Torque motor |Brochure| Version 2.3

Closed track transport system

Minimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

Machine throughput and production rate is a key factor for efficient manufacturing. It is well known that building machines that move back and forth result in lower efficiency than unidirectional movements.

The solution for a closed track transport system delivers many advantages over moving magnet transport systems. Accuracy in this solution is higher compared to moving magnet transport systems. The response time is considerably better because there are no issues with latency due to direct feedback of the encoder to the drive. They also allow to have a sinusoidal commutation instead of complex commutation profiles and have easy control due to the moving coil setup. Finally, the cost per meter is significantly lower.

The track can be made in several shapes, like oval, circular and square with curved corners. The possibilities are endless. Applications can be found in packaging, factory automation, assembly stations, digital printing, lab automation, hexapods, systems in need of a pitchless conveyor design and applications with no human interference.

The curved magnet plates have a smart design that compensates for force losses in the curves due to commutation error, which occurs due to straight coils on curved tracks. The motors have a low attraction force in respect to their continuous force exerting low wear on the bearings. The motors also have low cogging which gives in combination with the cogging compensation algorithm a very smooth motion in the curves. Tecnotion can deliver up to 2000N of continuous force depending on diameter.

Technology now allows machine designers to benefit from the dirt immunity and mechanical tolerances of magnetic technology without the need to compromise on measuring accuracy. The motion control solution fully supports on-the-fly switching from analog hall feedback to linear encoder feedback, while maintaining the same engineering units defined by the user regardless of the feedback in use.

Torque motor |Brochure| Version 2.3

All linear motors |Brochure| Version 3.0

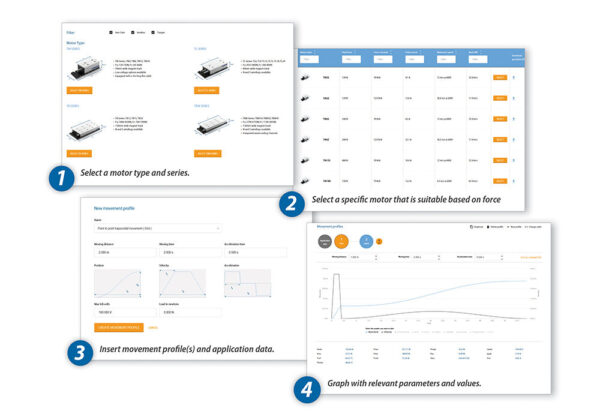

Find the best motor according to your application criteria. Select a product type and choose relevant values to filter the most suitable motor.

Finding the right motor for a given application can be a daunting task. The online simulation tool is designed to make that process as easy as possible for you. Find the right motor in just 4 steps.

Contact us for your custom motor

Thank you for your interest in our motors. Please fill out the form to request more information about customized or tailor-made motors and one of our experts will get back to you.