Top 10 Tips for Choosing the Best Steel Laser Cutting Machine

Choosing the right steel laser cutting machine can significantly impact production efficiency, cutting quality, and overall operational costs. According to industry expert Dr. Emily Johnson, a renowned specialist in advanced manufacturing technologies, "Selecting the appropriate steel laser cutting machine is not merely a purchase; it's an investment in the future capabilities of your production line." With the rapid advancements in laser technology, businesses often find themselves overwhelmed by the array of options available in the market.

A well-chosen steel laser cutting machine can enhance precision, reduce wastage, and increase throughput, making it essential to address key factors before making a decision. From evaluating power requirements and control systems to understanding maintenance needs and technology trends, prospective buyers must navigate several crucial considerations. In this article, we outline the top 10 tips to help you make an informed choice, ensuring that your investment aligns with your business's long-term goals. Embrace this opportunity to optimize your operations and stay ahead in an increasingly competitive landscape.

Understanding Your Steel Laser Cutting Needs

When selecting the best steel laser cutting machine for your business, a clear understanding of your specific cutting needs is essential. This involves assessing the types of steel materials you will be working with, such as mild steel, stainless steel, or aluminum, as well as the thickness and dimensions of these materials. Knowing these factors will guide you towards a laser cutting machine that can handle your projects efficiently and effectively.

One key tip is to consider the power and efficiency of the laser. Machines with higher wattage can cut through thicker materials at a faster speed, which means improved productivity. Additionally, research the cutting speed and the maximum table size to ensure that the machine can accommodate your largest projects without sacrificing precision.

Another critical aspect is the machine's software compatibility and usability. An intuitive interface can significantly reduce training time for staff and improve operational efficiency. Look for laser cutting machines that come with advanced software features, such as nesting functions and optimized cutting paths, which can further enhance material usage and minimize waste. By aligning your machine choice with your production needs and operational capabilities, you will make a more informed decision that supports your business growth.

Top 10 Tips for Choosing the Best Steel Laser Cutting Machine

| Tip No. |

Factor to Consider |

Description |

Importance Level |

| 1 |

Laser Power |

Select a machine with the right wattage for your cutting thickness needs. |

High |

| 2 |

Cutting Speed |

Consider the speed at which the machine operates for efficiency. |

Medium |

| 3 |

Bed Size |

Choose a bed size that fits your workpieces. |

High |

| 4 |

Material Compatibility |

Check which materials the machine can effectively cut. |

High |

| 5 |

Software Compatibility |

Ensure the machine integrates with your design software. |

Medium |

| 6 |

Maintenance Requirements |

Review how easy it is to maintain the equipment. |

Medium |

| 7 |

Energy Efficiency |

Select machines that consume less power for cost savings. |

Medium |

| 8 |

Support and Warranty |

Verify the support options and warranty terms offered. |

High |

| 9 |

Portability |

Consider the ease of moving the machine if needed. |

Low |

| 10 |

Budget |

Determine the price range that fits your financial capacities. |

High |

Key Factors to Consider in Laser Cutting Machines

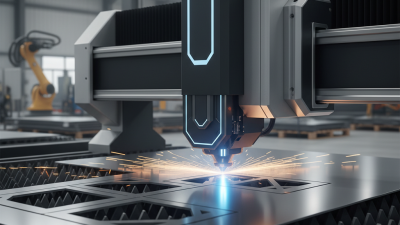

When selecting the best steel laser cutting machine, several key factors must be considered to ensure optimal efficiency and performance. First and foremost, the power of the laser is critical. According to a report by Industry Insights, machines with higher wattage can cut thicker materials at faster speeds, which is advantageous for heavy industrial applications. This means that choosing a machine with the right power level can significantly impact productivity and operational costs.

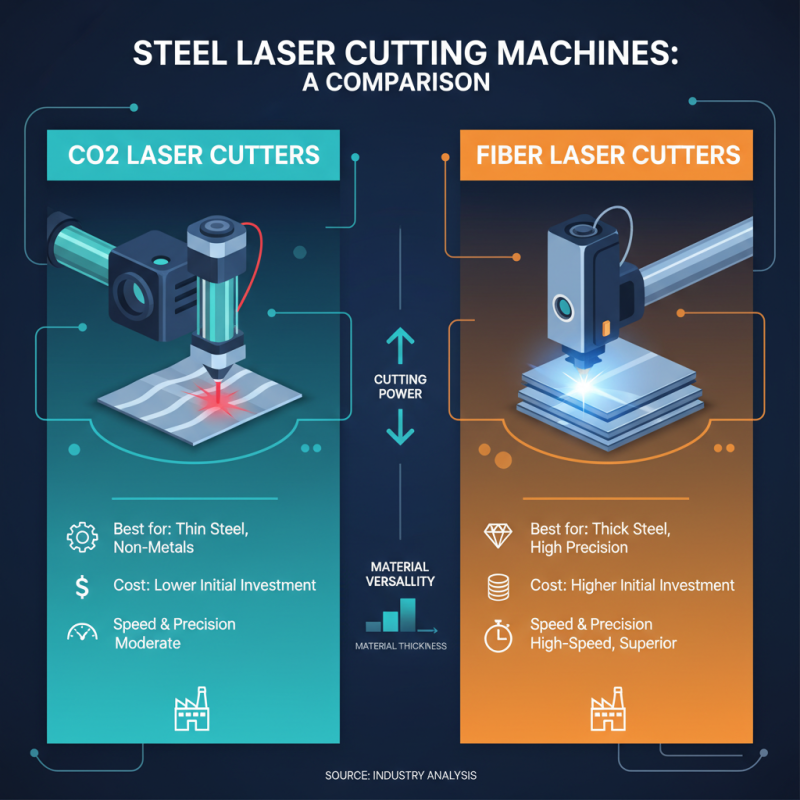

Another essential factor is the cutting technology employed by the machine.

CO2 lasers and fiber lasers are the two primary types used in steel cutting. While CO2 lasers have been common, fiber lasers are gaining popularity due to their efficiency and lower operational costs. Research from the Laser Institute of America indicates that fiber lasers are capable of providing superior cut quality on stainless steel while consuming up to 30% less energy than their CO2 counterparts.

Tip 1: Evaluate the machine's operational speed, as this will directly affect your throughput. Machines that can maintain high speeds while delivering precision cuts will enhance your overall productivity.

Tip 2: Consider the support and service offered by the manufacturer. A reliable support system ensures that any technical issues can be resolved quickly, minimizing downtime in your operations.

Assess industry reports and user reviews to gauge the long-term reliability and performance of the machines you consider, as this insight can guide you in making a well-informed decision.

Comparing Different Types of Steel Laser Cutters

When selecting a steel laser cutting machine, it’s essential to understand the differences between various types available in the market. The two primary categories are CO2 laser cutters and fiber laser cutters. CO2 lasers, favored for their effectiveness on non-metal materials, can also cut through thin sheets of steel. They are typically more affordable, making them a suitable choice for small to medium-sized operations. However, for industries focused on high-precision cutting of thicker materials, fiber lasers are often the preferred option due to their superior beam quality and cutting speed.

Another crucial distinction lies in the power output of the machines. While lower wattage machines are adequate for intricate designs and lighter materials, they may struggle with thicker steel profiles. On the other hand, high-power systems provide the capability to handle heavy-duty materials and thicker sheets, allowing for more versatile applications. Additionally, varying focal lengths influence the quality and precision of the cut, so understanding how these factors interplay is vital in making an informed choice. Ultimately, evaluating these types and their respective functionalities can lead you to the best-suited steel laser cutting machine for your specific needs.

Evaluating Machine Specs: Power, Speed, and Precision

When selecting a steel laser cutting machine, evaluating the specifications such as power, speed, and precision is crucial for ensuring optimal performance. The power of the laser, measured in watts, directly influences its cutting capabilities. Higher wattage typically translates to quicker material penetration and the ability to cut through thicker steel. Therefore, consider the thickness of the materials you will work with and choose a machine that provides sufficient power to handle your specific needs.

Speed is another vital aspect to consider. A machine with faster cutting speeds can improve production efficiency, allowing for more tasks to be completed in less time. However, it's essential to balance speed with precision. High-speed cutting can sometimes compromise the quality of the edges, which is why you should look for machines that offer adjustable speed settings. This flexibility enables you to optimize the performance based on the intricacy of the designs you are producing.

Moreover, precision is key in laser cutting, especially in applications that require tight tolerances. Look for machines that boast advanced focus control and motion systems. These features often result in cleaner cuts and finer details, minimizing the need for secondary finishing processes. Investing in a machine with excellent precision can lead to higher-quality outputs and reduced waste, offering significant advantages in the long run.

Assessing Maintenance and Support Services for Longevity

When selecting a steel laser cutting machine, it is crucial to consider the maintenance and support services that come with it. A reliable machine can only perform effectively with regular upkeep and timely assistance when problems arise. Investigate the manufacturer's maintenance schedules, as well as the availability of replacement parts. Robust maintenance services can greatly extend the lifespan of your equipment and help avoid costly downtimes. Look for manufacturers that provide comprehensive manuals and easy access to technical support.

Another essential factor is the availability of training and service personnel. Support services should ideally include both remote assistance and on-site visits from trained technicians. This not only enhances your team's familiarity with the machine but also ensures issues are resolved quickly, minimizing disruptions in your production process. Moreover, facilities that offer ongoing training sessions can help your workforce stay updated on best practices and new features, promoting efficient and effective use of your laser cutting machine over time.

Top 10 Tips for Choosing the Best Steel Laser Cutting Machine