2026 Top Home Laser Cutter Machine Options for Every Maker?

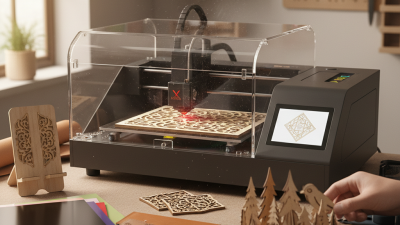

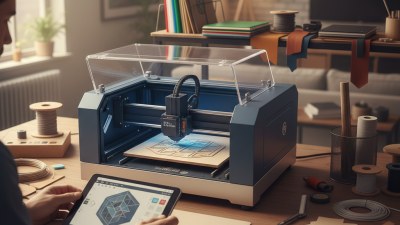

In recent years, the demand for a home laser cutter machine has surged. These versatile tools empower makers to create diverse projects, from intricate designs to functional items. With advancements in technology, many options are available to suit different skill levels and budgets.

Choosing the right home laser cutter machine can be overwhelming. Some models excel at precision, while others offer speed and user-friendly features. Additionally, it’s essential to consider space constraints and safety features. Not all machines are created equal, and this can lead to frustration.

Many makers face challenges when selecting the perfect machine. Ensuring compatibility with materials is vital. Some models struggle with thicker materials or specific types. Reflecting on your goals can help guide your decision. The landscape of home laser cutters is evolving, and understanding what each offers is crucial for a successful investment.

2026 Market Trends in Home Laser Cutter Technologies for Makers

The landscape of home laser cutter technology is rapidly evolving. In 2026, makers can explore a variety of user-friendly options. These devices are smaller and more efficient than ever. They incorporate advanced sensors and software to improve usability. Some models allow for wireless connectivity, enhancing the crafting experience. Additionally, the price of entry-level machines is decreasing, making them accessible to more hobbyists.

However, not all laser cutters are created equal. Some may lack precision, leading to unsatisfactory results. Makers should consider the importance of resolution and engraving speed. A cutting machine that works well for one project may not fit another. The need for trial and error is a constant. Users may find themselves frustrated with setup issues or software compatibility.

As makers delve deeper into the world of home laser cutting, staying informed is vital. Understanding market trends can prevent costly mistakes. The community offers valuable insights. Networking with fellow enthusiasts can reveal hidden gems and common pitfalls. Embracing imperfections can lead to growth and innovation in this exciting field.

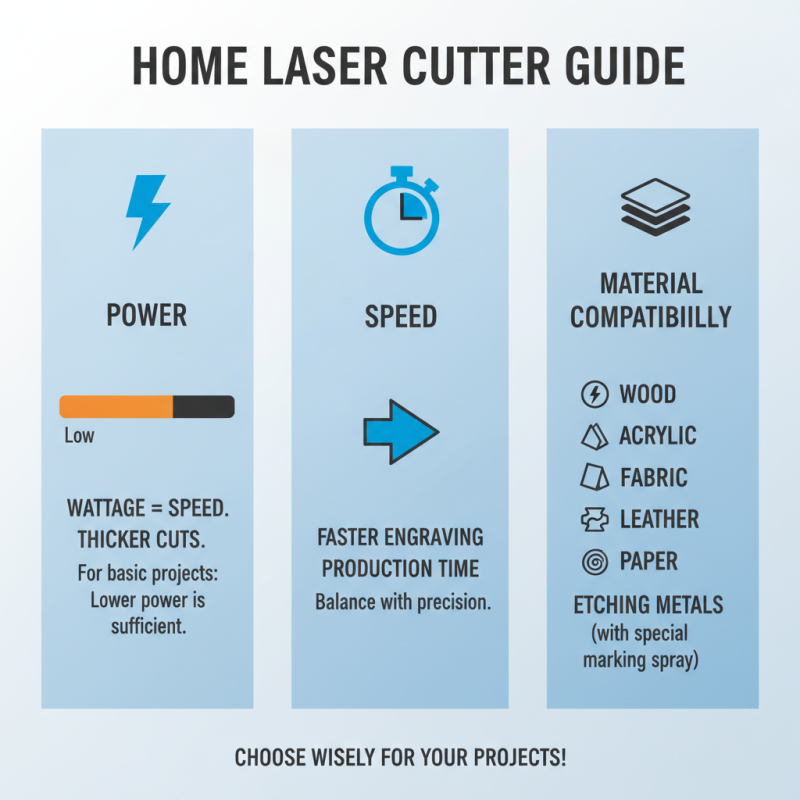

Key Features to Consider When Choosing a Laser Cutter for Home Use

When choosing a laser cutter for home use, consider several key features. These include power, speed, and material compatibility. A machine's power level often dictates its capabilities. Higher wattage means faster cutting and engraving. However, high power may not always be necessary for basic projects. Small pieces, like intricate designs, could require less intensity.

Speed is another important factor. Some machines operate slower yet produce high-quality results. However, balance is crucial. Fast machines often compromise detail. You should assess what is most important for your projects. If precision matters, a slower cutter might serve better.

Tips: Always check the machine's cutting area. A larger workspace enables larger projects. Furthermore, explore the software compatibility. Some systems require specific software to operate. Make sure you can work with what you have.

Do consider noise levels too. Some laser cutters can be quite loud. Assess whether the noise will disrupt daily life. Also, reflect on your skill level. Beginners may benefit from user-friendly models. Advanced users may want more capabilities, even if they come with a learning curve.

Comparison of Leading Laser Cutter Brands with Market Share Data

In the rapidly evolving world of laser cutters, makers have multiple options for their projects. Evaluating the market share of different brands shows varying strengths. Some brands lead in affordability, while others excel in precision. Data reveals that certain options dominate in both sales and user satisfaction. However, many makers struggle to find the perfect balance between cost and performance.

User reviews often highlight common issues. Some models may lack consistency in beam quality. Others might be more challenging to use, especially for beginners. It's essential for users to rethink their preferences. Choosing a more complex machine could lead to frustrations without proper knowledge. On the other hand, simpler models might not offer the needed versatility for diverse projects.

Amidst competition, the user experience also varies significantly. Certain features that seem appealing on paper can turn out to be less effective in real-world applications. Makers should reconsider their priorities. Focusing solely on brand reputation can lead to disappointment. Analyzing specific needs may provide better insights than general popularity trends.

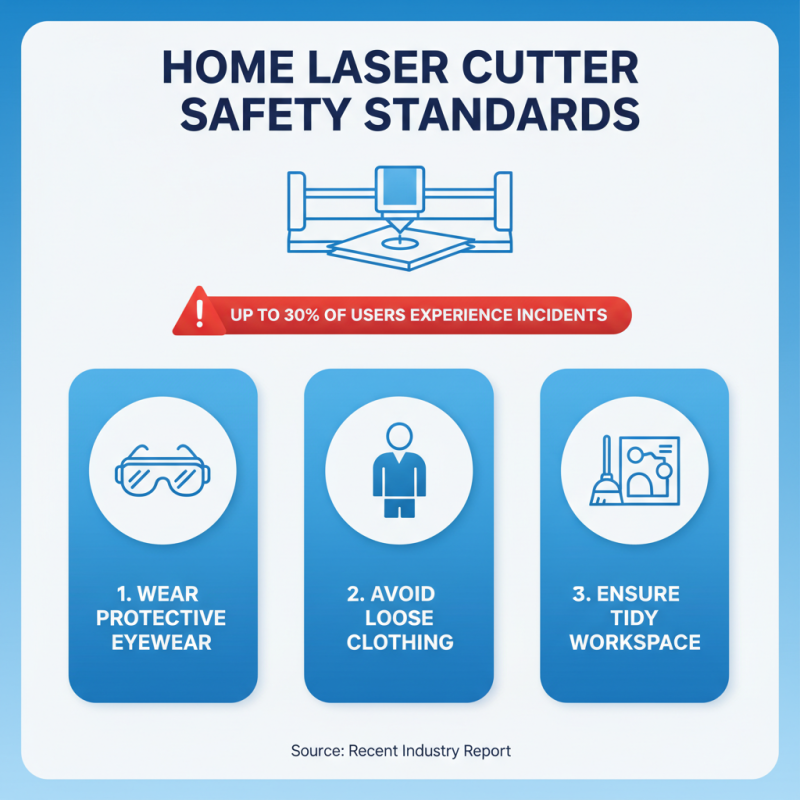

Safety Standards and Best Practices for Home Laser Cutting Machines

When considering home laser cutting machines, safety standards are crucial. According to a recent industry report, up to 30% of laser cutter users experience safety-related incidents. This alarming statistic highlights the need for stringent safety practices. For instance, always wear protective eyewear when operating a laser cutter. Avoid loose clothing and ensure your workspace is tidy. These simple precautions can significantly reduce potential hazards.

To enhance safety, it's essential to install proper ventilation in your workspace. The fumes produced during laser cutting can be harmful. A well-ventilated area minimizes harmful exposure. Regular maintenance of your machine is also key. Inspect your equipment for any wear or damage before each use to prevent accidents.

Another critical aspect is understanding your machine's capabilities and limitations. Not every material is suitable for laser cutting. For example, cutting acrylic requires specific settings to avoid excessive melting. Always refer to operation manuals and material guides for best practices. Remember, a moment of carelessness can lead to serious consequences. Prioritize safety and be mindful of your surroundings.

User Reviews and Reliability Ratings of 2026 Laser Cutter Models

In 2026, the market for home laser cutters is expanding rapidly. User reviews reveal a mixed bag of experiences across different models. Many users praise the precision and speed of these machines. However, reliability remains a concern. Some users report frequent breakdowns and long wait times for customer support. A recent industry report indicates that over 30% of buyers faced issues within the first six months.

User ratings vary greatly. Many products receive high marks for functionality but lower scores for durability. It’s crucial to analyze user feedback before making a choice. Look for models that have consistently good reviews over several months. This approach can help avoid unsatisfactory purchases.

Tips: Before you buy, check return policies. Some models may not meet expectations upon use. Always look for warranties and customer service ratings. Additionally, consider the maintenance costs. An inexpensive machine may turn out to be costly in the long run due to repairs. Prioritize options that have positive long-term feedback from actual users. This helps ensure a satisfying experience.