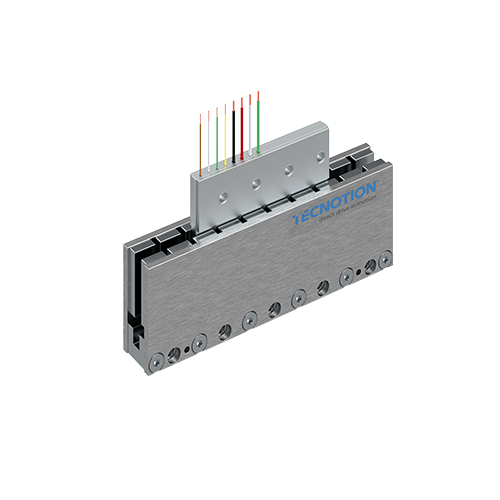

Vacuum G2 motors

For powerful and precise processes

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

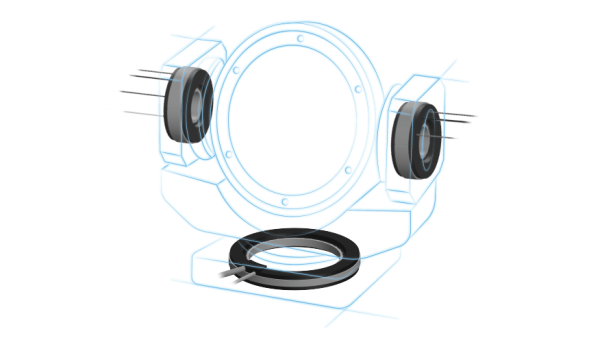

In both science and aerospace there are many applications where camera’s, radars and antenna’s need to be pointed accurately onto their point of interest. Here, the drive motoring the movement has a direct impact on the speed at which a subject can be tracked or found.

Due to their form factor and high torque, direct drive torque motors can be coupled directly to the load. This eliminates any lost motion – e.g. backlash- and compliance in the transmission from motor to load with a conventional setup. The resulting direct connection allows tighter control of velocity and position.

In addition, Tecnotion torque motors are designed with low cogging and torque ripple in mind. This reduces any disturbance onto the requested position, minimizing velocity ripple or tracking error.

Another advantage of mounting the motor directly to the load is the size reduction. By eliminating coupling and transmission, a very compact solution can be created. In addition, the QTR and QTL series offer a large rotor inner diameter, which allows for cables to run through the rotor, keeping them within the structure of the gimbal or radar – well protected against all environmental influences.

Torque motor |Brochure| Version 2.3

Torque motor |Webinar| Version 1.0

Iron core motor |Webinar| Version 1.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.