Iron core motor |Brochure| 1.2

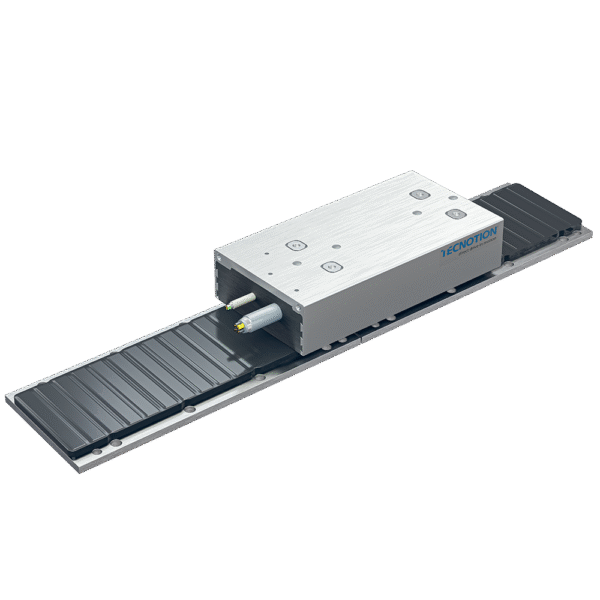

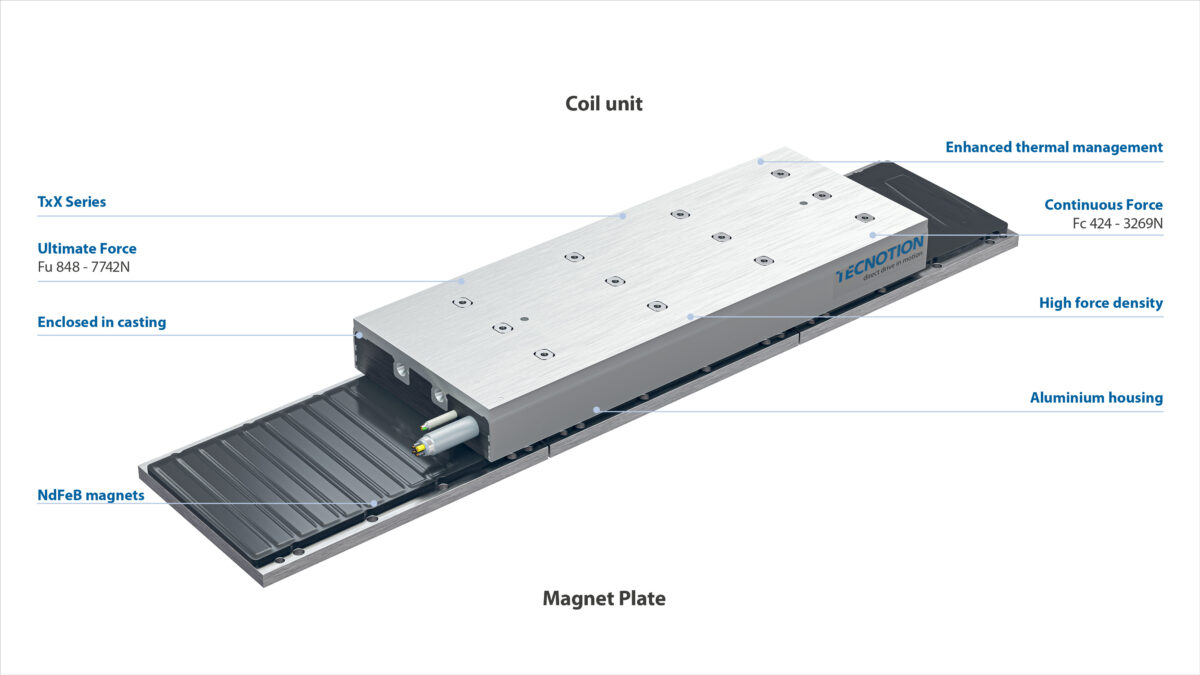

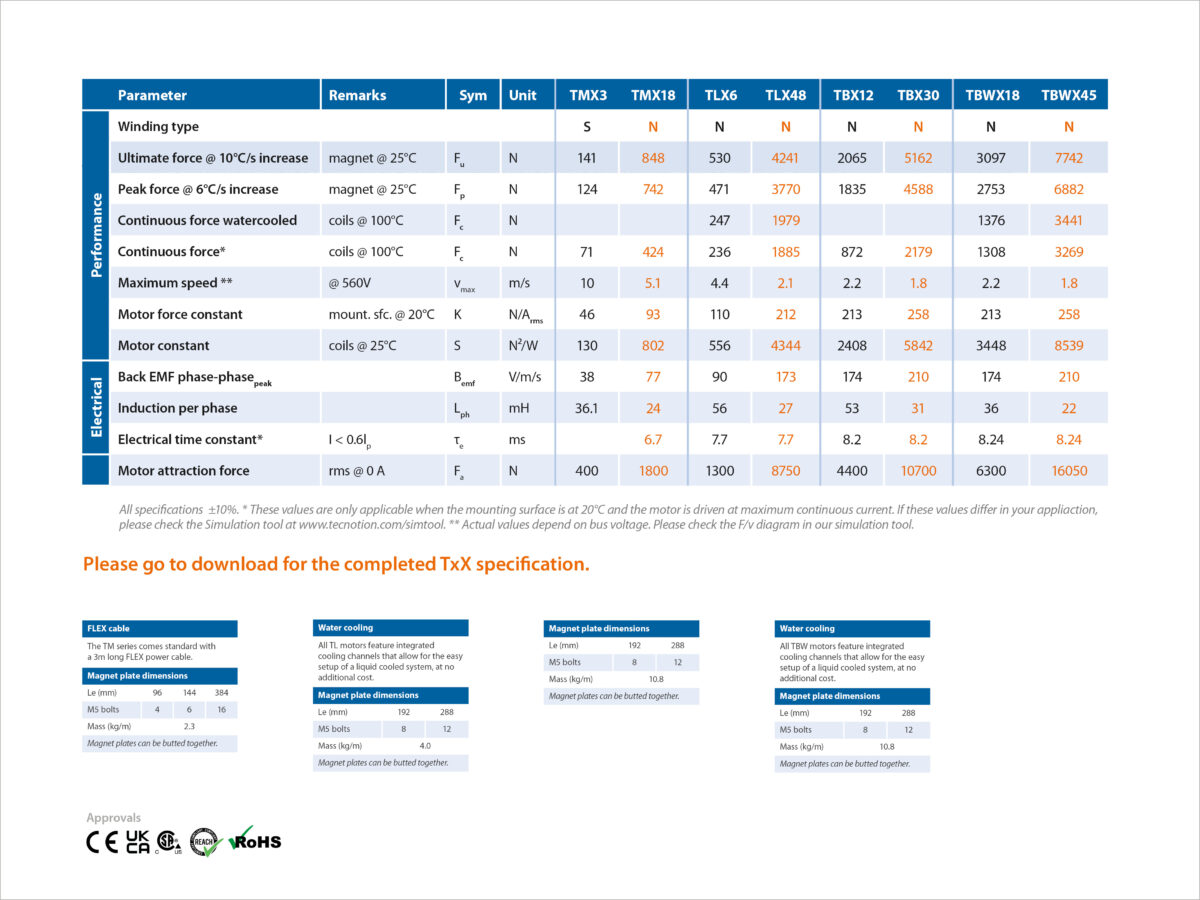

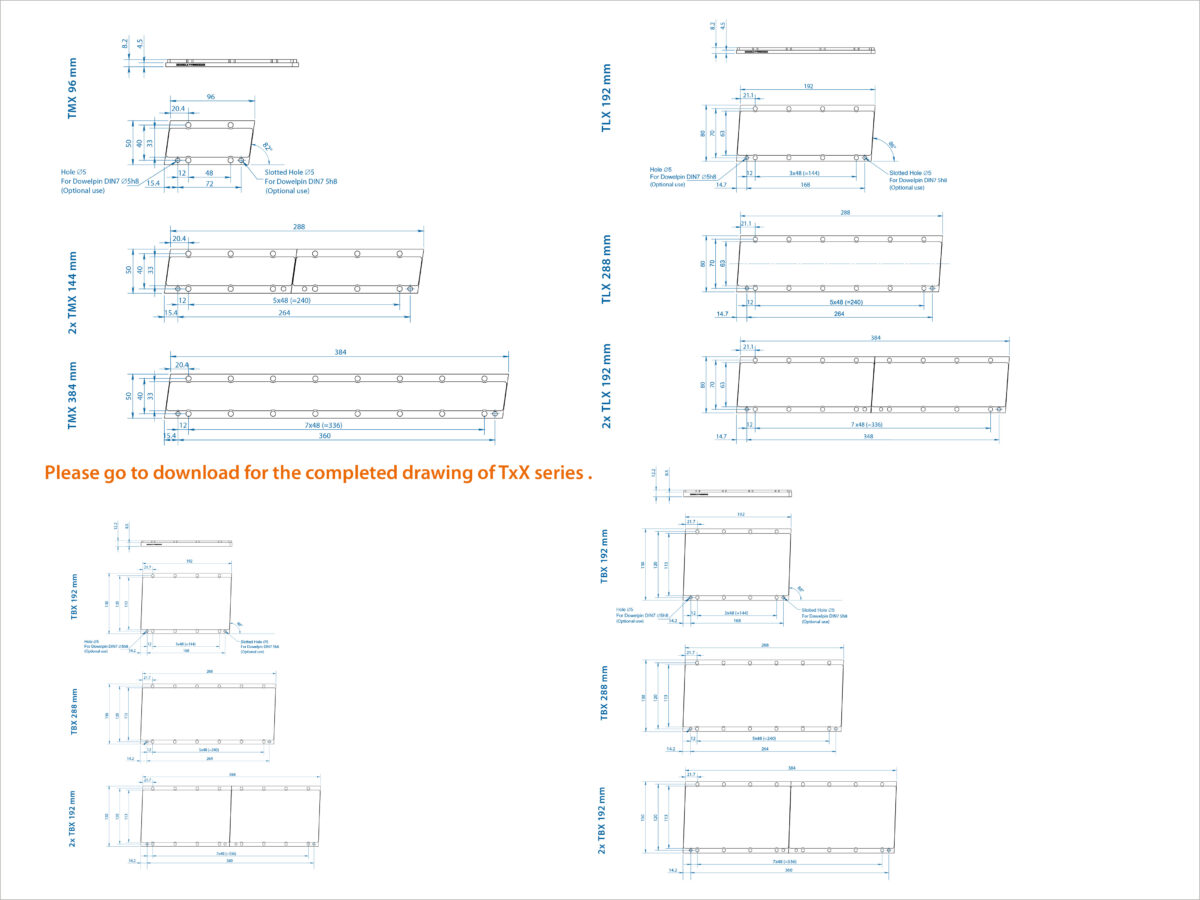

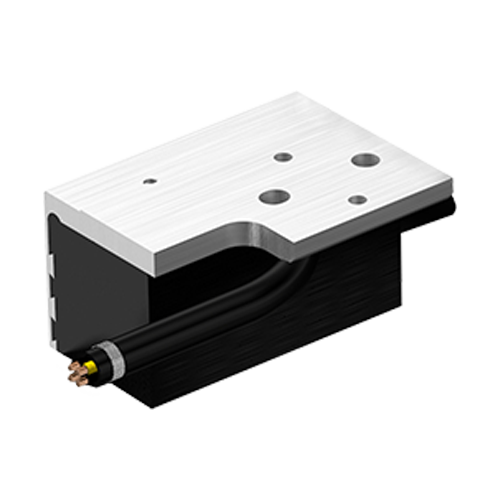

TxX series

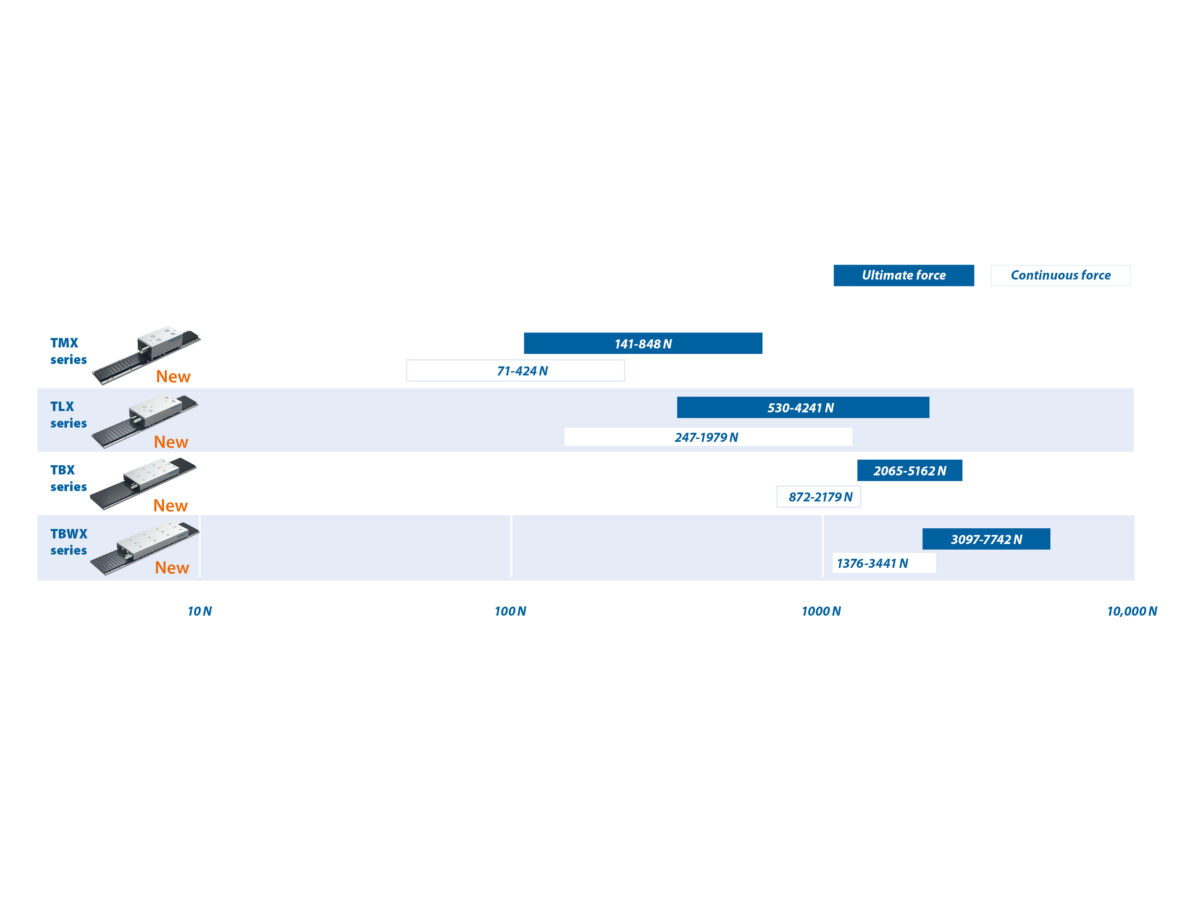

Higher acceleration and improved efficiency

Designed with an optimized force constant, these motors boost efficiency, enabling your system to handle heavier loads and achieve higher accelerations with ease.

Minimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Designed with an optimized force constant, these motors boost efficiency, enabling your system to handle heavier loads and achieve higher accelerations with ease.

The TxX Series features stronger magnet plates, allowing for a compact motor design that takes up less space in your system.

The new TxX iron core linear motors have an optimized force constant, making your system more efficient and capable of handling heavier loads or higher accelerations. The use of stronger magnet plates in the TxX series can allow for smaller motor size design reducing the space required in your system.

Iron core motor |Brochure| 1.2

Iron core motor |Leaflet| version 1.0

All linear motors |Spec sheet| version 1.0

All linear motors |Spec sheet| version 1.0

All linear motors |Spec sheet| version 1.0

All linear motors |Spec sheet| version 1.0

Iron core motor |Manual| version 2.1

Iron core motor |CAD file| version 2.0

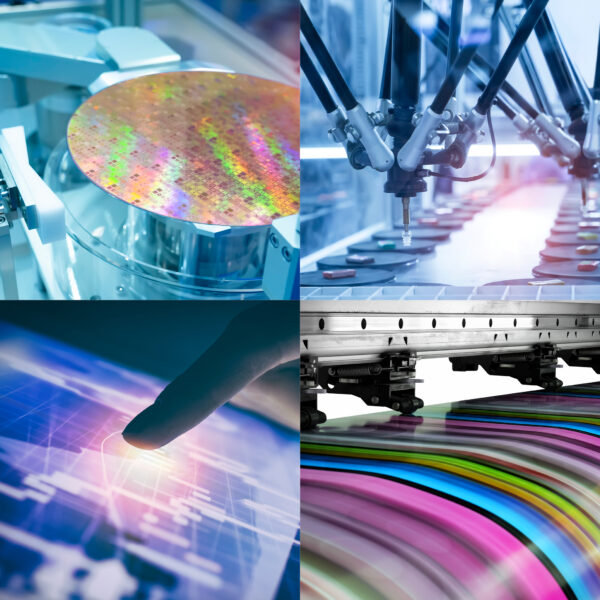

Tecnotion direct drive motors are seamlessly integrated into a wide variety of applications, such as semi-conductors, machine tooling, robotics, display applications and printing industry. We direct drive your motion technology.

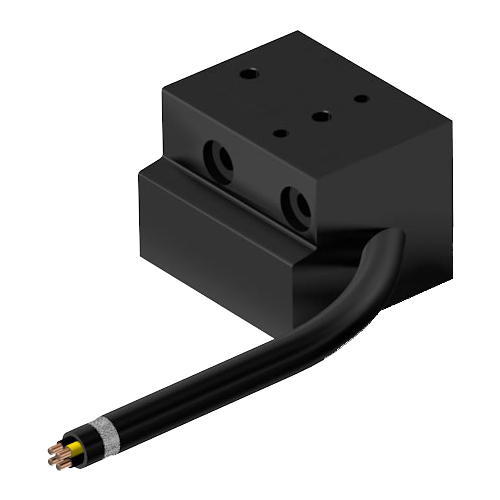

For commutation, Tecnotion has an optional Digital Hall Module that can be used with our entire range of linear motors. Its sensors provide 3 digital outputs, each phase shifted 120 degrees, to determine the electrical angle between coils and magnets. If you do not use a controller that allows you to commutate within the servo drive, this module can be a cost-effective alternative. The digital Hall module requires a 4.5 to 28Vdc power supply.

Linear motors can be positioned extremely accurately by using optical encoders and rulers. If this is not required this expensive setup can be replaced by an Analog Hall module. This module uses the magnet track, as opposed to the ruler, as the linear scale. It can be easily mounted on our iron core motors and communicates with practically all standard servo controllers. The Analog Hall module requires a standard 5Vdc power supply.

Find the best linear motor according to your application criteria. Select a product type and choose relevant values to filter the most suitable motor.

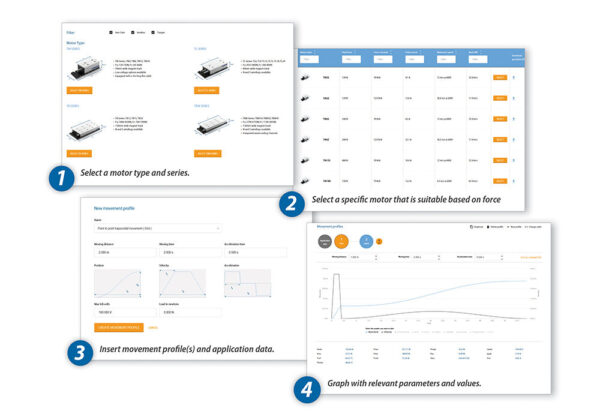

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.

Mike Rolink and Stefan Jansen

Application Engineers

“Do you have a question about a motor? Or do you need technical support during an installation? Call us and one of our Application Engineers will help and support you throughout the entire process.”

Ask your question