Torque motor |Brochure| Version 2.3

Curved magnet track - Customized motors

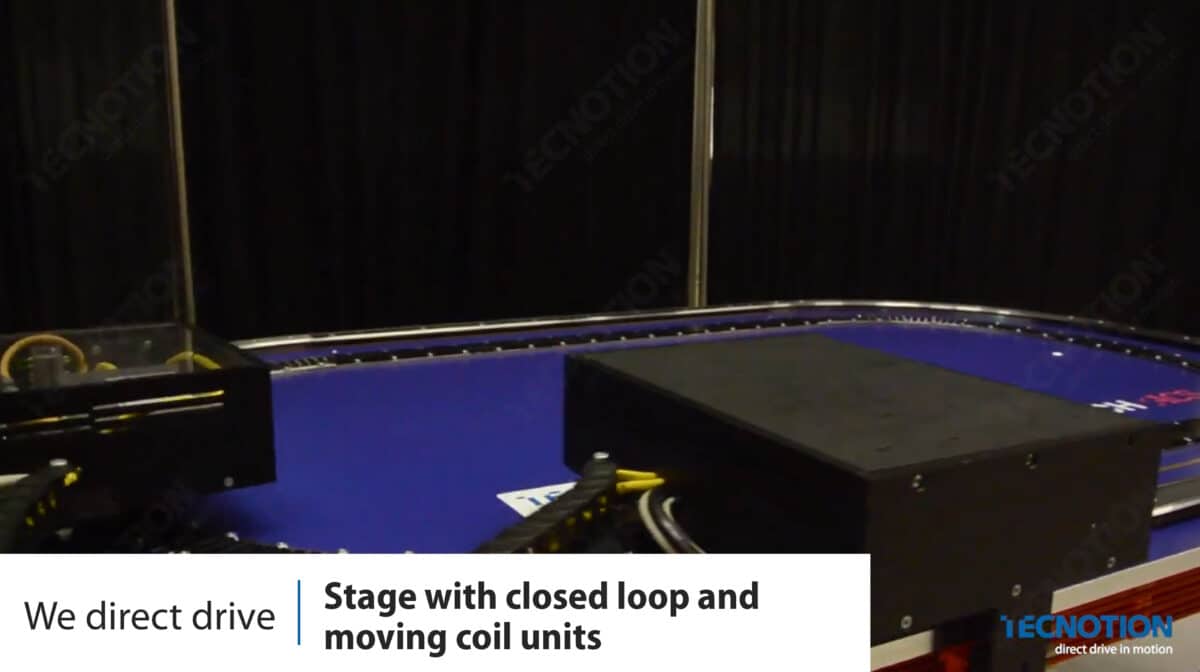

While machines are often designed with strictly linear motions in mind closed tracks are interesting for many applications.

With the curved magnet plate design from Tecnotion many more versatile track configurations are possible.

The curved magnet plates have an intelligent design that compensates for force losses in the curves due to commutation error, which occurs due to straight coils on curved tracks. Standard motors can be used which have a low attraction force for their continuous force exerting low wear on the bearings. They also have low cogging which gives a very smooth motion in combination with a cogging compensation algorithm for the curved sections.

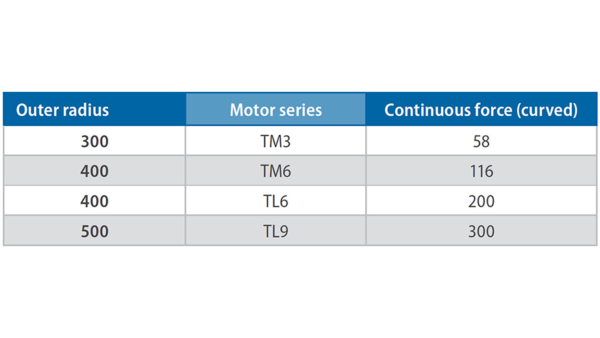

Tecnotion can deliver up to 2000N of continuous force depending on diameter. The curved sections are interesting for many packaging, transportation, and other applications.

How does a linear motor move over a curved track? A seemingly complicated question with straightforward answers. Where traditionally different motion systems can be used to follow up on a linear motion, Tecnotion develops curved magnet tracks. These tracks allow more complicated curved movements using a ‘traditional’ linear coil unit.

Tecnotion developed the curved tracks to minimize force losses. Electromagnetic design provides low cogging, and by using the right algorithms, allows very smooth motion. Especially transport and packaging systems can benefit from a curved magnet track. Curved magnets enable the possibility of creating a closed track entirely from direct-drive linear motor parts. In particular systems with continuous flow and with more motors on one track can achieve higher efficiency using closed-loop curved magnet tracks.

Customizable

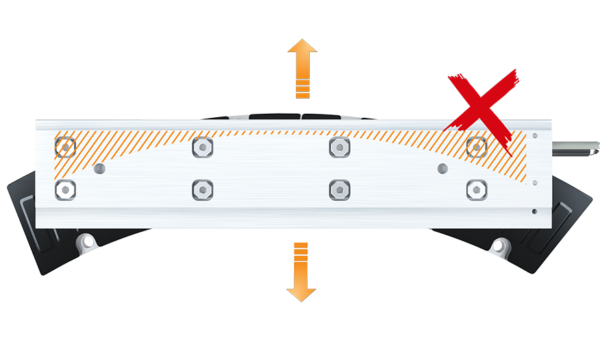

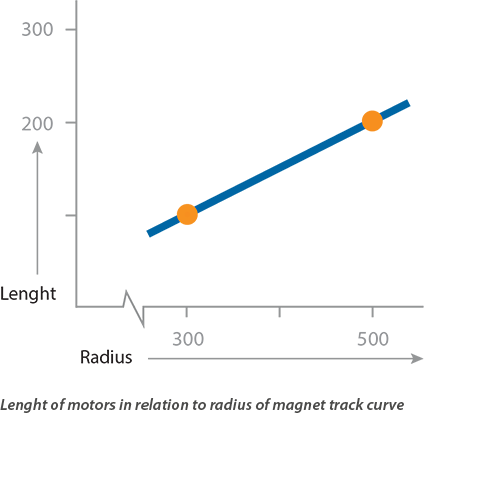

There are existing curved magnet designs at hand, specifying a radius and magnet track width. Large projects with curved magnet tracks are highly customizable thanks to these designs. Depending on specific customer requests, Tecnotion can adapt the design, radius and number of segments required to make any curved track. We will advise the correct radius depending on the coil unit needed. When the radius is too small or the motor is too long, movements will become unpredictable (side-to-side and/or force variations).

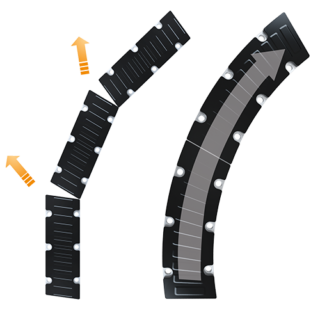

Unpredictable moving and force loss occurs when the motor is too long for the curves

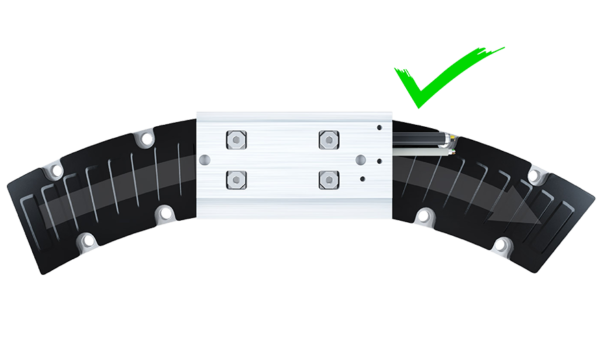

Perfect fit with optimal force ratio

Possibilities and opportunities

Curved magnets provide opportunities for transport, packaging, and more. Tecnotion’s standard linear motors can be used in a closed-track system. Closed tracks allow for continuous workflow and multiple coil units on one track. Giving the potential to use an existing track much more efficiently. The individual motors can be driven at different speeds and in different directions. Compared to a traditional conveyor belt, products can be slowed down for quality inspection and/or sorting processes. The product can be sped up immediately afterward to not disturb the overall workflow. Individual motors can be powered by sliding contacts for maximum versatility.

Upon designing a curved magnet application, it is important to look at the bending radius. Keep in mind the radius has to be sufficient for the motor to move correctly. The minimum magnet-radius (center) of the track is approximately 275 mm. Designs can be optimized by varying in the number of curved magnet segments used to complete a track.

Left: Some systems use regular straight magnet tracks to form a curve. Even though the motor will move, movement and vibration become very unpredictable and a lot of force can be lost in these movements. The magnets are not at ‘set’ distances.

Right: The Tecnotion design has precisely placed magnets to provide smooth movement through the entire curve.

Advantages

A curved magnet iron core system provides unique characteristics. What advantages they provide for your system depends on what parts the curved magnet track replaces. There is no direct comparison to be made between any current system and the iron core on a curved magnet track.

In short, the curved magnet track is:

- Cost-effective and less complex to control by using one motion system to control all movements.

- Delivers a higher continuous force than a moving magnet solution.

- Maintenance is friendly and mechanically simple compared to a ‘combined system’ of belts and linear motors.

- Far higher force than a curve made with straight magnet sections.

- More versatile and free of movement than a transport belt and can use multiple motors on one track. For this application a sliding contact to power the motor can be beneficial.

- Opportunity to use a continuous workflow instead of moving back and forth on a traditional linear motor track.

- More versatile than a large torque motor, the possibility to use only a 90 or 180-degree curve and multiple coil units.

With a curved magnet iron core system, it is always important to pay close attention to the radius related to motor length. A certain motor length is needed to provide force to the application. This motor length will be the deciding factor in the possible radius. The Tecnotion TM3 (51×93 mm WxL) can for instance be used on a track with a 300 mm outer radius. Small deviations can be made by choosing a different track width and making concessions on the motors’ force. For full flexibility in movement a slide can be used to power the motor, flexible cables are a more limiting option. The Tecnotion TM, TL, and TB / TBW coil units are very capable when used on a curved track. When using the correct design, power loss is minimal. Usually Tecnotion advises a design with a power loss of 5% or less.

With a curved magnet iron core system, it is always important to pay close attention to the radius related to motor length. A certain motor length is needed to provide force to the application. This motor length will be the deciding factor in the possible radius. The Tecnotion TM3 (51×93 mm WxL) can for instance be used on a track with a 300 mm outer radius. Small deviations can be made by choosing a different track width and making concessions on the motors’ force. For full flexibility in movement a slide can be used to power the motor, flexible cables are a more limiting option. The Tecnotion TM, TL, and TB / TBW coil units are very capable when used on a curved track. When using the correct design, power loss is minimal. Usually Tecnotion advises a design with a power loss of 5% or less.

Resources

All linear motors |Brochure| Version 3.0

FAQ

Product filter

Find the best motor according to your application criteria. Select a product type and choose relevant values to filter the most suitable motor.

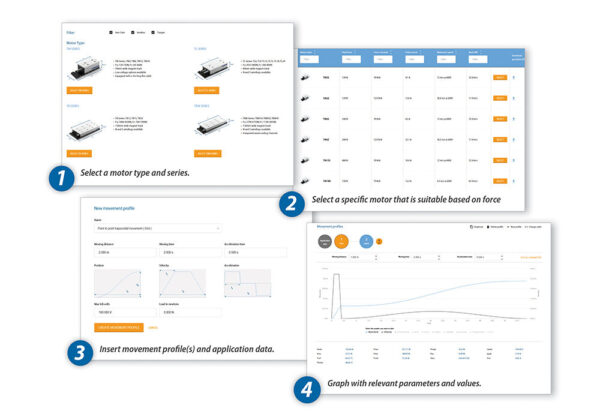

Simulation tool

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.

Our team of Application Engineers can advise in all your future plans for curved magnet tracks. Do not hesitate to contact us at sale@moto-tool.com or +31 546536300.

Contact us for your custom motor

Thank you for your interest in our motors. Please fill out the form to request more information about customized or tailor-made motors and one of our experts will get back to you.