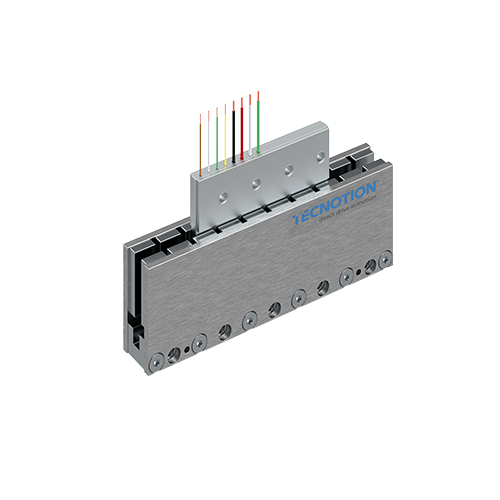

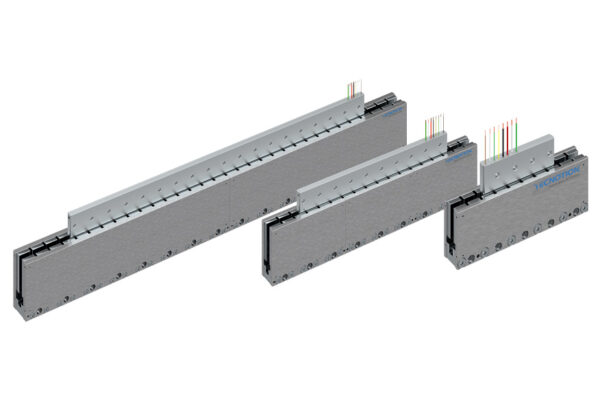

Vacuum G2 motors

For powerful and precise processes

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Tecnotion vacuum rated ironless linear motors are optimized in various ways to perform in very strict vacuum conditions to prevent unwanted chemical reactions, contaminations or influences due to magnetic stray fields on the process. Improvements are realized in the areas of outgassing, heat extraction and force generation.

Most industrial applications are in the high vacuum range to minimize the potential of unwanted chemical reactions or contamination of the process- and surrounding equipment. The coil unit and magnet yoke within vacuum linear motors are completely encapsulated by vacuum-compatible materials such as stainless steel and nickel coating instead of the typical polymer casting resin, which greatly reduces outgassing. Care has been taken to minimize magnetic stray fields which can adversely affect vacuum processes. Combined with a very efficient heat load transfer, which prevents loss of accuracy due to thermal expansion, the vacuum-rated motors have the best performance for stringent vacuum applications.

Outgassing is a process in which gas that has been dissolved, absorbed, or trapped is released through the process of sublimation, evaporation, desorption, or seepage. In a vacuum environment, the gas is released into the vacuum. This means that the effective pumping speed must be increased to maintain a certain vacuum level as the outgassing increases.

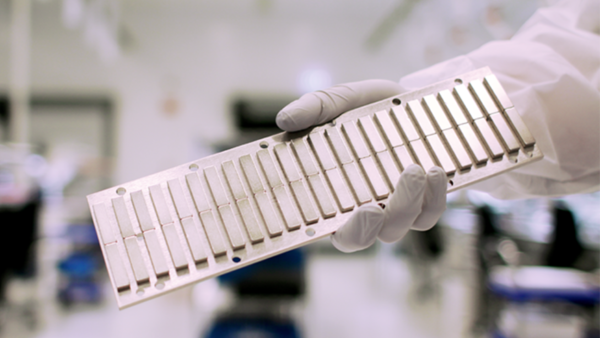

Materials found in the coil units and magnet yokes/tracks of direct drive motors, such as the resin, magnet adhesive, and cable jacket have relatively high outgassing values. Tecnotion vacuum motors are enclosed with a material that has greatly reduced outgassing values, making them suitable for vacuum environments. Because the motors are wholly or partially sealed with a stainless steel or aluminum jacket and the enclosed magnets are coated with a nickel alloy, this prevents the trapped gas from leaving and entering the vacuum.

A virtual leak is a gas source that is trapped but is able to gradually escape from its pocket as the pressure in the environment decreases. One of the most common examples of a virtual leak is the gas that is trapped in a blind tapped hole with a screw inserted. Virtual leaks cause a higher gas load that must be pumped out to reach a certain vacuum level. At a higher gas load, a higher effective pump speed is needed to reach the desired vacuum level. Tecnotion vacuum-rated motors are designed with attention to minimizing virtual leaks.

In addition to outgassing and virtual leaks, ensuring the cleanliness of the products placed in a vacuum environment is an important property to ensure that there are no contaminants and/or dust particles that adversely affect the vacuum environment and intended process. Tecnotion follows a strict protocol to ensure that a high level of cleanliness is achieved when the vacuum motors are shipped. The protocol includes the use of materials suitable for use in vacuum to reduce carbohydrate outgassing, the use of tools and equipment during handling to minimize contamination, cleaning of the products and shipping in double packaging.

Extracting heat from a vacuum chamber is major challenge due to the absence of convection and only conduction and radiation remain as modes of heat transfer. Tecnotion vacuum rated motors are designed to efficiently conduct heat away from the coil units, as is reflected by the low thermal resistance, which increases the maximum possible force generation.

Tecnotion offers a range of motors specially defined for vacuum environments to meet the unique challenges and solutions for these applications. Central to this is optimization of the motor performance with regard to outgassing properties, heat extraction and cleanliness.

The vacuum rated motor properties ultimately results in shorter vacuum chamber evacuation times and the ability to use smaller vacuum pumps to achieve the desired vacuum levels. This saves time and equipment costs, increases throughput and reduces rejects due to manufacturing and process errors.

Vacuum motor |Brochure| 1.4

Torque motor |Brochure| Version 2.3

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.