Torque motors

Increased dynamic performance of your application

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

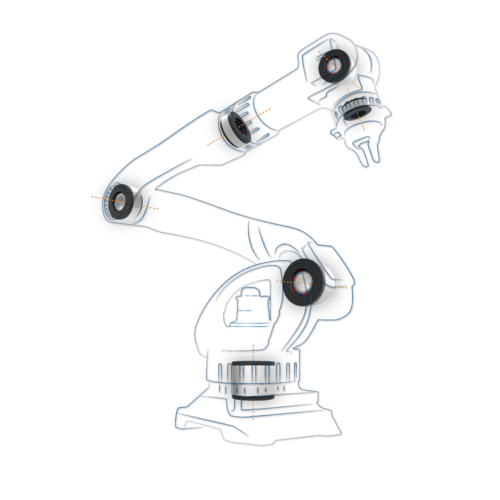

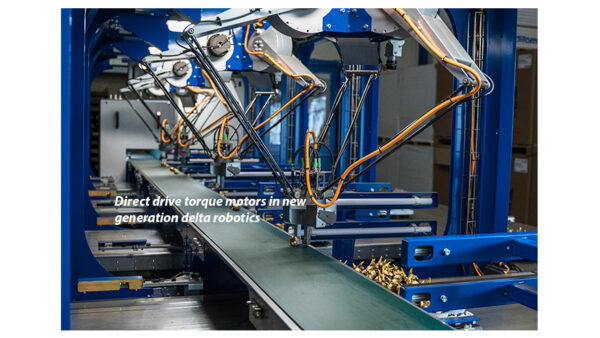

Improve dynamics and force density and eliminate the gearbox in your Robot application, with direct drive motors. Within a wide variety of industries, robotic manipulators can improve productivity, accuracy, and reliability. Direct drive motors are ideal to advance the robot performance.

With a traditional delta robot, a gearbox is used to increase the torque of the servo motor to drive the arms of the robot. The higher torque of a direct drive torque motor enables a delta robot without a gearbox. Eliminating the gearbox lowers the complexity of the robot and reduces maintenance over the robot’s lifetime.

A torque motor is also ideal to replace the rotation axis. The low mass of the torque motor allows placement in the moving head of the robot making a driveshaft from the base to rotate the tool center point.

Torque motors have a large diameter due to the hollow shaft. This makes it possible to run the z-axis rod of a SCARA robot, with the torque motor providing the rotation movement for the z-axis rod. The direct coupling of the motor with the z-axis rod enables high inertia payloads with faster acceleration in comparison to belt drive motors and conventional servo motors.

The large inner diameter of torque motors also allows SCARA designs using concentric shafts, driving different arm segments. This way, the arm itself can be kept compact, with all the motors located in the base: below and away from any sensitive payload, e.g. wafer handlers.

Tecnotion torque motors can be used to provide a rotary motion or indexing motion in an End-of-arm-tool [EOAT]. The high torque-per-weight ratio of torque motors helps to keep the weight of the tool low and in turn, keep the load on the robot arm low.

Linear motors provide a direct drive solution for linear axis in a Cartesian robot system. By eliminating the rotary to linear transmission components, required when using rotary servo motors, the performance of the robot system improves significant. It results in lower inertia, reduced wear & tear and lower compliance between motor and load.

The track of a linear motion system is modular and can be built to any desired length. Linear motors also offer the option to use multiple coil-units on one track, allowing multiple, independently moving payloads on only one track.

The new generation of delta robots has one thing in common. Their design replaces the familiar servo motors with a gearbox for direct drive torque motors. Together with Tecnotion, Brom mechatronics designed and build the first delta robot production line to place bulb flowers into pots. The build-in frameless torque motors play an important role to increase productivity and reduce costs.

Torque motor |Brochure| Version 2.3

All linear motors |Brochure| Version 3.0

Iron core motor |Webinar| Version 1.0

Torque motor |Webinar| Version 1.0

Torque motor |White paper| Version 1.1

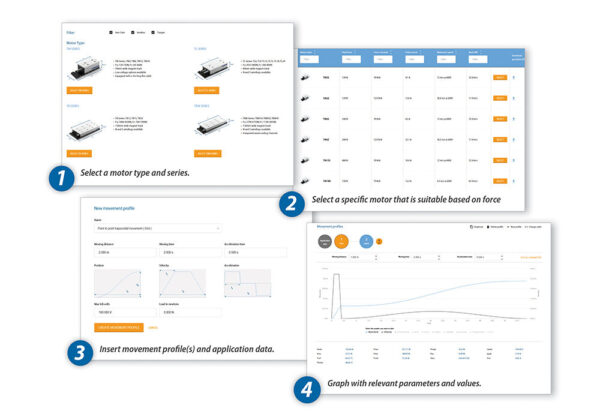

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.