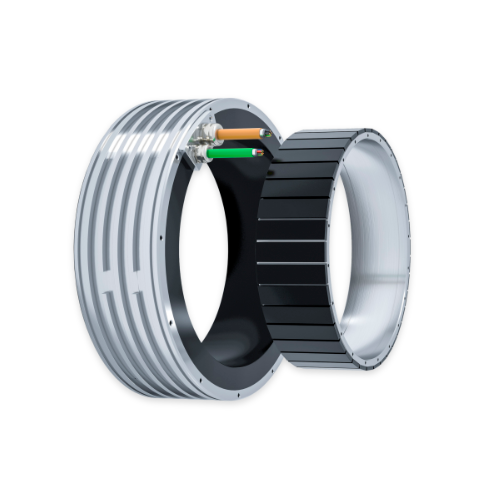

Torque motors

Increased dynamic performance of your application

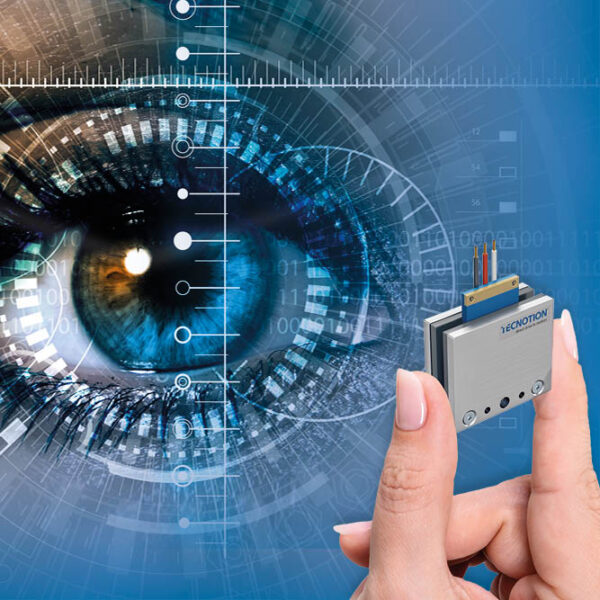

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Within life science, applications that are specifically suited for Tecnotion direct drive technology are for example surgical robots, sample handling, and rehabilitation equipment. What they have in common is that they all require precise motion control for the best results, in quality and throughput.

Designed for when every millimeter matters, but high-performance cannot be compromised.

Handling samples requires small, precise motors. The moving mass is typically low, so our small ironless motors are well suited for the task. The different magnet track sizes give maximum flexibility in total magnet track length. This flexibility in length fits well with modular laboratory equipment and process stations.

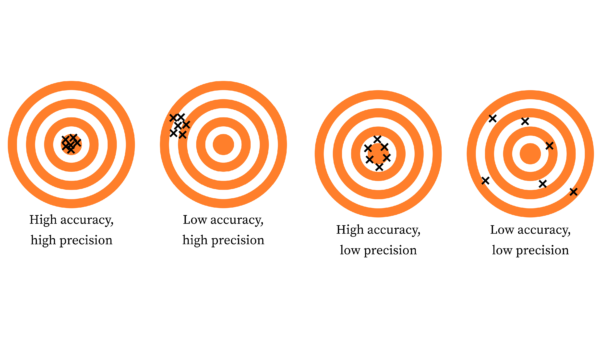

Surgical robots transfer the surgeon’s motion to the operating instruments. The quality of this transfer is affected by the accuracy & precision of the feed-forward motion as well as the quality of feedback motion: resistance encountered by the instruments is fed back to the surgeon’s controls. Using torque motors with low and predictable cogging provides the required precision, both in the manipulators of the surgical robot and for motion feedback for the surgeon. The quiet operation of the torque motor helps to minimize noise and improves the patients’ experience.

Exoskeletons help patients through their rehabilitation process by providing the most natural posture and movement support as the patient is regaining strength and control. Due to the compact size and large inner diameter, our torque motors can be combined with virtually all types of gearboxes to meet the torque requirements of exoskeletons. The compact size also leads to a high power-to-weight ratio, reducing the mass of the exoskeleton. Low voltage windings are available to run the motors to at battery level voltages.

Ironless motor |Brochure| 1.3

Torque motor |Brochure| Version 2.3

All linear motors |Brochure| Version 3.0

Iron core motor |Webinar| Version 1.0

Ironless motor |Leaflet| 1.0

Ironless motor |Leaflet| 1.1

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.