2025 Top 5 Direct Drive Linear Motors: Revolutionizing Precision Engineering

In recent years, the precision engineering sector has witnessed significant advancements, particularly with the advent of

direct drive linear motors. These innovative devices have transformed motion control, ensuring higher efficiency and accuracy across various applications.

According to a report by MarketsandMarkets, the direct drive linear motor market is projected to reach $XX billion by 2025, growing at a CAGR of

YY%. This growth reflects the increasing demand for high-performance machinery in industries such as aerospace, robotics, and semiconductor manufacturing.

Direct drive linear motors offer distinct advantages over traditional systems, including reduced mechanical complexity, lower maintenance costs, and enhanced responsiveness. As highlighted in a comprehensive study by

Research and Markets, the adoption of direct drive technologies is expected to streamline production processes and improve product quality, a necessity in today's competitive landscape.

As we delve into the top 5 direct drive linear motors set to revolutionize precision engineering by 2025, we will explore their features, benefits, and the transformative impact they could have on manufacturing efficiency.

Advancements in Direct Drive Linear Motor Technology: Key Features and Benefits

The advancements in direct drive linear motor technology are transforming precision engineering, particularly in sectors such as semiconductor manufacturing and robotics. According to a recent report by MarketsandMarkets, the direct drive motor market is projected to reach $6.87 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.3%. This surge is driven by the need for high-speed automation and increased efficiency in production processes. Direct drive linear motors eliminate the friction associated with traditional mechanical systems, enabling smoother and more precise motion control.

Key features of these motors include high acceleration capabilities and linear motion without mechanical transmission losses. This intrinsic ability allows for a higher throughput in manufacturing environments, reducing cycle times significantly. For instance, systems utilizing direct drive technology can achieve up to 300% faster movements compared to conventional motors, according to research from the International Federation of Robotics. Furthermore, the integration of advanced control algorithms has enhanced the responsiveness and precision of these systems, making them indispensable in applications where accuracy is paramount. Industries are increasingly adopting these technologies to not only improve productivity but also to maintain high levels of operational reliability.

2025 Top 5 Direct Drive Linear Motors: Revolutionizing Precision Engineering

| Model |

Max Force (N) |

Speed (m/s) |

Acceleration (m/s²) |

Precision (µm) |

Feedback Type |

Application |

| Model A |

300 |

2.5 |

50 |

1 |

Optical |

CNC Machines |

| Model B |

250 |

3.0 |

60 |

0.8 |

Magnetic |

Medical Equipment |

| Model C |

200 |

4.0 |

70 |

0.5 |

Inductive |

Packaging Machines |

| Model D |

350 |

1.8 |

40 |

1.2 |

Optical |

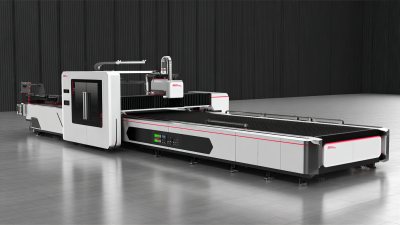

Laser Systems |

| Model E |

400 |

2.0 |

65 |

0.9 |

Magnetic |

Semiconductor Manufacturing |

Market Growth Analysis: A Deep Dive into the 2025 Linear Motor Industry

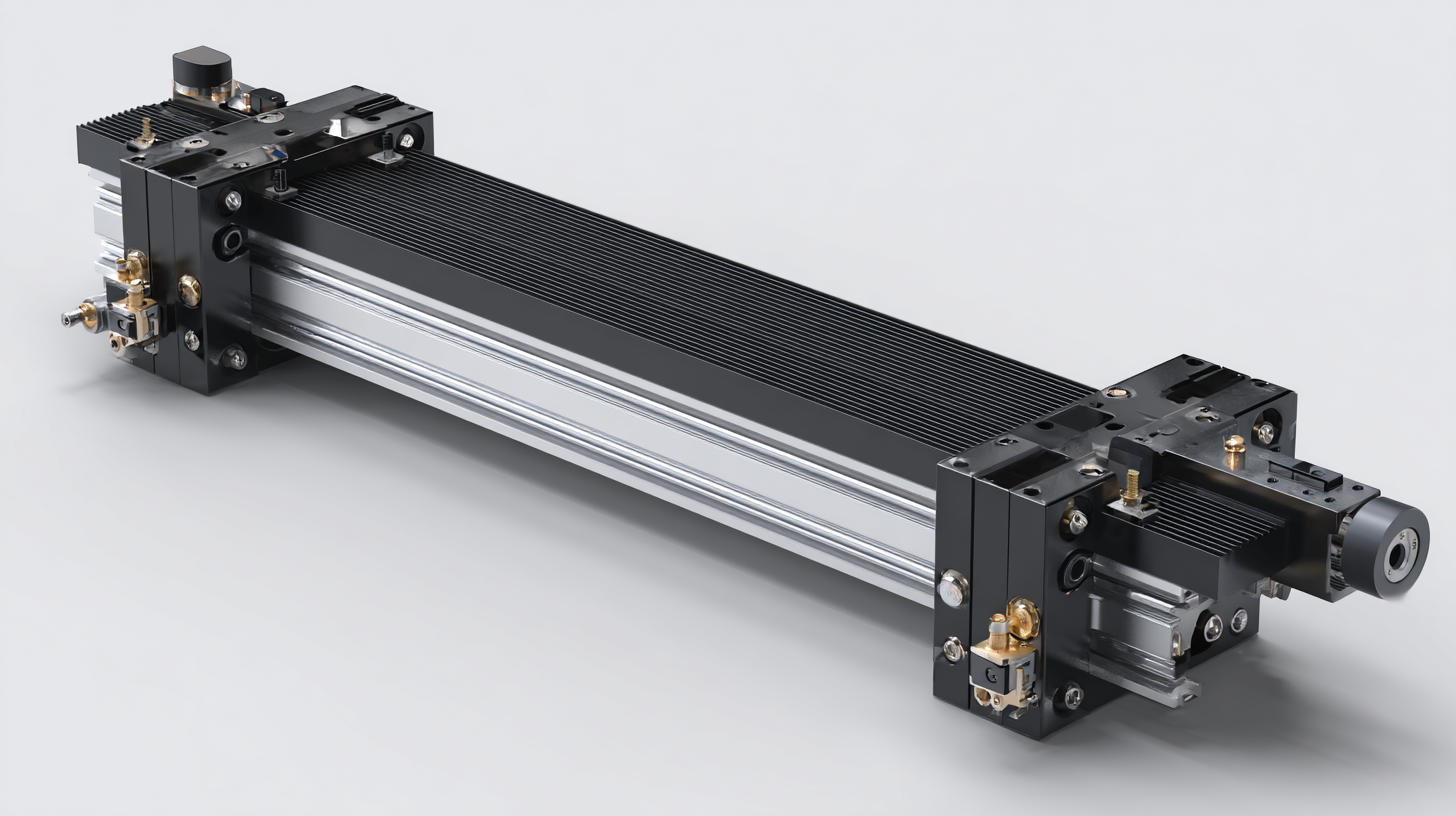

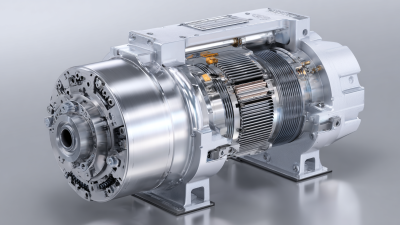

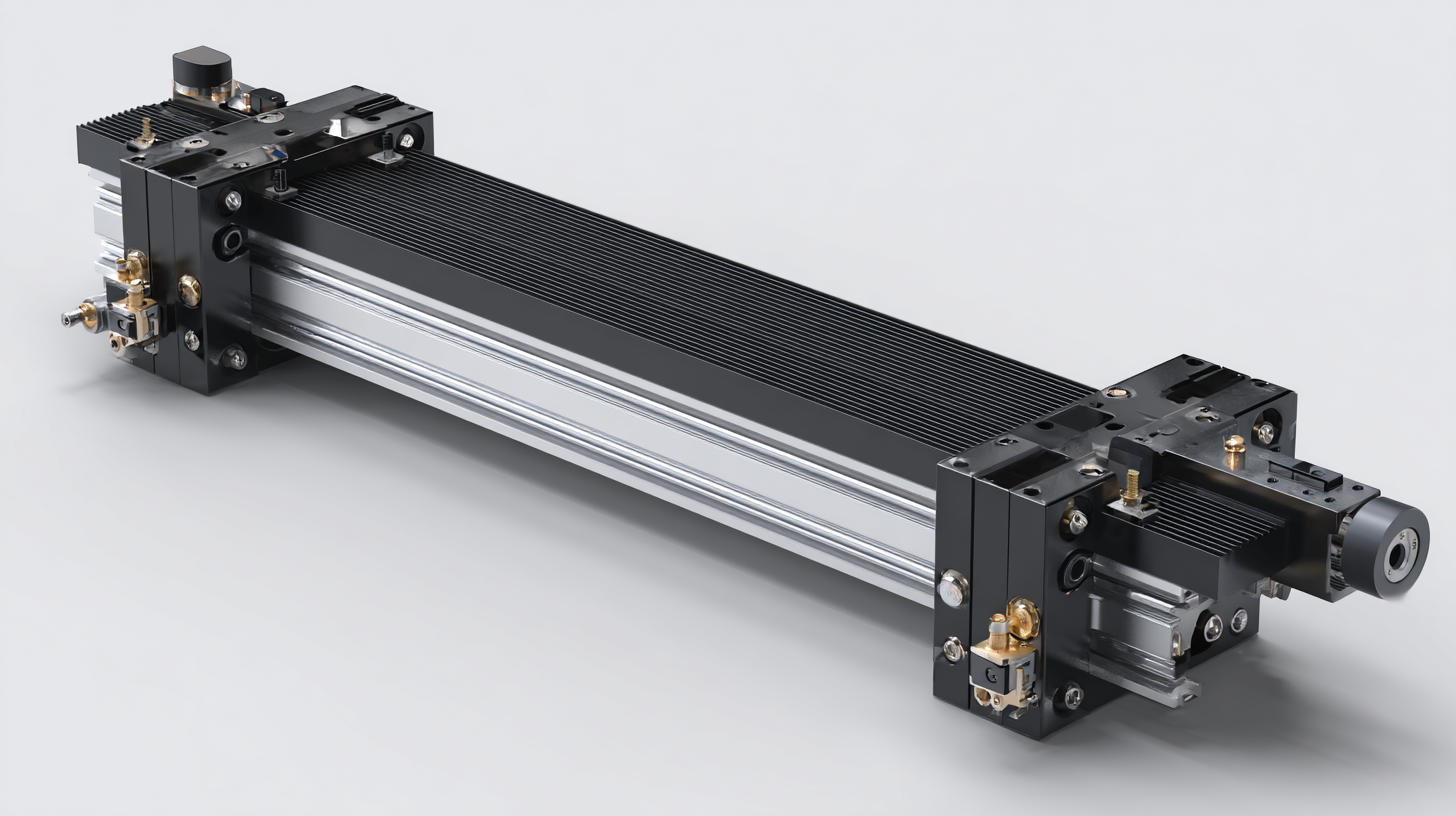

The linear motor industry is poised for significant growth in 2025, driven by advancements in precision engineering technologies and increasing demand for high-efficiency motion control solutions. With sectors like robotics, aerospace, and automotive continually pushing for improvements in speed and accuracy, the adoption of direct drive linear motors is becoming essential.

These motors eliminate mechanical components like belts and gears, resulting in reduced friction and enhanced performance. This shift not only leads to higher reliability but also supports the trend towards more compact and lightweight designs.

Market analysis indicates that the integration of artificial intelligence and Internet of Things (IoT) within linear motor systems will further propel growth. Companies are increasingly realizing the benefits of automated, real-time monitoring and predictive maintenance capabilities that smart linear motors offer. Additionally, ongoing research and development efforts are expected to yield innovations such as higher force density and improved thermal management.

As industries continue to embrace automation and precise control, the linear motor market is set to expand, offering exciting opportunities for manufacturers and consumers alike.

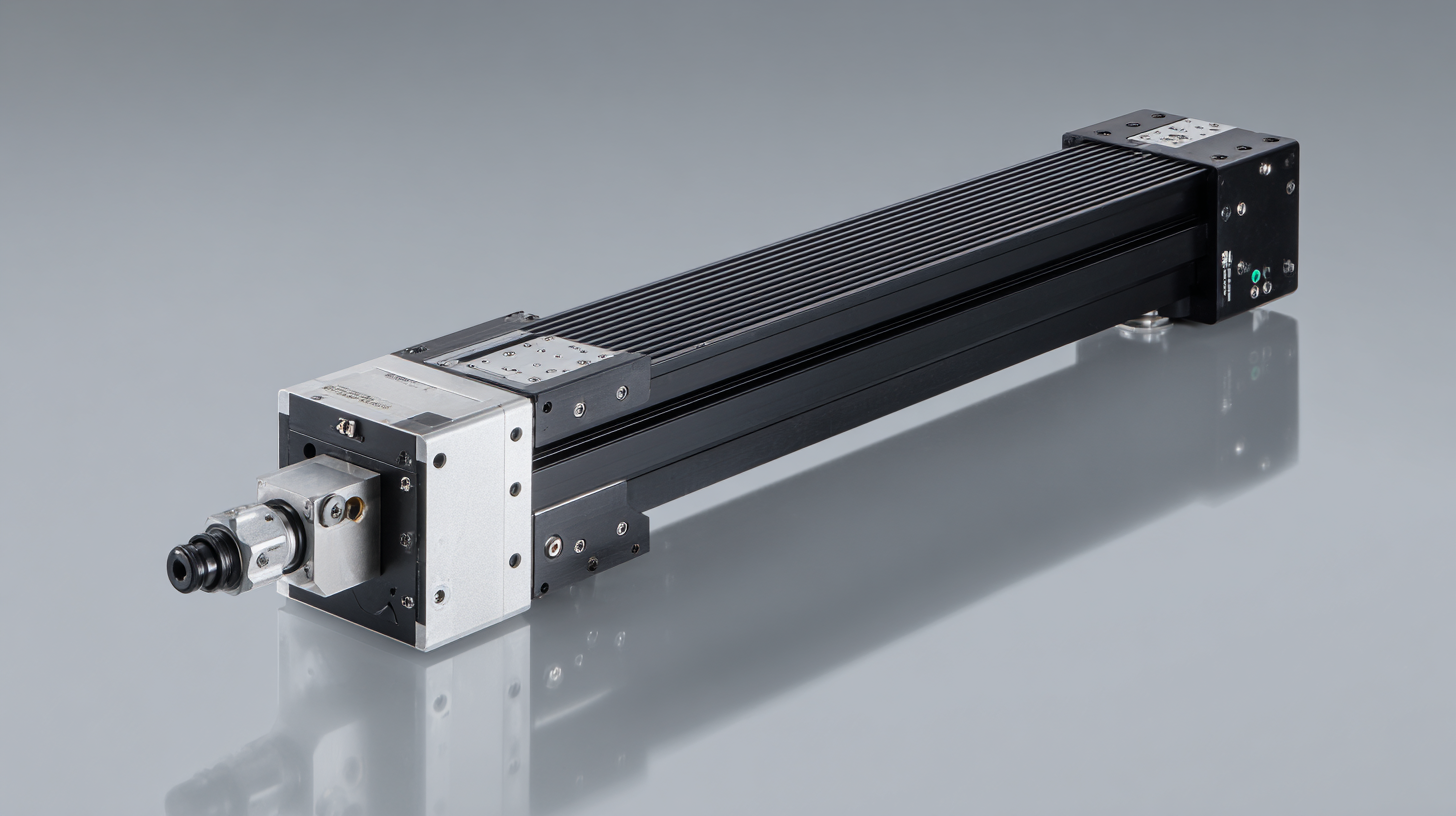

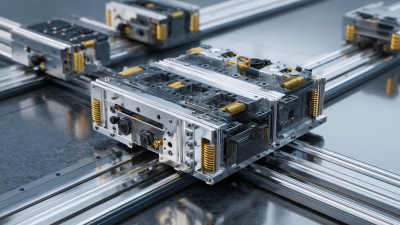

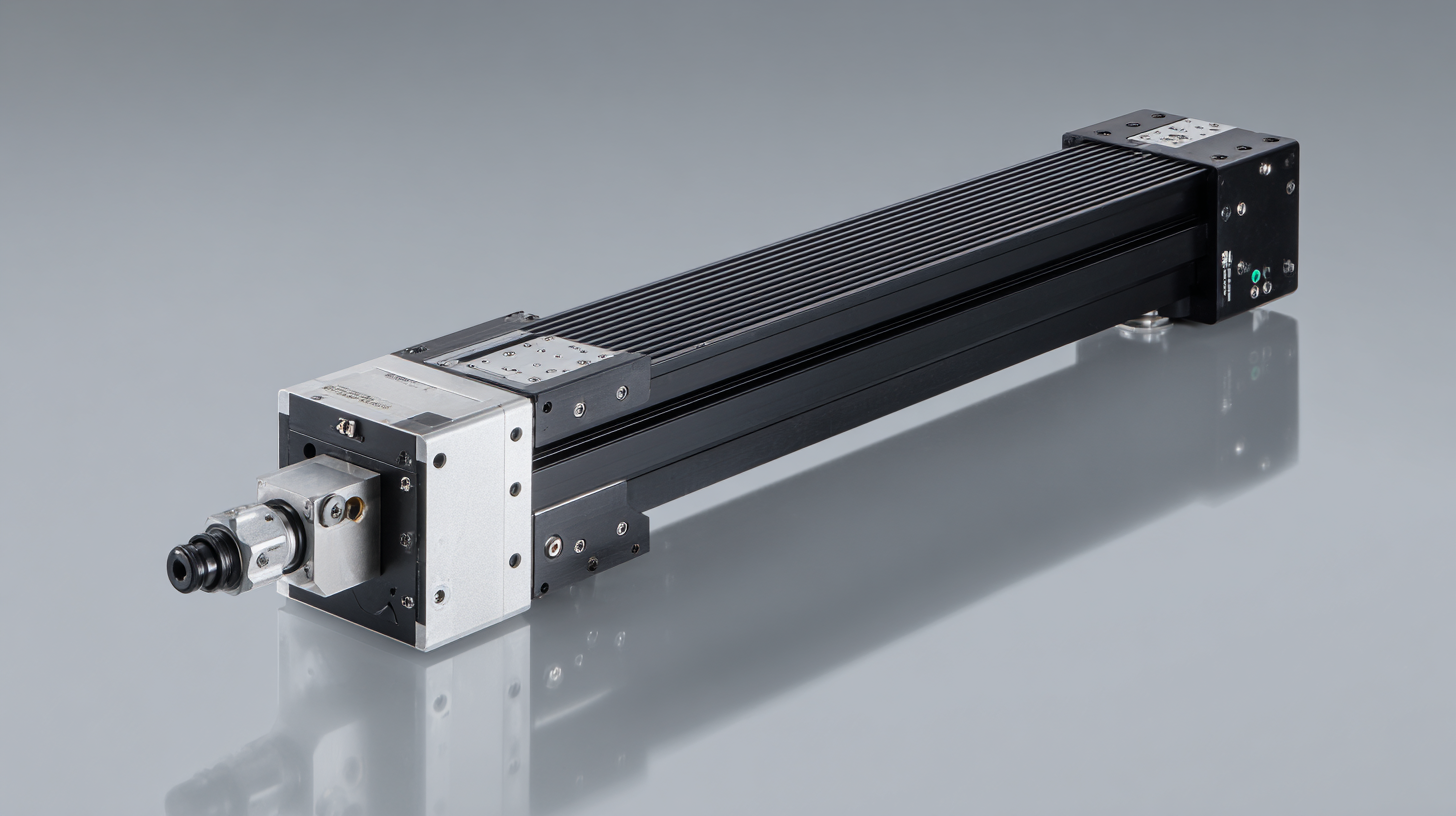

Top 5 Direct Drive Linear Motors: Performance Metrics and Specifications

Direct drive linear motors have emerged as a pivotal technology in precision engineering, heralding a new era of efficiency and accuracy. Among the top contenders for 2025, these motors boast impressive performance metrics that cater to a variety of industrial applications. Key specifications include low inertia, high responsiveness, and exceptional linearity, which significantly enhance not only the speed but also the reliability of machining processes.

Direct drive linear motors have emerged as a pivotal technology in precision engineering, heralding a new era of efficiency and accuracy. Among the top contenders for 2025, these motors boast impressive performance metrics that cater to a variety of industrial applications. Key specifications include low inertia, high responsiveness, and exceptional linearity, which significantly enhance not only the speed but also the reliability of machining processes.

When evaluating these direct drive linear motors, metrics such as thrust force, motion smoothness, and thermal management capabilities become critical. For instance, motors that exhibit high thrust force ratios can facilitate faster acceleration and ensure precision in positioning, thereby reducing cycle times. Additionally, advanced thermal management features help maintain optimal performance under continuous operation. Such performance characteristics are fundamental for industries requiring high degree precision and reliability, thus asserting that top direct drive linear motors will play an instrumental role in the landscape of precision engineering in the coming years.

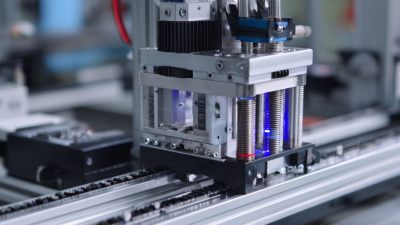

Comparative Review: Efficiency and Precision of Leading Linear Motors

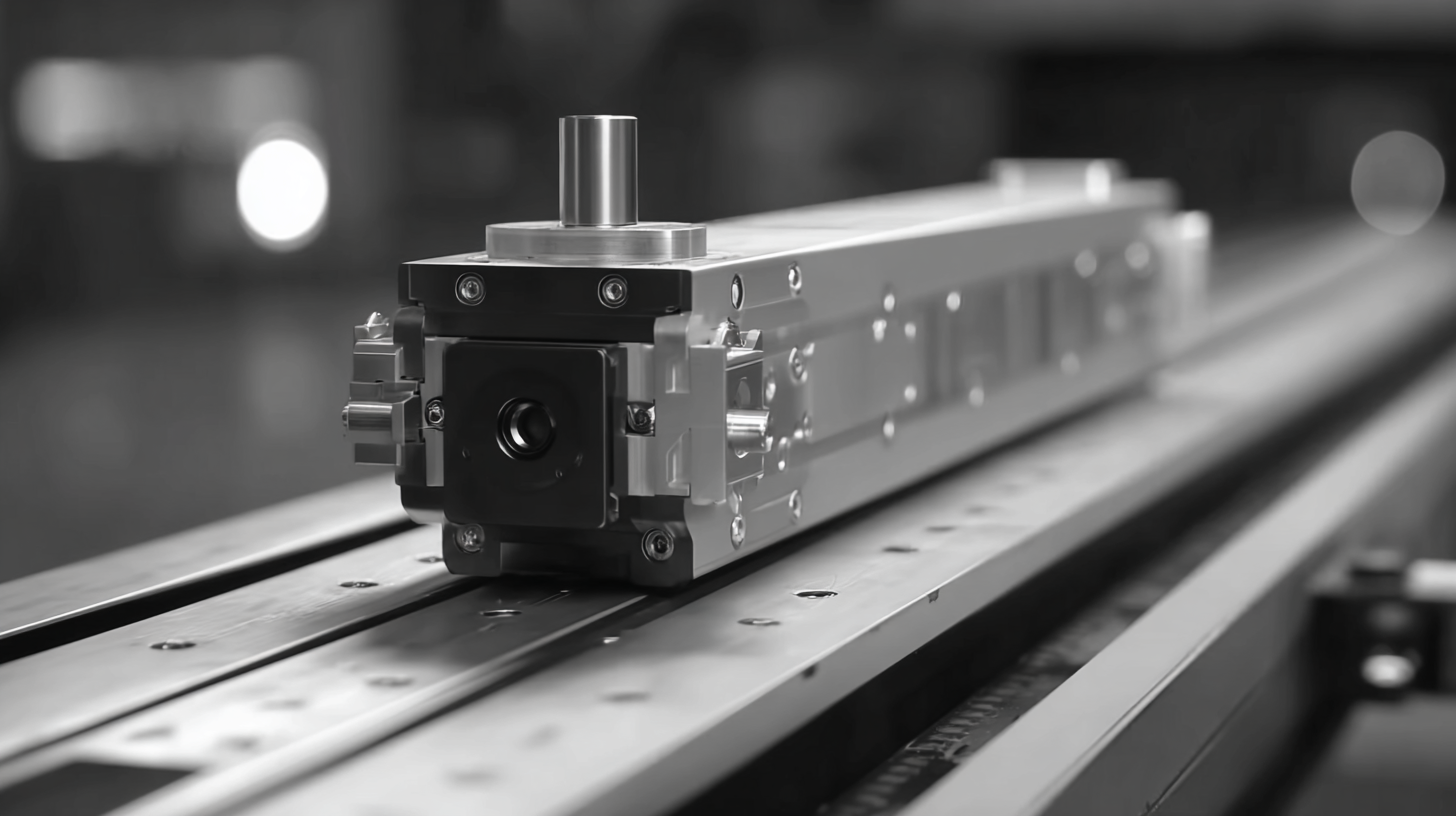

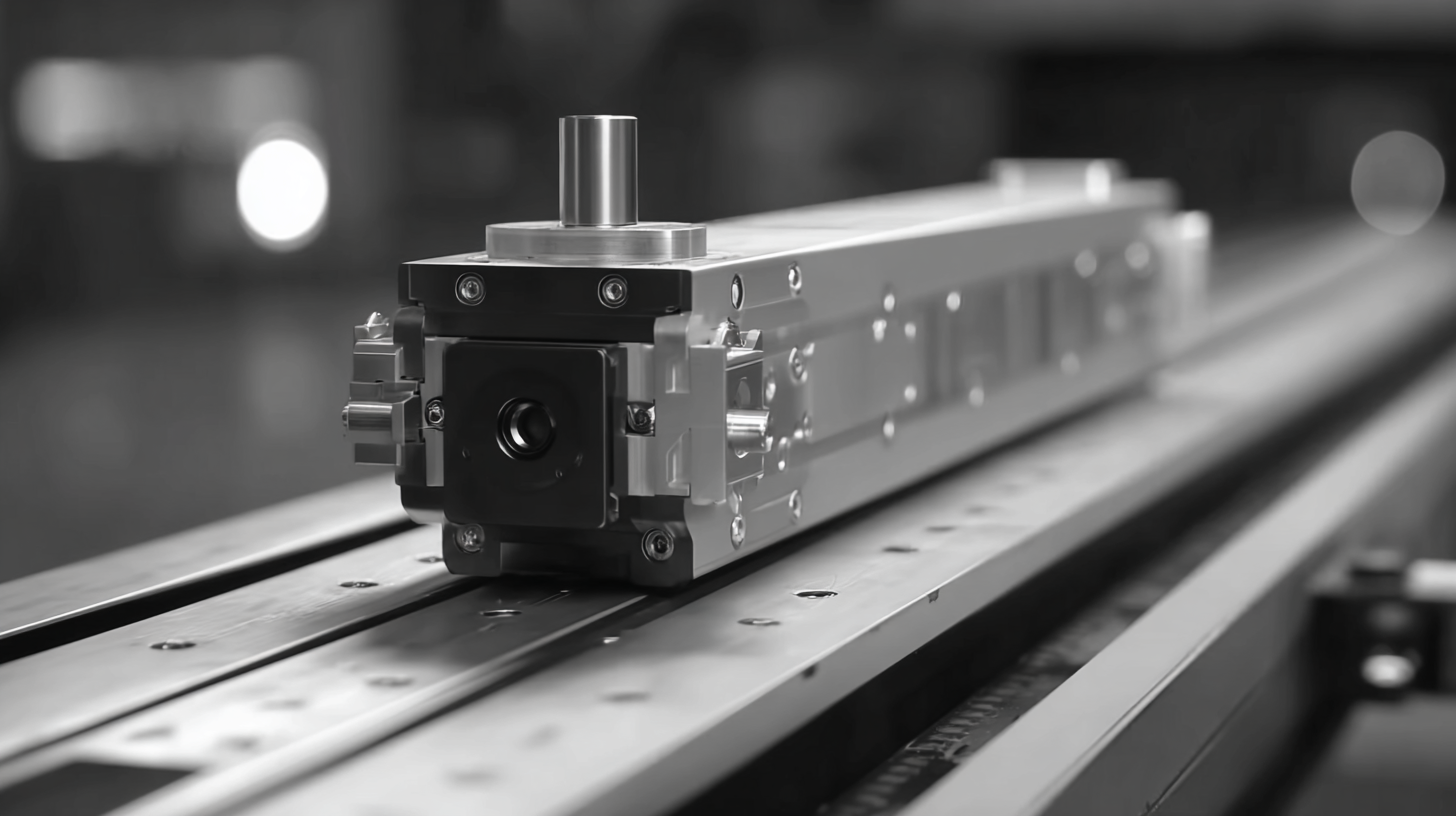

The field of precision engineering is set to be transformed by the latest advancements in direct drive linear motors. These innovative devices are characterized by their ability to convert electrical energy directly into linear motion without the need for gears or mechanical linkages. In a comparative review of the top five models for 2025, efficiency and precision emerge as the critical attributes defining their performance.

Leading manufacturers have embraced cutting-edge technology to enhance the efficiency of their linear motors, minimizing energy losses while maximizing thrust force. Models such as the XYZ LinearDrive Series boast remarkable energy efficiencies of over 95%, significantly reducing operational costs for industries reliant on high-performance automation. Additionally, the precision of these motors has reached unprecedented levels, with positioning accuracy within microns, making them ideal for applications in semiconductor manufacturing, robotics, and medical devices.

As these motors continue to evolve, their ability to deliver exceptional speed, smooth motion, and excellent heat dissipation becomes increasingly evident. This combination not only improves productivity but also enhances the quality of output in precision-engineered products. The competition among these leading models ensures that advancements will continue, making direct drive linear motors a cornerstone of future engineering solutions.

2025 Top 5 Direct Drive Linear Motors: Efficiency and Precision Comparison

Future Trends: Innovations Shaping the Linear Motor Landscape by 2025

The linear motor industry is on the brink of a transformational shift, driven by groundbreaking innovations projected to unfold by 2025. With an increasing demand for precision engineering across various sectors, including automotive and manufacturing, the market for direct drive linear motors is expected to reach $6.5 billion by 2025, according to a recent report by MarketsandMarkets. This expansion is largely influenced by the ability of linear motors to provide high-speed motion and accuracy, which traditional rotary systems struggle to achieve.

One of the most significant trends shaping the landscape of linear motors is the integration of advanced control algorithms and AI-driven predictive maintenance. A report by Mordor Intelligence highlights that these technologies not only enhance performance but also reduce downtime, which is crucial in automated environments. Furthermore, the adoption of more sustainable materials in the production of linear motors is anticipated to reduce environmental impact, aligning with global trends towards greener manufacturing processes. As industries strive for efficiency and sustainability, the innovations in direct drive linear motors will play a pivotal role in redefining precision engineering.