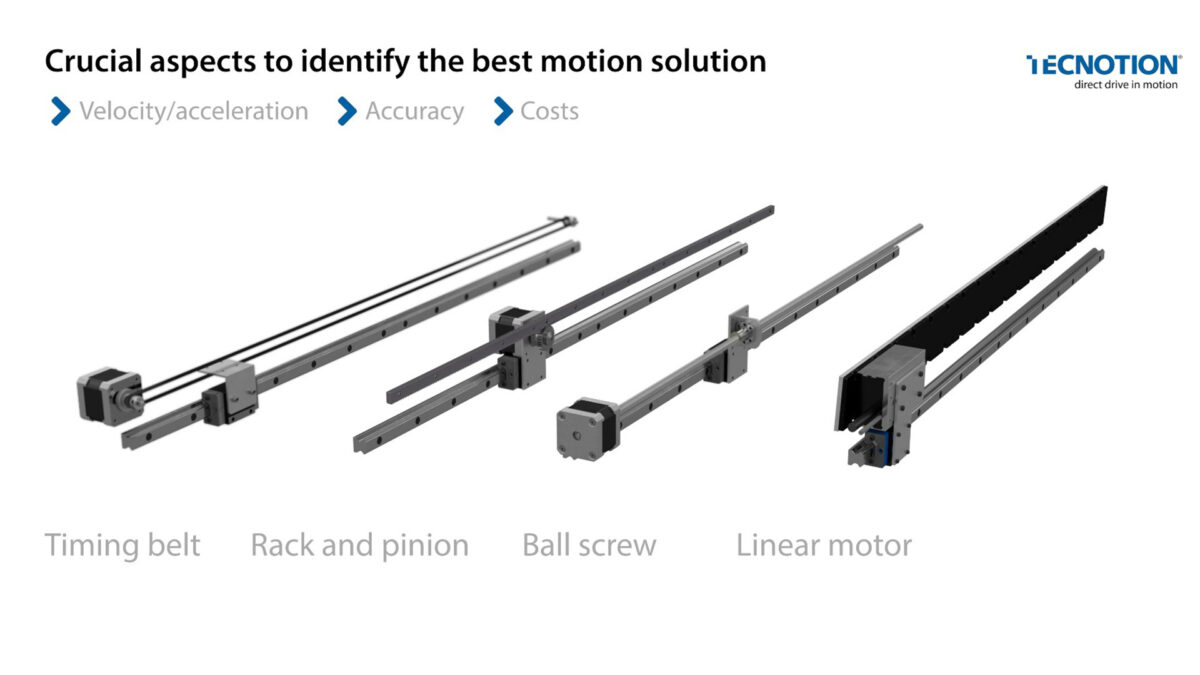

Linear motors are also referred to as direct drive units since the load is directly coupled to the motor. This eliminates the need for elastic components such as gearboxes and couplings, which introduce backlash and error in the motion. And because they do not rely on mechanical drive components such as ball screws, belts, and rack and pinions, linear motors have much higher accuracy and repeatability, with no velocity ripple.

This lack of rotating or recirculating parts also makes them virtually maintenance-free and contributes to a lower total cost of ownership when compared to traditional drive mechanisms.

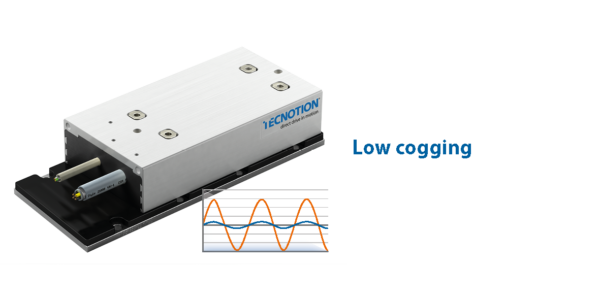

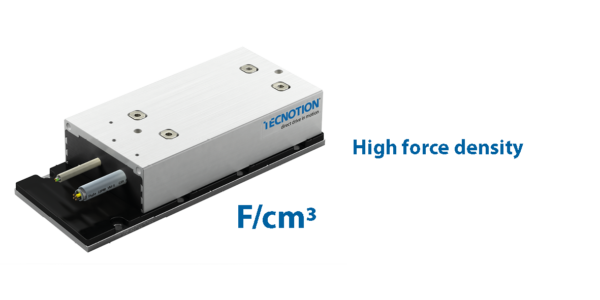

ADVANTAGES OF IRON CORE MOTORS:

- High force density and more force in a smaller packing mean lowering footprint and fitting better in small spaces.

- Low cogging, optimized iron core motor design, for smooth motion and position accuracy in your application.

- Approved for CSA and CE, ROHS, Iron core motors are approved for CE, CSA, and ROHS.

- Aluminum housed design with integrated water cooling for TBW- and TL series

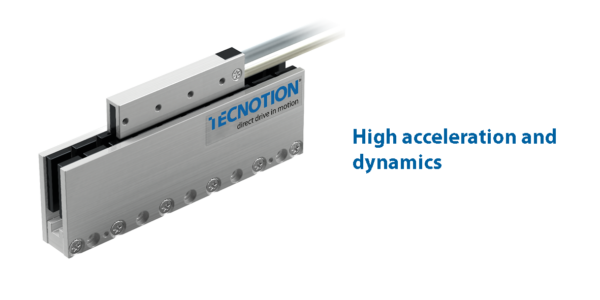

ADVANTAGES OF IRONLESS MOTORS:

- With high acceleration and dynamics, the outstanding force-to-mass ratio of the ironless coils enables unmatched system dynamics.

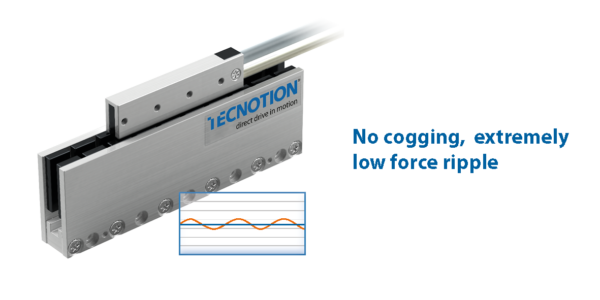

- No cogging, extremely low force ripple, Ironless motors have no cogging effects. Offering smooth motion and position accuracy in your application.

- Approved for CE and ROHS, Ironless motors are CE and RoHS approved.

- Low thermal resistance, allowing good heat transfer, achieving an extremely high continuous force for all motors when using a decent size heatsink or active cooling.

For more info and specifications, please check our Ironless and Iron core product pages.

Ask us directly

Mike Rolink and Stefan Jansen

Application Engineers

“Do you have a question about a motor? Or do you need technical support during an installation? Call us and one of our Application Engineers will help and support you throughout the entire process.”

Ask your question