Custom motors

Adapt our standard motor series to meet your needs

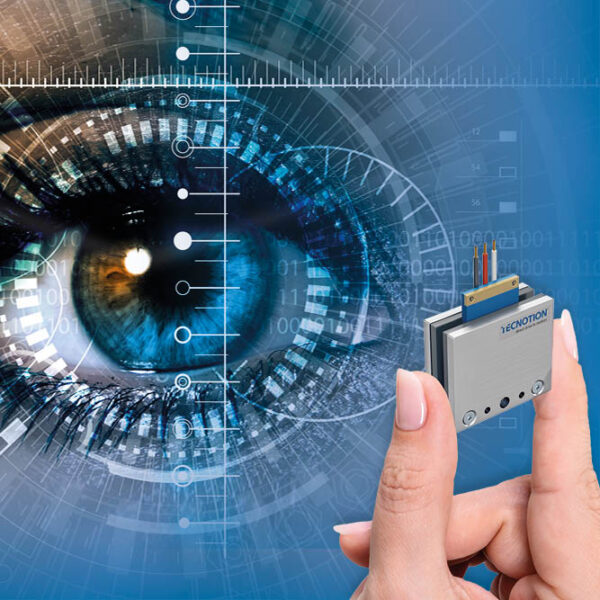

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

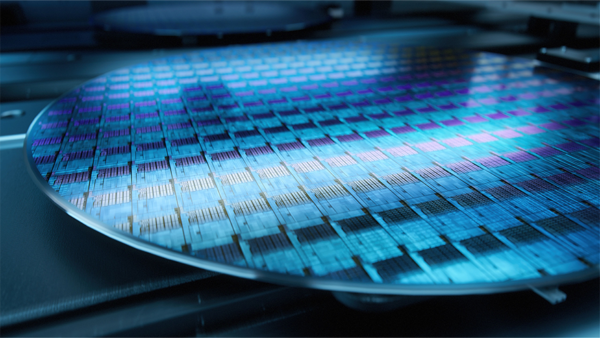

High precision in semiconductor industry applications. The main parameter that characterizes motion in the semiconductor industry is high precision, be it front- or back-end. Regardless of the application; lithography, metrology and inspection, wafer handling, and die-attach, all require the stage to have high accuracy and repeatability with ever-growing throughput requirements, resulting in an optimized cost per unit and best system ROI. Direct drive motors make these requirements possible.

Whether atmospheric or vacuum environment, Tecnotion linear and rotary motors can meet these needs.

With the increasing number of electronical products in today’s society, the need for microchips is growing rapidly. This results in more fabs around the world, all using the high-tech equipment needed to produce a microchip. Tecnotion direct drive technology can be found in the complete range of semiconductor applications from front-end, at the wafer level, through inspection to back-end pick & place and measurement technology.

Imaging the most accurate structures on a wafer requires many motors to align and control all moving parts in the complex machine. To ensure accuracy on nanometer level, Tecnotion creates custom solutions together with their customers to meet these extreme requirements.

Designed for when every millimeter matters, but high-performance cannot be compromised.

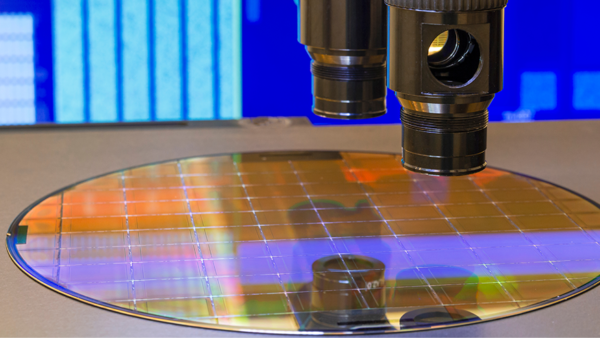

When the wafer is processed, many control steps take place. This is often performed with an ironless linear motor driven application, to ensure critical dimensions. Ironless linear motors ensure metrology and inspection systems are accurate and precise with a dynamic task.

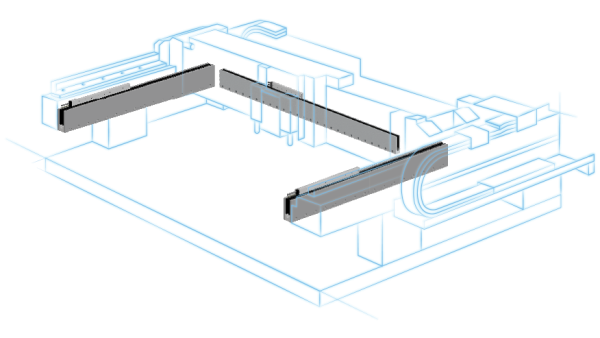

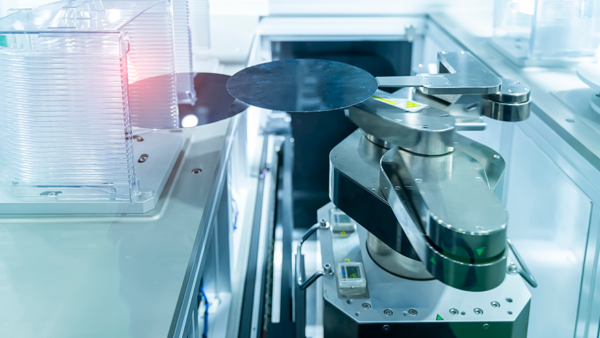

Multiple Direct drive motors are used for wafer handling inside semiconductor equipment. Torque motors are applied in wafer-handling scara robots, were the motors ensure that the wafer is accurately rotated or transported safely to the process chamber or the next station. Linear motors are also used for translational movement inside semiconductor equipment. Tecnotion offers products for both cluster and in-line challenges.

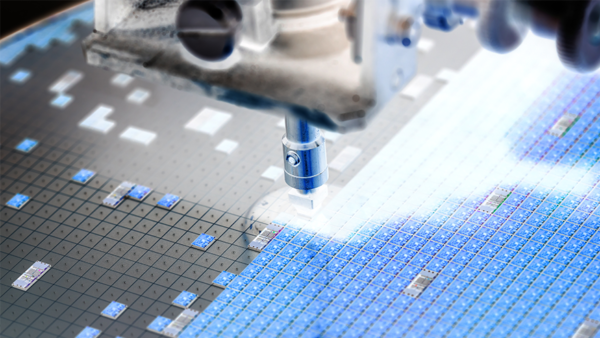

After the processing steps the wafer undergoes a number of steps before becoming a chip. These steps are known as back-end manufacturing steps. First, the wafer is sliced into individual chips, a process commonly referred to as wafer dicing. Then also wire bonding and die attach take place, in which the dies are connected to the substrate and many electronical connections are being formed.

To keep the throughput as high as possible, these pick and place movements need to occur at very high speed and with sub-micron accuracy. Tecnotion ironless motors are perfectly suitable for these applications because of their low mass and high accuracy.

Many applications in the semi-conductor industry take place in a vacuum environment, for example in electronics, or in the 3C market (computer, communication & consumer electronics). In such an environment, a standard motor will not work as, it will not be able to withstand the low air pressure and the outgassing will be unacceptable.

To enable movement in vacuum, Tecnotion has a complete range of ironless vacuum motors. These motors are designed to deliver the desired force and precision while having very low outgassing in order to keep your environment clean.

Vacuum applications tend to be more complicated than non-vacuum applications. Contact our team of application engineers to support you in choosing the right motor and inform you about the curiosities to expect in a vacuum environment.

Vacuum motor |Brochure| 1.4

Ironless motor |Brochure| 1.3

Torque motor |Brochure| Version 2.3

All linear motors |Brochure| Version 3.0

Iron core motor |Webinar| Version 1.0

Torque motor |Webinar| Version 1.0

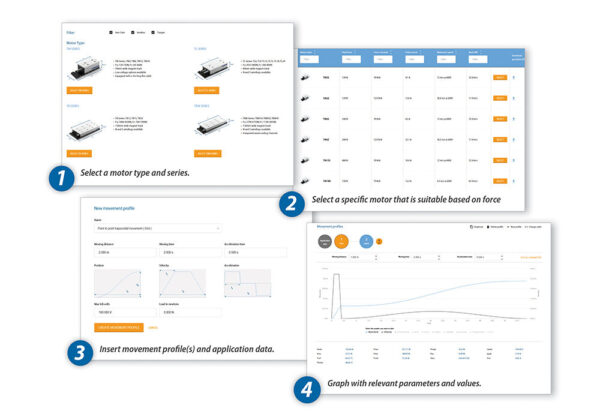

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.