Torque motors

Increased dynamic performance of your application

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

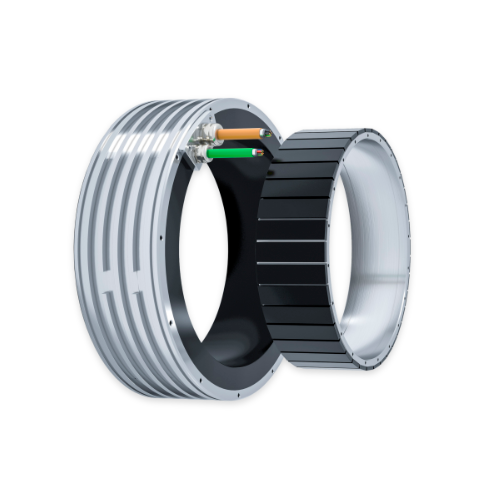

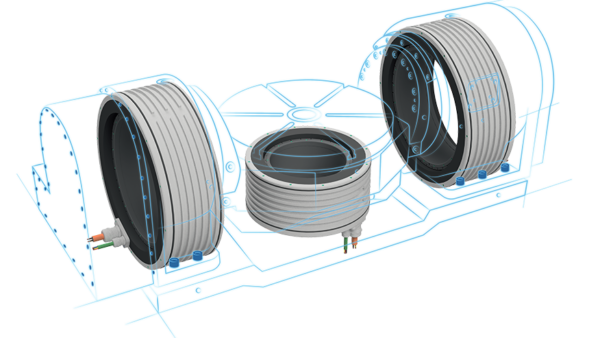

High stall torque with direct drive motors. Depending on the application, machine tooling can make different demands on the qualities of an actuator. High speeds are required for the spindle, high accuracy and/ or repeatability are key for tool positioning, and a high stall torque is required for the workpiece. These qualities can all be achieved with Tecnotion direct drive motors, such as the QTL torque motor, or large iron core linear motors.

Torque and linear motors provide high-precision and repeatable motion in the sub-micron range, mainly as a result of the very stiff coupling of the rotor and the axis of direct drive motor technology. The low electrical time constant ensures a quick reaction response and low settling times, thus improving the time to manufacture the workpiece.

The electromagnetic design of the Tecnotion torque stators results in a low-cogging motor experience. The magnetic design of the torque motors as a whole, combined with an anti-cogging algorithm ensures that the motor has almost no speed ripple. These qualities are essential in the machine tooling industry where low accuracy leads to low-quality workpieces.

High torque is an important parameter for machine tooling when a workpiece needs to be held into place or when high accelerations are required. Tecnotion torque motors offer very high torque density enabling high performance in a relatively small package, which makes them ideal for machine tools. The QTL torque series can be provided with an aluminum housing with cooling channels. Adding this water cooling even further increases the maximum performance of the motor. In addition, the metal housing makes installation easier due to the added bolt holes. All motors are supplied as a kit, with the rotor already placed in the stator, making installation fast and easy.

High speeds are required when using e.g. cutting tools. To maximize the speed of the motor, Tecnotions smaller QTR series offers a variety of torque motors with several winding types. These winding types are especially useful for driving demanding cutting tools.

The harsh environment in a machine tooling application can be destructive for certain materials of the motor. Coolant can destroy PVC cables. Tecnotions QTL series comes standard with a polyurethane (PUR) cable, which can withstand this destruction.

Torque motor |Brochure| Version 2.3

Torque motor |Webinar| Version 1.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.