All linear motors |Brochure| Version 3.0

Moving magnet systems

Minimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

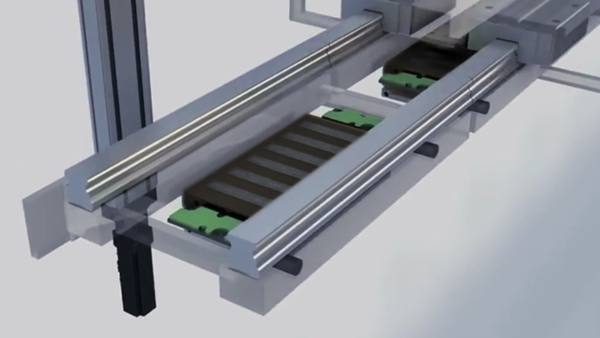

For applications that require non-contact, particle-free transport, such as clean rooms, vacuums, or chemical environments, a moving magnet linear motor meets the most demanding process requirements.

In the case of clean room and vacuum applications, any particle-generating components must be positioned outside of the controlled environment to avoid degrading the environment. For applications that involve the presence of hazardous chemicals, safety requirements demand that electrical components be located outside of the work area. The moving magnet system, jointly developed by Tecnotion and a motion control partner, provides the perfect solution to these requirements.

This assembly includes an iron core linear motor with a moving magnet plate (secondary part), which is installed in the working environment and provides transport. The unique feature of the moving magnet system is that the coils (primary part), along with the electrical components, are located outside the process area and remain stationary. As with standard iron core linear motors, the magnet plate and coils are separated by an air gap, but in this case, the gap is larger than that of a standard linear motor, to allow room for the vacuum chamber wall that separates them. The air gap is one of the factors that affects linear motor performance, including the motor’s K-factor. Tecnotion specifies the K-factor of its linear motors at 0.5mm air gap and a heat sink temperature of 20 degree Celsius.

The moving magnet system offers all the traditional advantages over rollers, chains, or belt transport systems – higher stiffness, better accuracy, and higher acceleration. But it also allows the use of multiple, independently controlled carriages and a high level of scalability and flexibility for cost-effective integration with a machine or production line. One down side of the moving magnet system is that the cost-per-meter can be high due to the separate coils and electric drives required for each coil. But the main advantage of this system is the location of the electrical components and particle-generating parts outside of the working environment, which ensures safety and production reliability.

Tecnotion direct drive motors are seamlessly integrated into a wide variety of applications, such as semi-conductors, machine tooling, robotics, display applications and printing industry. We direct drive your motion technology.

All linear motors |Brochure| Version 3.0

Iron core motor |Manual| version 2.1

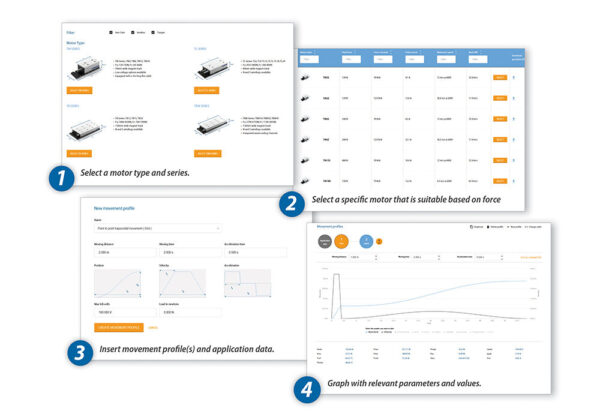

Find the best motor according to your application criteria. Select a product type and choose relevant values to filter the most suitable motor.

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.

Contact us for your custom motor

Thank you for your interest in our motors. Please fill out the form to request more information about customized or tailor-made motors and one of our experts will get back to you.