Ultimate Tips for Choosing the Best Home Laser Cutter Machine for Your Projects

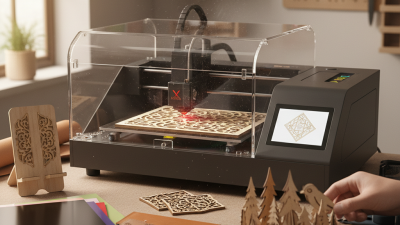

In recent years, the popularity of home laser cutter machines has surged, marking a significant transformation in the DIY and craft industries. According to a report by Research and Markets, the global laser cutting machine market is projected to grow at a CAGR of 6.5% from 2021 to 2026, with a notable shift towards compact and user-friendly models designed for home use. This growth reflects an increasing demand for precision cutting and engraving across various materials, ranging from wood to acrylic and leather, allowing hobbyists and small business owners to bring their creative visions to life.

As the technology becomes more accessible, it is essential for potential buyers to make informed decisions when selecting the best home laser cutter machine for their projects. Factors such as cutting area, power output, safety features, and software compatibility play critical roles in ensuring that the chosen machine meets specific project requirements. Additionally, understanding the intricacies of maintenance and support options available can greatly enhance the user experience, making it crucial to weigh these aspects carefully before making a purchase. By embracing expert guidelines and insights, users can navigate the myriad of options available in today’s market, ensuring they invest in a machine that not only fits their needs but also elevates their crafting capabilities.

Key Features to Consider in Home Laser Cutter Machines

When selecting a home laser cutter machine, several key features should be prioritized to ensure it meets your project requirements effectively. First, the cutting area is crucial; a larger workspace allows for more versatile projects. Consider the thickness and materials the machine can handle, as this will dictate the range of applications available, from wood to acrylic.

Additionally, check for adjustable settings that permit fine-tuning of power and speed, which can significantly enhance precision and result quality.

Another vital aspect to consider is the operating ease and software compatibility. Machines equipped with user-friendly interfaces and support for various design software can streamline your workflow, making the process smoother, especially for beginners. Safety features, such as emergency shut-off mechanisms and proper ventilation options, are also essential to ensure safe operation while working on intricate designs. Ultimately, evaluating these key attributes will guide you in selecting the most suitable laser cutter for your home projects, enabling creative possibilities without compromising on safety or functionality.

Types of Materials Compatible with Laser Cutters

When selecting a home laser cutter machine, understanding the types of materials it can work with is crucial for maximizing your projects' potential. Laser cutters are versatile tools that can handle a variety of materials, making them suitable for numerous applications. Common materials compatible with laser cutting include wood, acrylic, cardboard, and leather.

Wood is particularly popular due to its ease of cutting and engraving, allowing for intricate designs and professional finishes. Acrylic, on the other hand, produces striking results with smooth edges and vibrant colors, making it ideal for sign-making and decorative items.

In addition to these materials, laser cutters can also process metals like stainless steel and aluminum when paired with the right settings and equipment. This feature enables users to create custom parts and prototypes for practical applications. Other materials include paper and cloth, which can be effectively used for crafting and prototyping.

Understanding the compatibility of various materials will not only enhance your projects but will also help you choose a laser cutter that meets your specific needs. By focusing on the materials you'll be working with, you can ensure that your chosen machine operates efficiently and delivers the results you expect.

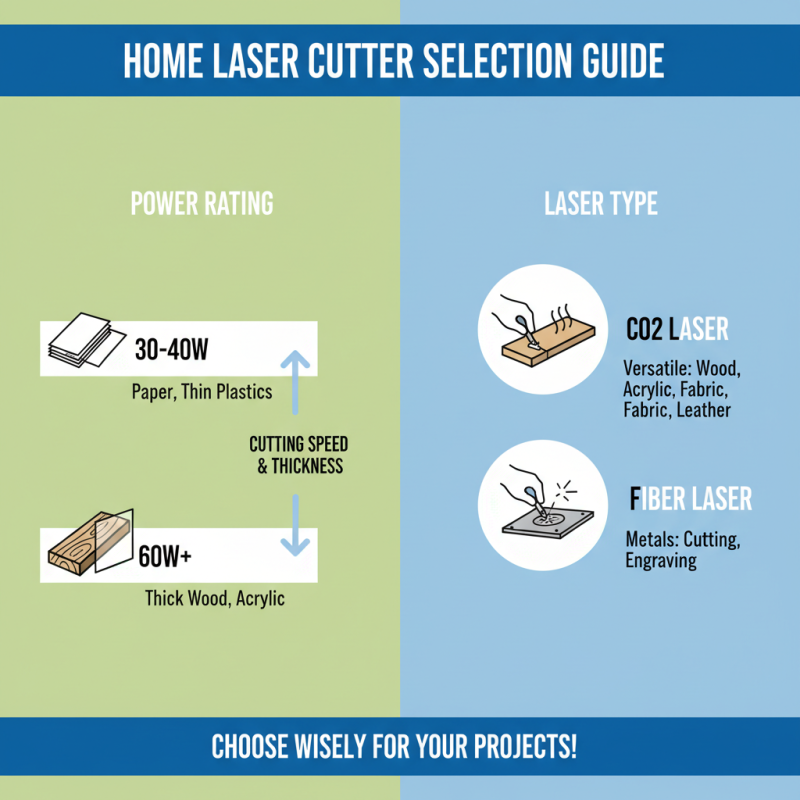

Understanding Laser Cutter Specifications and Power Ratings

When selecting a home laser cutter, understanding the specifications and power ratings is crucial. The power rating of a laser cutter, typically measured in watts, directly influences its cutting speed and the thickness of materials it can handle. For instance, lower wattage machines (around 30-40 watts) are suitable for lighter materials like paper and thin plastics, while higher wattage machines (60 watts or more) can cut through thicker wood and acrylic materials. Furthermore, the type of laser, whether CO2 or fiber, also plays a significant role in determining the applications you can achieve with the machine.

When evaluating a laser cutter, consider these tips: First, assess the maximum cutting thickness based on your project needs. If you're planning to work with a variety of materials, look for a machine that offers versatility in its cutting capabilities. Second, pay attention to the bed size. A larger bed can accommodate bigger projects, which is important if you intend to work on extensive designs or multiple items at once. Lastly, check the precision and engraving capabilities, as these aspects are essential for intricate designs that require accuracy.

By carefully considering these specifications and tips, you can choose a laser cutter that best suits your creative projects, ensuring you achieve optimal results every time.

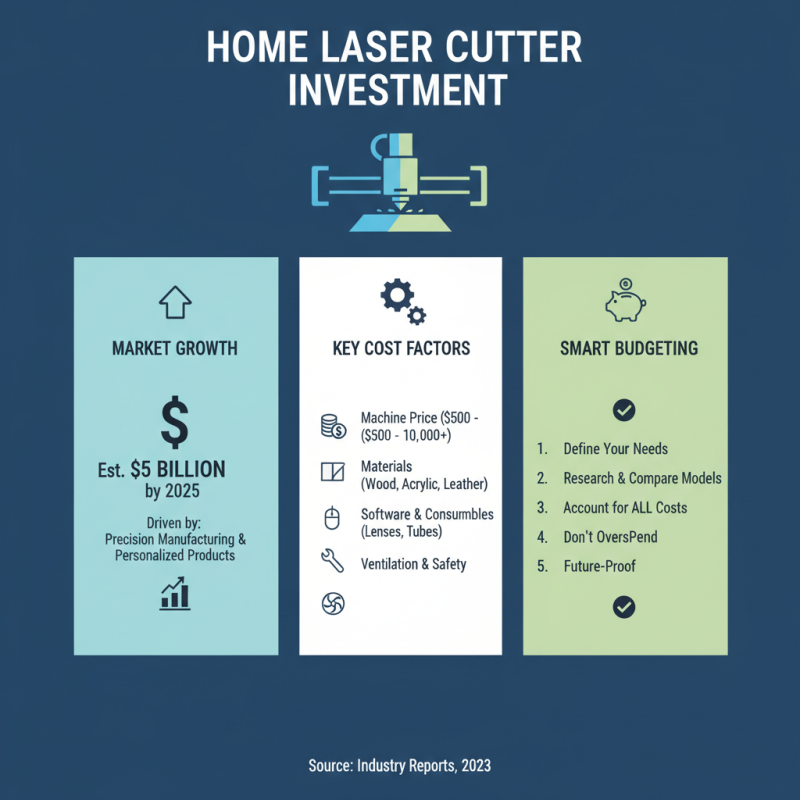

Budgeting for Your Home Laser Cutter Investment

When considering the investment in a home laser cutter, budgeting becomes a critical aspect of the decision-making process. According to industry reports, the market for laser cutting machines is projected to grow significantly, reaching an estimated value of $5 billion by 2025. This growth is driven by the increasing demand for precision manufacturing and personalized products. Understanding the costs associated with purchasing a laser cutter is essential to ensure you select a model that meets your needs without overspending.

The initial investment in a laser cutter can vary widely, with entry-level models priced around $200 and high-end commercial machines exceeding $10,000. It's vital to evaluate your project requirements and determine the features you need, such as cutting speed, material compatibility, and software capabilities. Regular maintenance and operating costs, including power consumption and consumables such as lenses and mirrors, should also factor into your budget. Data indicates that hobbyists and small business owners often overlook these ongoing expenses, which can lead to financial strain. Therefore, a comprehensive budgeting plan that accounts for both the purchase price and long-term operational costs will help ensure your investment is sustainable and supports your creative endeavors effectively.

Maintenance and Safety Tips for Home Laser Cutting Projects

When embarking on home laser cutting projects, maintenance and safety should be at the forefront of your considerations. Regular maintenance of your laser cutter not only extends its lifespan but also ensures optimal performance. Make it a habit to clean the lens and mirrors frequently, as residue can build up and affect the quality of your cuts. Additionally, check the alignment of the laser regularly; misalignment can lead to waste material and poor results.

Safety is paramount when operating a laser cutter. Always wear appropriate safety gear, including goggles specifically designed for laser work, to protect your eyes from potential hazards. It's also advisable to work in a well-ventilated area to mitigate the risks of fumes that may be released during the cutting process. Moreover, familiarize yourself with the machine’s safety features, such as emergency stop buttons, to ensure you can respond quickly in case of an emergency.

Before you start each project, ensure that all materials used are suitable for laser cutting. Some materials can produce toxic fumes when cut, so research beforehand and choose non-toxic options. Keeping your workspace organized will help prevent accidents and make the cutting process smoother. Implementing these tips will not only enhance the safety and efficiency of your home laser cutting projects but also provide peace of mind as you create.

Ultimate Tips for Choosing the Best Home Laser Cutter Machine for Your Projects - Maintenance and Safety Tips for Home Laser Cutting Projects

| Feature |

Description |

Importance Level |

Maintenance Tips |

Safety Tips |

| Power Output |

Determines cutting speed and material compatibility. |

High |

Regularly check and clean lenses. |

Always wear laser safety goggles. |

| Work Area Size |

Size of materials that can be used. |

Medium |

Keep the workspace organized and free of clutter. |

Ensure proper ventilation during operation. |

| Material Compatibility |

Types of materials that can be cut or engraved. |

High |

Test cutting on scrap materials first. |

Keep flammable materials away from the cutter. |

| Cooling System |

Prevents overheating during prolonged use. |

Medium |

Check coolant levels regularly. |

Have a fire extinguisher handy. |

| Software Compatibility |

Integration with design software for ease of use. |

High |

Update software regularly for improved features. |

Restrict access to the machine while in use. |