Linear motors

Unmatched acceleration and dynamic movements

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

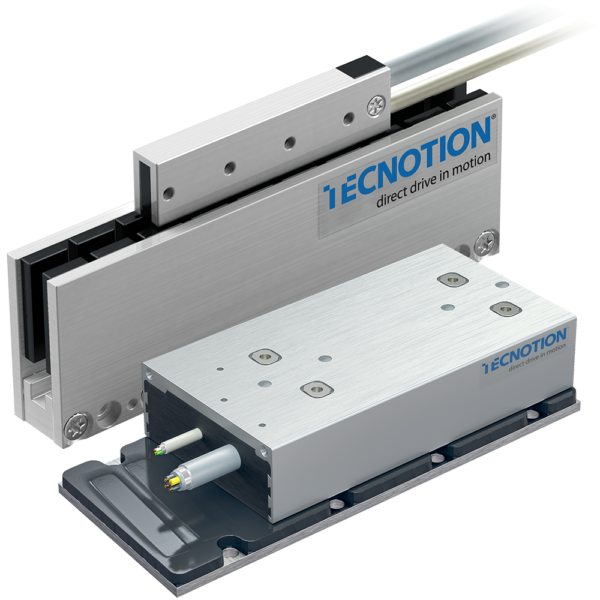

Iron core linear motors are becoming more prevalent in printing applications because these motors ensure high forces and therefore increase printing speed. Combined with the high precision of linear motors, it offers unsurpassed print quality.

Our iron core linear motors are well known for having the highest force density in the market, resulting in high forces and accelerations to move the printing heads. Typically, they move at around 10 m/s², allowing the printing head to run at the desired speed in no time. The full movement cycle is significantly shorter compared to traditional linear motion systems, enabling for higher throughput.

It is important that the accuracy of the motor position is perfect when paper going through a printer. To maximize printing accuracy, it is important to minimize motor cogging. Cogging is the phenomenon that linear motors have preferred positions over the magnet track. The unique design of our iron core magnet plates, where the magnets are slightly tilted, secures that the motor experiences low cogging. Our magnet and coil design combined with an anti-cogging algorithm allows the motor to have almost no speed ripple.

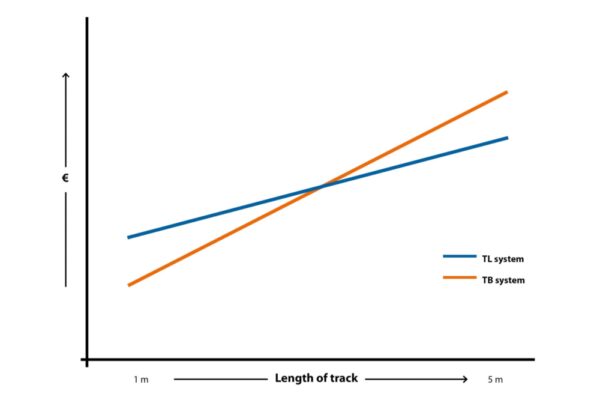

Most printing applications have long strokes and therefore require many magnet plates. To save magnet material, it is often beneficial to use a motor that is narrow . Specially for the long travel applications, we have developed the TL48, a motor that delivers high force while the system is more cost effective than TB equivalents due to its design of a longer coil unit and narrow magnet track.

With iron core motors it is possible to increase the throughput and quality of both single-pass and multi-pass printers, regardless of the material being printed on.

Printing also requires the substrate to remain at the correct tension. This can be achieved by QTR or QTL torque motors, which can be installed directly on the rotational axis. The print quality remains excellent from the first to the last centimeter.

All linear motors |Brochure| Version 3.0

All linear motors |Leaflet| version 2.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.