2026 Top Fiber Laser Cutter Innovations You Should Know?

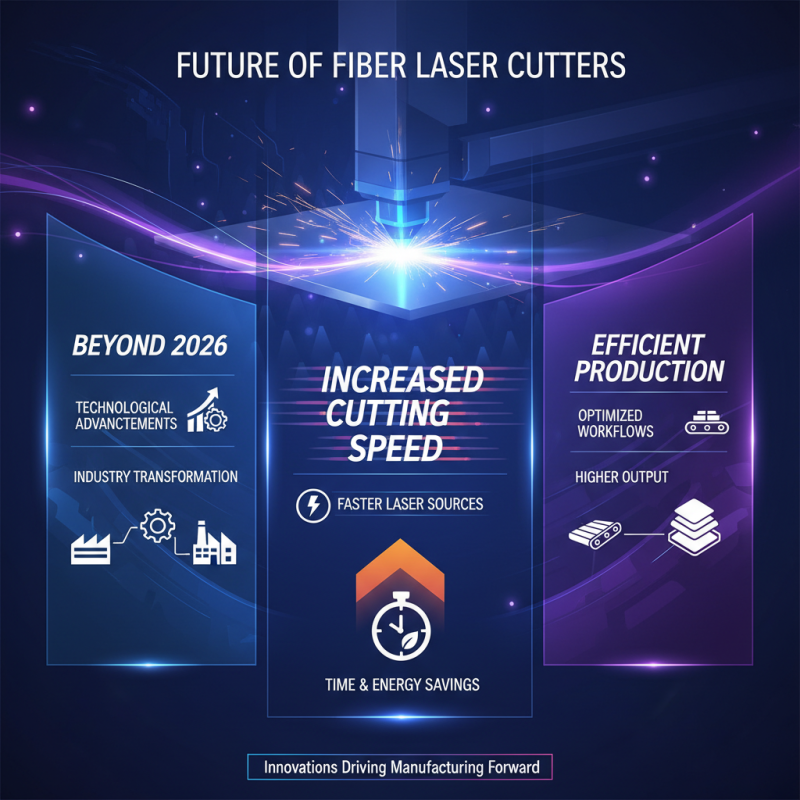

As the industrial landscape evolves, fiber laser cutters have emerged as a revolutionary tool in manufacturing. These machines offer unprecedented precision and speed. According to a report by Markets and Markets, the fiber laser cutting industry is expected to reach $4.4 billion by 2026, showcasing a significant demand for innovative technology. Experts emphasize the impact of these machines on various sectors, from automotive to aerospace.

Dr. Emily Carter, a leading authority in laser technology, stated, “Fiber laser cutters are transforming the way industries approach fabrication.” This highlights the profound shift in efficiency and effectiveness that these tools bring to production lines. However, not all companies are ready to adopt this technology. Some face challenges with integration and training, leading to underutilization of their fiber laser cutters.

Innovation in fiber laser cutting will continue to drive industry growth. Companies must stay informed about the latest advancements. Embracing this technology is not just about purchasing a machine; it’s about understanding its potential. As the market grows, so too should the strategic approaches to harnessing fiber laser cutting capabilities.

Overview of Fiber Laser Cutter Technology Advancements in 2026

Fiber laser cutter technology is evolving rapidly in 2026. Advancements focus on speed, precision, and energy efficiency. According to recent reports, cutting speeds have increased by 20% compared to previous years. This means faster production times, which is crucial in a competitive market.

Moreover, the integration of AI and machine learning is transforming operations. These technologies enable predictive maintenance and process optimization. Studies have shown a reduction in downtime by up to 30% with these innovations. This efficiency is critical for businesses aiming to lower operational costs.

However, the industry still faces challenges. Many companies struggle to adapt to these high-tech machines. Training staff is a notable issue. The gap in skills can lead to inefficiencies. It's clear that while advancements are impressive, the transition to these innovations needs careful planning and execution.

Key Features Enhancing Precision and Efficiency in Fiber Laser Cutters

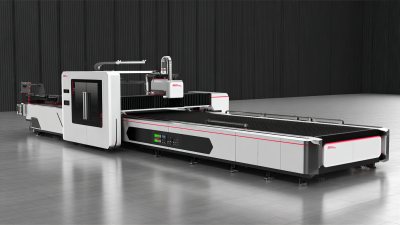

The landscape of fiber laser cutting technology is evolving rapidly. Innovations are focusing on enhancing precision and efficiency. One major feature is the integration of real-time monitoring systems. These systems can adjust parameters instantly, ensuring optimal cutting conditions. This dynamism allows for better performance in varying materials, enhancing overall productivity.

Another critical enhancement is the development of advanced optics. New lens designs and coatings improve light transmission and reduce losses. This leads to sharper cuts and can minimize material waste. Users often notice a significant difference in edge quality, which is crucial for automated assembly processes. However, implementing these technologies may require additional training.

Lastly, software advancements cannot be overlooked. Intuitive interfaces and AI-driven algorithms simplify operation. They allow operators to focus on complex tasks rather than routine adjustments. Yet, these systems can be complex. They might not be suited for every user, especially those accustomed to traditional methods. Balancing innovation with usability is essential for industry-wide adoption.

2026 Top Fiber Laser Cutter Innovations You Should Know

| Feature |

Description |

Benefits |

Applications |

| Auto-Focus Lens |

Dynamic lens adjustment for optimal focus. |

Increased cutting speed and precision. |

Sheet metal cutting, intricate designs. |

| High-Power Lasers |

Lasers exceeding 10kW for thicker materials. |

Enhanced cutting efficiency. |

Heavy industrial applications, thick plate cutting. |

| Smart Features |

AI and IoT integration for smarter operation. |

Reduced downtime, predictive maintenance. |

All industries utilizing automation. |

| Multi-Functionality |

Ability to cut, engrave, and mark. |

Versatile usage across different projects. |

Signage, decorative items, industrial parts. |

| Advanced Cooling Systems |

Efficient thermal management of laser components. |

Increased laser longevity and reliability. |

Industries with high production rates. |

Innovative Software Solutions Driving Fiber Laser Cutting Performance

Innovative software solutions are shaping the future of fiber laser cutting. These advancements enable operators to achieve greater precision and efficiency. Real-time monitoring tools help detect issues immediately, reducing downtime and material waste. The integration of artificial intelligence enhances decision-making, adjusting power settings for optimal cutting quality.

However, these innovations come with challenges. Users must adapt to new interfaces that can appear complicated at first. Training is essential to fully leverage these advanced tools. Additionally, data security becomes a concern when using cloud-based software. Protecting sensitive information should be a priority for organizations.

Maintenance of the software is also important. Regular updates can prevent glitches, but they require time and resources. Companies must balance innovation with user comfort and system stability. The future of fiber laser cutting hinges on overcoming these hurdles while embracing technological progress.

2026 Fiber Laser Cutter Innovations Performance

This chart displays the performance improvements in fiber laser cutting technology for 2026, showcasing innovations in speed, precision, and operational efficiency. The data represents the advancements made in these categories over the years.

Sustainability and Eco-Friendly Practices in Fiber Laser Cutting

Sustainability is crucial in today's manufacturing processes. Fiber laser cutting, known for its efficiency, offers eco-friendly advantages. It uses less power and generates minimal waste compared to traditional cutting methods. This means businesses can reduce their carbon footprint significantly while maintaining performance levels.

However, challenges remain. While fiber lasers are energy-efficient, the production of laser machines still involves significant resources. The materials used must be sustainably sourced. Additionally, operators need proper training on recycling and waste management. Mismanagement can lead to environmental issues, undermining the benefits of fiber laser technology.

The move toward greener practices is promising but not flawless. Companies need to commit to continuous improvement. Investing in innovative technologies is essential, yet the responsibility doesn't end there. Adopting a holistic approach towards sustainability is crucial to truly benefit from fiber laser cutting in a world striving for eco-friendliness.