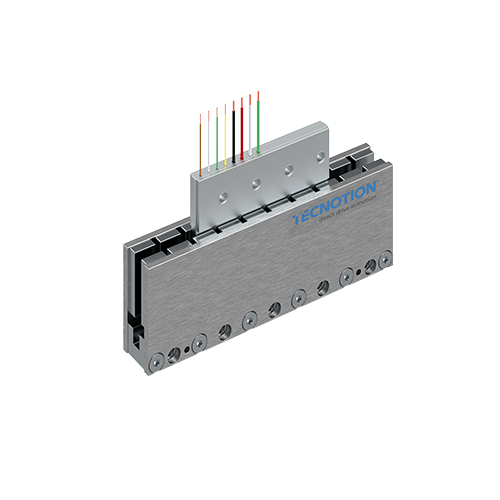

Vacuum G2 motors

For powerful and precise processes

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Linear motors in display manufacturing. The manufacturing of displays requires a machine that can move high masses, regularly in a vacuum environment to prevent contamination of the display. This requires one or multiple motors with a high force output, especially when the vacuum limits the performance.

The amount of time that we spend looking at an electronic screen is significant. Televisions, smartphones, and computer screens all have one thing in common, the screen is typically a flat-panel display. The manufacturing of these flat-panel displays is challenging due to the high moving mass and the patterning steps of the display take place inside a vacuum.

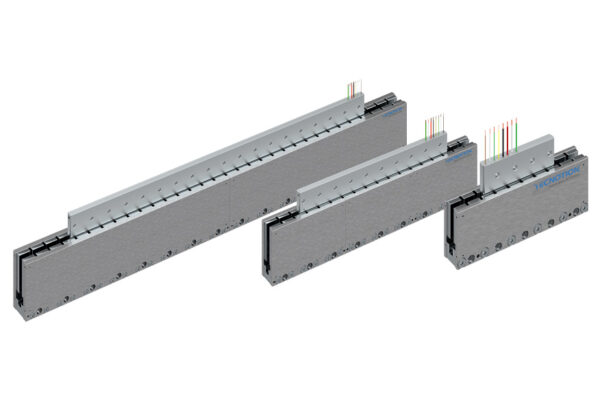

The displays undergo many treatments, such as lithography, etching, drilling, cleaning, inspecting and repair. Depending on the application requirements, ironless or iron core linear motors are used for positioning. Some of the treatment steps take place in a vacuum environment. For these steps, vacuum linear motors are most suitable. To achieve the required force and move high masses, multiple linear motors can be coupled.

Because of the unique design of Tecnotion vacuum linear motors and the manufacturing inside the cleanroom, the vacuum motors have minimal outgassing and optimal cleanliness. All vacuum motors meet the properties that are essential for display manufacturing. The combination of vacuum motors with a high-quality vacuum-rated encoder ensures that accuracies in the sub-micrometer range can be achieved.

For some applications it is useful to use iron core vacuum magnet plates in combination with a standard iron core motor to perform better movement. In this case, the motor is placed outside the vacuum and the magnet plates inside the vacuum. The airgap between the two will be bigger than normal, resulting in some force loss. However, the iron core motor outside the vacuum can still generate more force than the ironless vacuum motor. Also, the iron core motor has better cooling possibilities outside the vacuum environment.

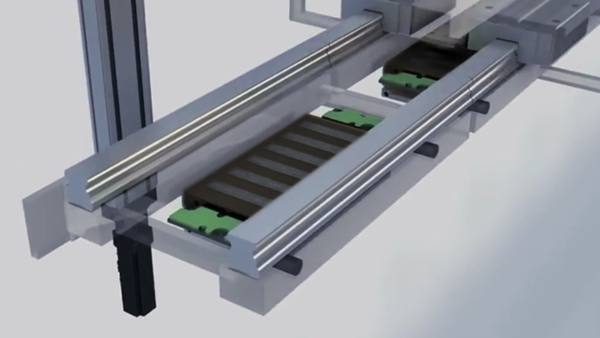

For many deposition, evaporation and sputter processes like CVD, PVD and ALD, also used in display manufacturing, transport or motion is needed inside the vacuum. These production lines consist out of different process chambers where deposition processes take place. This requires in-vacuum transport systems, which can be created by linear motors in a moving magnet configuration.

Within Tecnotion we have experts which can consult on your application beyond motor level, as integration of such systems need to be matched closely on requirements. Besides motion requirements environmental and thermal condition must be taken into account where the envelope for motor parts is restricted by the vacuum chambers physical limitations.

Vacuum motor |Brochure| 1.4

All linear motors |Brochure| Version 3.0

Iron core motor |Webinar| Version 1.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.