Linear motors

Unmatched acceleration and dynamic movements

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

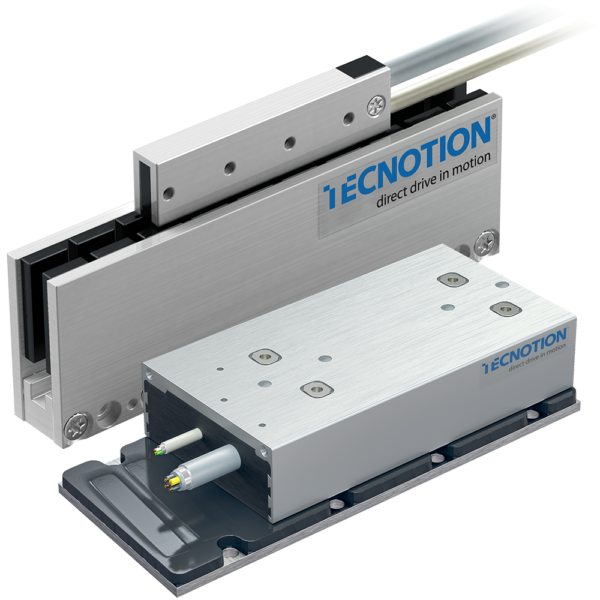

Direct drive motors enable highly dynamic and accurate movement for all kinds of system solutions. The compact design of linear and rotative brushless motors grant for a systems with a lower volume and improve throughput, accuracy and repeatability of the intended operation.

Direct drive motors offer very high accelerations and top speeds compared to other motion solutions. In combination with the low settling times, they enable system solutions to apply highly dynamic movement profiles and increase throughput.

They can also achieve very high accuracy and repeatability in the sub-micron range. Making it possible to achieve higher quality results.

High Accuracy and repeatability is ensured over the complete life time due to the absence of mechanical wear.

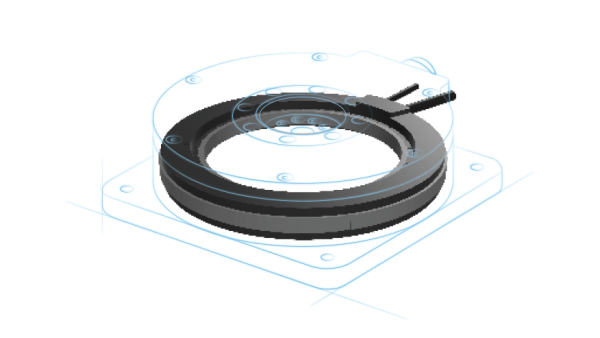

Tecnotion motors are optimized in terms of force/torque density thanks to their electromagnetic properties. The compact design and low build-in heights save space and enable a very compact system solutions. The large inner diameter of torque motors allow this space to be used for cable management and other functions such as optical beams.

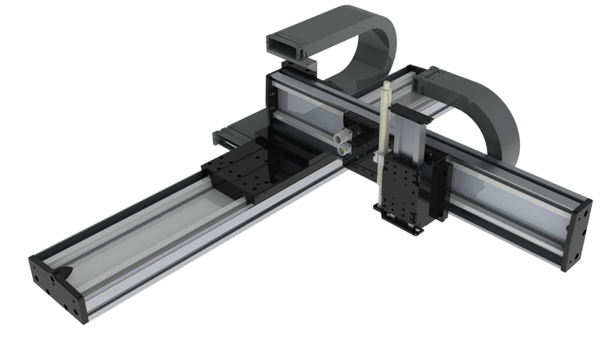

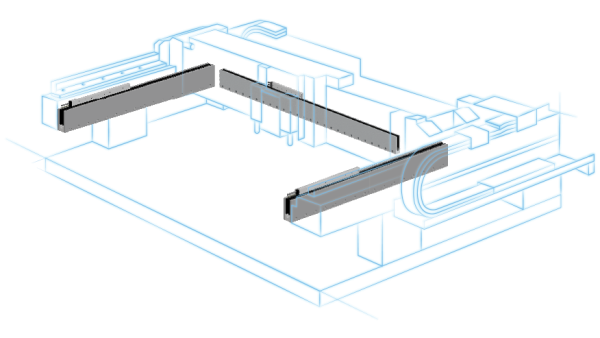

In the case of linear motion, multiple coil units can move independently of each other on a single magnet track. This provides flexibility in manipulating the workpiece using multiple tools in one machine platform.

Adjusting the work area is easy by adding or removing magnet tracks to adjust the length of the stroke. It is not necessary to adjust the control parameters. The modularity is also an advantage due to the use of different lengths of tracks. In this way, the stage length can be scaled and multiple heads can easily be created with additional coil units. This is especially beneficial when integrated into machine platforms of different sizes and carrier weights.

By placing several stages on top of each other, a multi-axis system can be created with different degrees of freedom.

Torque motor |Brochure| Version 2.3

Iron core motor |Webinar| Version 1.0

Torque motor |Webinar| Version 1.0

Iron core motor |White paper| Version 2.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.