Torque motor |Manual| version 2.2

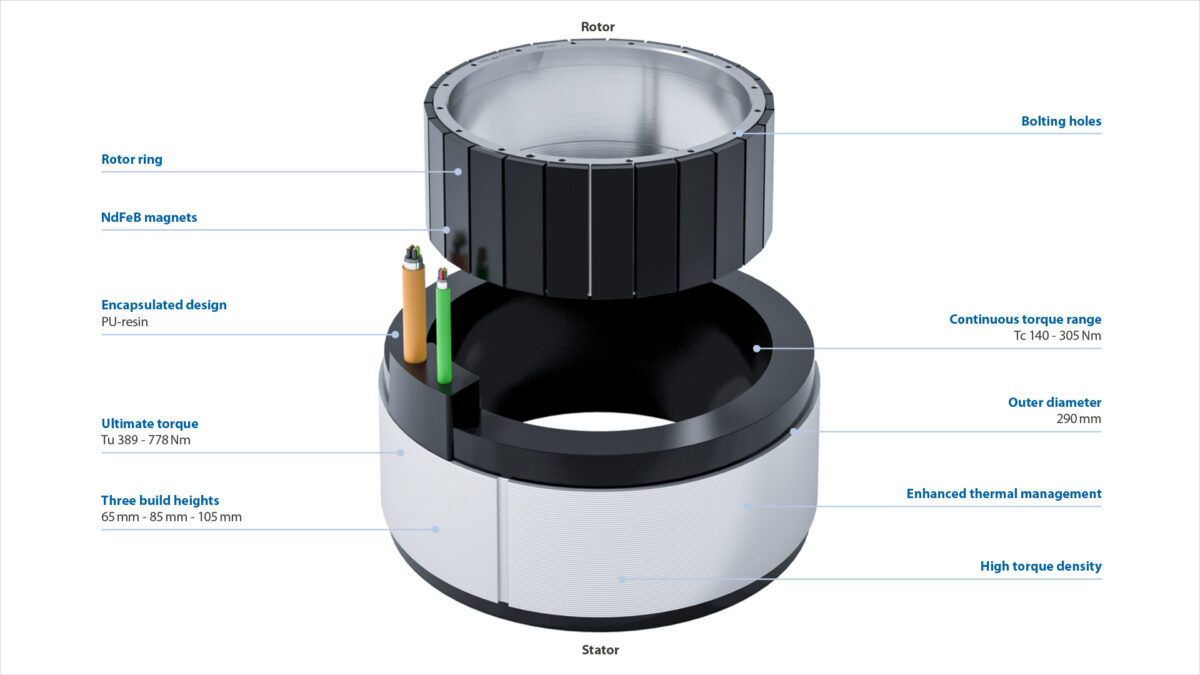

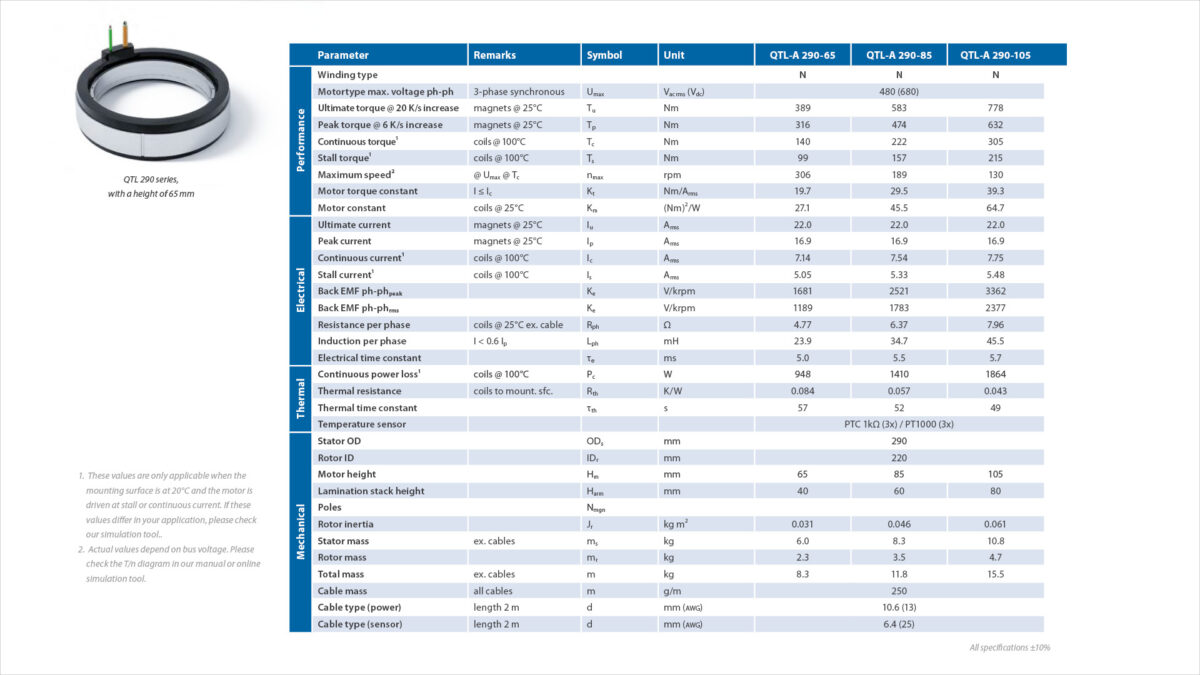

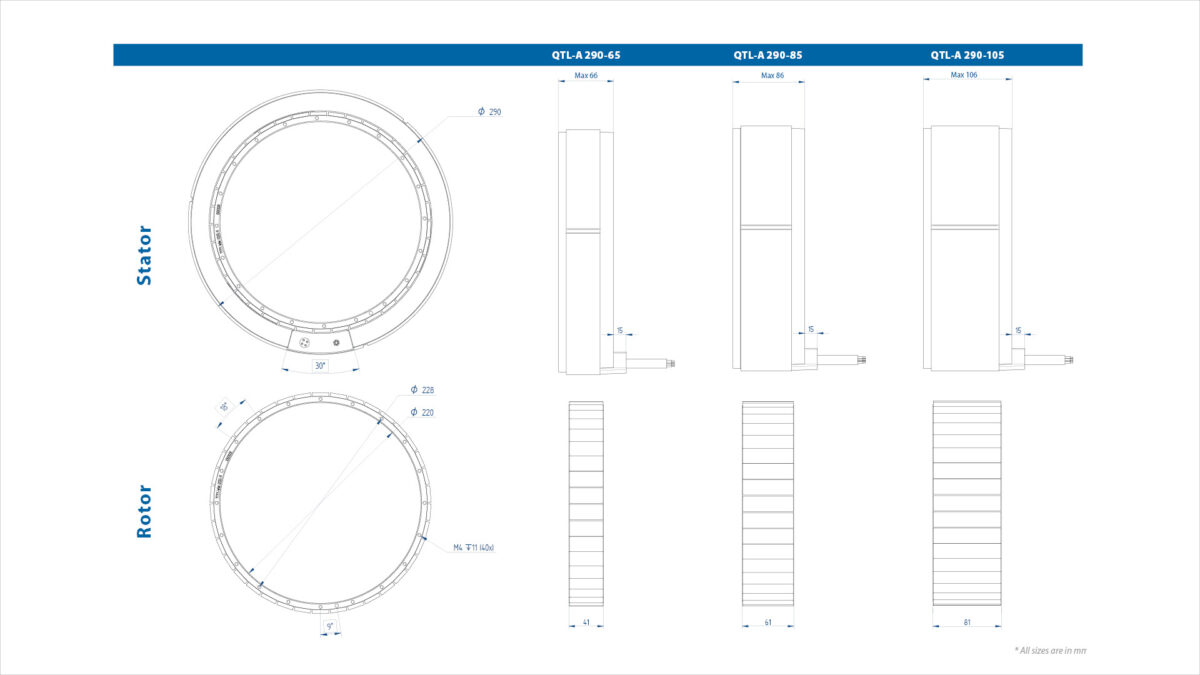

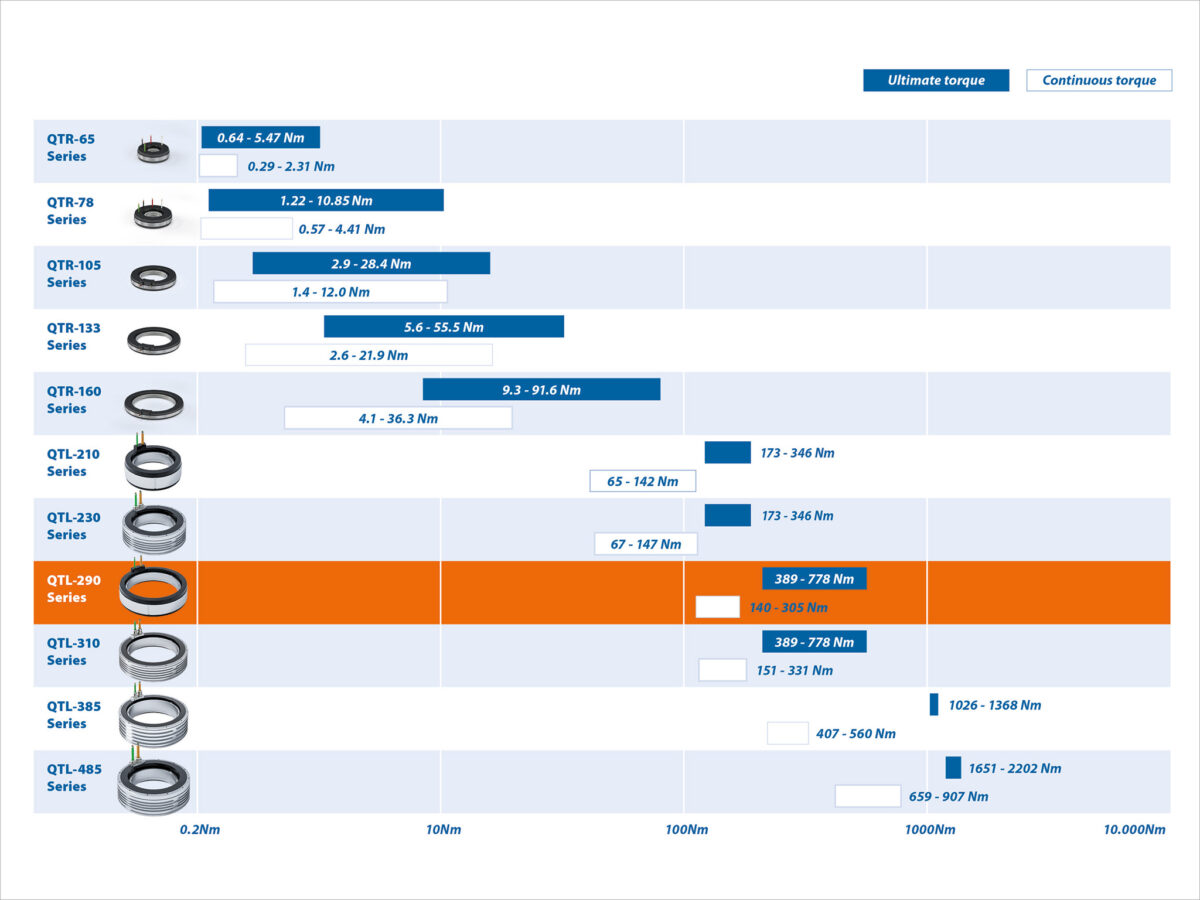

Torque QTL 290 series

Ready for highly dynamic movements in machine applications.

Low induction values and fast response times allow for highly dynamic movements, making the QTL 290 series ideal for usage in packaging and laser cutting machinery.