To minimize the chance of unwanted chemical reactions or pollution of the process or surrounding equipment, more and more high-tech applications require vacuum solutions, such as

One of the biggest challenges in a vacuum environment is heat transfer and motion. The closed design of the Generation 2 vacuum motors is optimized for low heat dissipation and optimal mounting. These features allow an easy system design that is suited for the integration of multiple motors in one system.

Cost of Ownership

Linear vacuum-rated motors have no moving parts and are frictionless, this makes the motors maintenance-free. Tecnotion’s vacuum ironless motors can be placed in a high vacuum as a whole, and therefore require no feedthrough, which results in saving costs. The initial investment of vacuum linear motors can be higher than other drive systems but because of low maintenance costs, the total cost of ownership is reduced.

Extremely low outgassing

The production process can be affected by the outgassing of the motion system. The vacuum ironless linear motors are specially designed coil units and magnetic yokes for use in high vacuum, up to 10-8 mbar, and offer the lowest achievable outgassing for a series product.

The importance of low outgassing can be crucial for certain applications, that Tecnotion had this thoroughly tested and the support team can supply you with exact specifications and performance details.

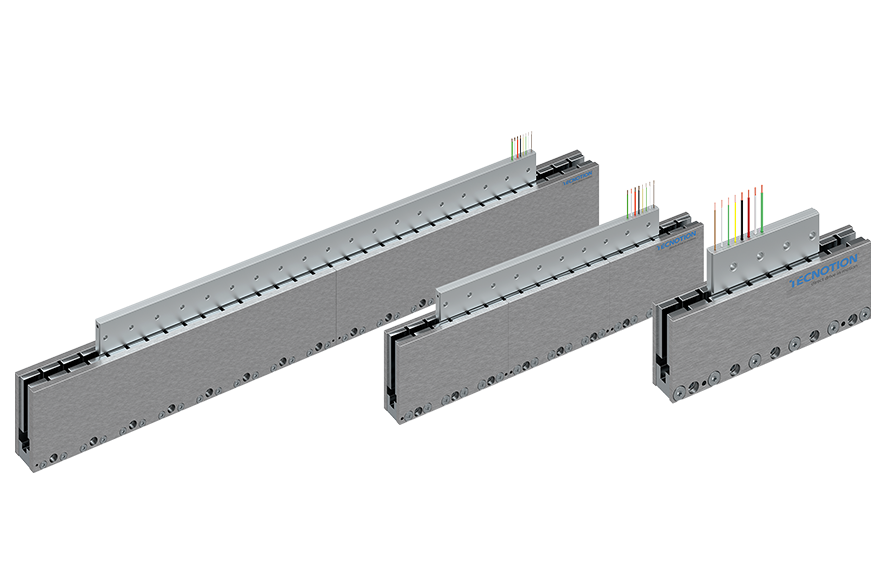

In addition to above vacuum motors, Tecnotion offers a diverse range of other vacuum linear motors

- Linear Motor Transport system using iron core or ironless motors.

- Customized linear actuator designed to customer requirements and, if required, the highest specifications available on the market.

View other vacuum rated products