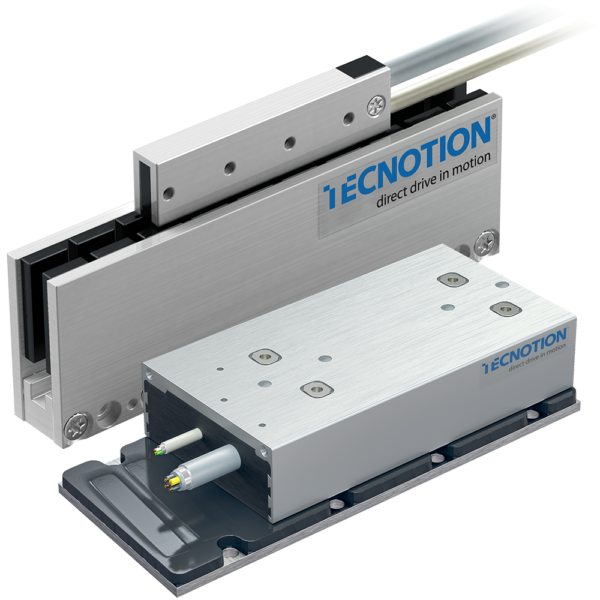

Linear motors

Unmatched acceleration and dynamic movements

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

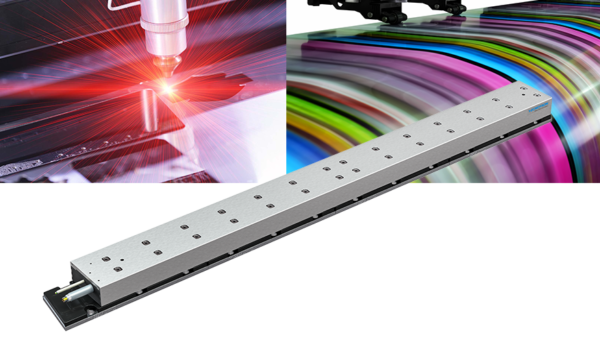

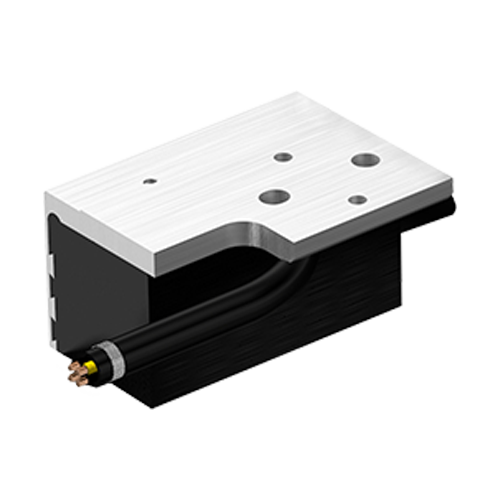

Digital cutting machines require fast setup times between tasks, increased variety in design, and the ability to manage a wide variety of materials. The characteristics of a digital cutting machine can be further enhanced by completing a cutting job faster, with better-cut quality, and smoother operation by using linear motors.

Increased throughput

Increased throughputFaster traversing speeds and rapid short length cuts and curves lead to shorter cutting times and increased machine throughput. Tecnotion Iron core motors offer high force density for best-in-class acceleration and top speed.

Download the leaflet Iron core Linear motors in digital cutting applications

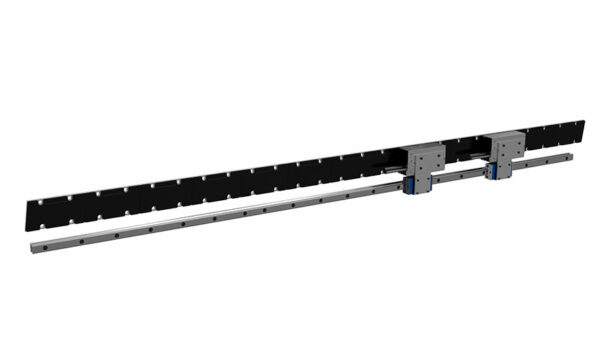

It is easy to run multiple heads in a linear motor as the individual coil units move on a single magnet track. Coil units can move independently of each other which is ideal for multiple cutting heads (or beams) on one machine.

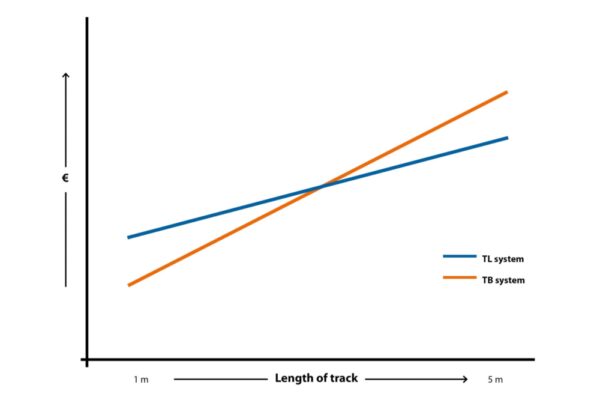

For large machines requiring long track lengths, our extra-long coil units provide high force on a cost-effective (thinner) track, making them best suited for these applications.

Adjusting the working area of a machine is easy to do by adjusting the length of the magnet track. Multiple magnet plate lengths are available, which can be combined to create any required track length.

Linear motors operate contactless and virtually wear-free. The lower-than-average attraction force reduces the impact on bearing lifetime and lowers the required stiffness of the machine frame. The motor components require no maintenance or adjustment during their lifetime. This is ideal for digital cutting applications.

Linear motion is delivered by the motor itself, eliminating the conversion from rotary motion to linear motion, as seen with belt drives and rack & pinion solutions. The elimination of coupling and transmission components allows for more accurate control of the cutting tool.

The above advantages of direct drive motors for linear motion axes can also be extended to any rotary axis. Our wide range of torque motors are designed to provide rotary motion without any transmission components. They offer faster rotation and quicker settling times to further reduce cutting time.

Linear motors can be positioned extremely accurately by using optical encoders and rulers. If this is not required this expensive setup can be replaced by an Analog Hall module. This module uses the magnet track, as opposed to the ruler, as the linear scale. It can be easily mounted on our iron core motors and communicates with practically all standard servo controllers. The Analog Hall module requires a standard 5Vdc power supply.

Torque motor |Brochure| Version 2.3

All linear motors |Leaflet| version 2.0

All linear motors |Leaflet| version 2.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.