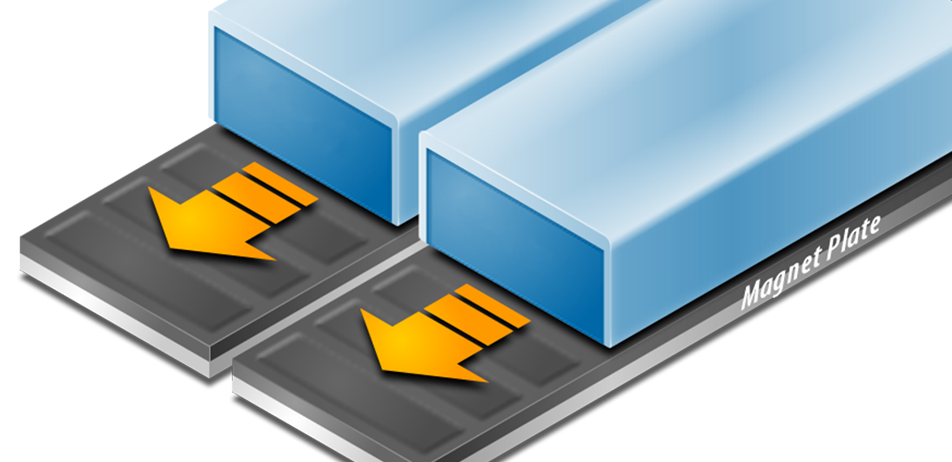

Does your machine need a power upgrade or do you want to expand an existing design? Coupling two or more iron core linear motors is an easy and effective way of increasing the available force. Herewith you are not just limited to using identical motors. Various combinations can be made, as long as the motor force constant is the same.

Cost effective

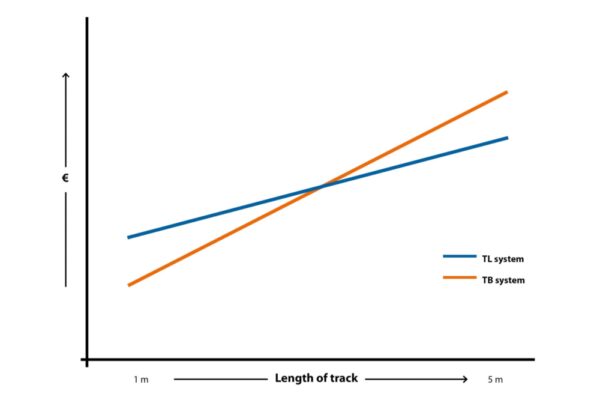

Besides the clear advantages of ‘more force’ in a coupled motors application, there are important cost and logistics advantages. Keeping an inventory of a similar coil assembly in stock for multiple machines and applications reduces costs and filed support issues. Existing designs can have multiple force capabilities standardizing on existing parts. As linear motor cost is a function of magnet size, using dual coils of a smaller motor significantly adds value. As a result, this advantage becomes more apparent for longer magnet tracks.

Conditions: Always connect motors to the drive in parallel – Use the correct spacing between the motors – The motor must have an identical motor force constant

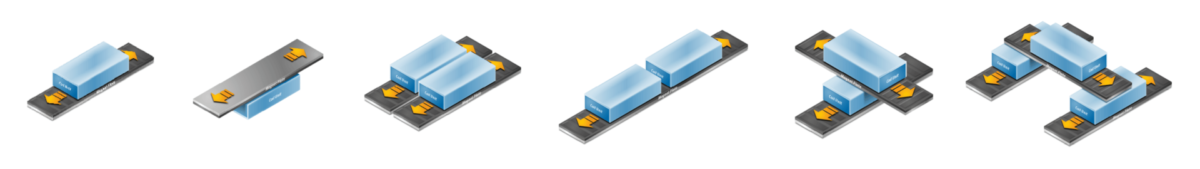

Possible couplings

Though the motors always have to be connected to a drive-in parallel, mechanically it is possible to align them in series or parallel. Motors can move on different magnet tracks to provide even force to a large gantry or on the same magnet track to improve the power in one line. In both cases, the total force of all motors equals the sum of individual forces. For more information, the iron core manual is available in our downloads menu. Our support team is available to answer all your questions on this topic.

Technical note – Advantages of coupling iron core motors

Ask us directly

Mike Rolink and Stefan Jansen

Application Engineers

“Do you have a question about a motor? Or do you need technical support during an installation? Call us and one of our Application Engineers will help and support you throughout the entire process.”

Ask your question