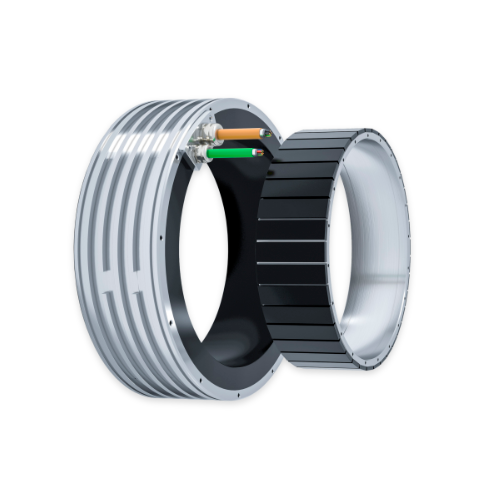

Torque motors

Increased dynamic performance of your application

ExploreMinimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Woodworking applications are typically characterized by high-force outputs and dirty environments, making large iron core and torque motors interesting for these applications. Before the machining takes place direct drive motors are also interesting for indexing and scanning.

In the woodworking industry, horizontal panel beam saws cut large sheets, strips, or panels of wood or wood-based materials into various sizes. The cuts are made by a saw mounted on a carriage, which can be driven by linear motors, resulting in high velocity, acceleration, and thus high throughput.

In addition to increased dynamic performance, a low-cogging iron core motor ensures smooth motion of the carriage and saw, avoiding harmful vibrations that would reduce the quality of the cut. Linear motors have the additional benefits of reduced noise, increased efficiency, no maintenance, no loss of dynamic performance over time, and unlimited cutting lengths.

Before the wood is cut, the wood quality is regularly observed, usually with the help of a CT scan. This is often done with linear motors, due to the high precision of these motors.

The wood needs to be indexed before and after cutting, which is often accomplished by torque motors. Because precision and high stall torque are important at this stage, torque motors are the ideal solution. Also in other processing lines, e.g. peeling and repairing, torque motors are used to do the rotary movement.

Torque motor |Brochure| Version 2.3

Iron core motor |Webinar| Version 1.0

Torque motor |Webinar| Version 1.0

All linear motors |Leaflet| version 2.0

Finding the right motor for a given application can be a daunting task. It involves a large number of interconnected design choices. The motor Simulation tool is designed to make that process as easy as possible for you.