Top Steel Laser Cutting Machine Features and Benefits Explained?

The steel laser cutting machine stands at the forefront of modern manufacturing. Its precision and speed revolutionize industries, enhancing productivity. With advanced features, these machines deliver exceptional accuracy in cutting various steel thicknesses. The automation they offer reduces human error, making production more reliable.

These machines are not without challenges, though. Operators must be well-trained to maximize their potential. Understanding the intricacies of operation is crucial. Investing in quality maintenance can prevent costly downtimes. Facilities must consider safety measures, as high-powered lasers present risks.

The benefits outweigh the concerns when used correctly. Efficiency in production can lower costs significantly. Businesses can adapt quickly to market demands. A steel laser cutting machine, therefore, is not just a piece of equipment; it’s an integral part of the manufacturing evolution.

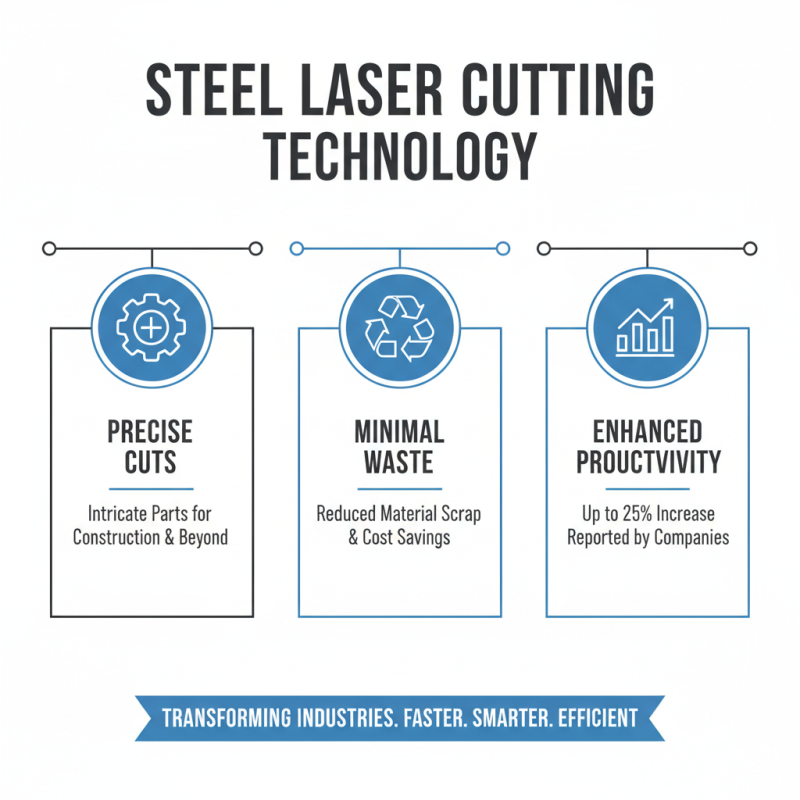

Key Features of Steel Laser Cutting Machines

Steel laser cutting machines have revolutionized the manufacturing sector. Their precision and efficiency stand out in an industry eager for productivity. According to recent market research, the global laser cutting machine market is expected to grow at a CAGR of over 7% from 2021 to 2026. This growth reflects the rising demand for precise and rapid cutting technologies.

Key features of these machines include high-speed processing and minimal material waste. Laser cutting can achieve thicknesses of up to 25 mm with intricate designs. The technology enhances material savings, which is critical in today’s cost-sensitive environment. However, achieving optimal results requires skilled operators. Users often underestimate the learning curve associated with machine programming and operation.

Safety features are paramount in steel laser cutting machines. Many come equipped with advanced laser safety systems. Yet, accidents can occur. Regular training and updates on safety protocols are essential. This need for ongoing education highlights a gap in the industry, as some facilities lack up-to-date training programs. To maximize their benefits, companies must address these shortcomings diligently.

Advantages of Laser Cutting Over Traditional Methods

Laser cutting technology offers several advantages over traditional cutting methods, particularly for steel fabrication. One major benefit is precision. Laser cutters can achieve intricate designs with tight tolerances. This allows for less material waste. Traditional methods often create more scrap metal, which can be costly and inefficient.

Speed is another noteworthy advantage. Laser cutting machines operate faster than manual cutting methods. They can cut through thick steel sheets within minutes. This increased efficiency translates to shorter production times. However, some users may find that initial setup takes longer than expected. Adjustments and calibrations can be tricky.

The versatility of laser cutters is impressive. They can handle various materials and thicknesses. This adaptability is a significant plus for businesses. Yet, it's essential to consider maintenance costs. High-powered lasers require regular servicing. Users should weigh these factors before choosing laser cutting as their primary method. Overall, the benefits often outweigh the challenges.

Applications of Steel Laser Cutting Technology in Various Industries

Steel laser cutting technology has transformed multiple industries. This method allows for precise cuts, minimal waste, and enhanced productivity. In construction, laser cutting is essential for creating intricate parts. Reports indicate that companies using this technology have seen productivity increases of up to 25%.

In the automotive industry, steel laser cutting is pivotal. It enables manufacturers to produce complex shapes quickly and accurately. Various reports highlight that the automotive sector benefits from reduced lead times and improved quality control. These factors can lead to a significant drop in operational costs.

However, the implementation of laser cutting requires skilled operators. The technology is evolving rapidly, and continuous training is essential. Some businesses struggle to keep their staff updated on the latest techniques. Additionally, initial investment costs can be a barrier. Despite these challenges, the benefits often outweigh the drawbacks, especially when considering long-term gains.

Maintenance Tips for Optimal Performance of Laser Cutting Machines

Proper maintenance is essential for optimal performance in laser cutting machines. According to a report by the International Society of Automation, laser cutting machines can experience efficiency losses of up to 30% without regular upkeep. Scheduled maintenance includes checking the optics and cleaning lens surfaces. Even minor contamination can lead to distorted cuts.

Monitoring coolant levels is critical. Insufficient cooling can cause overheating, which may damage components. A survey by the Metal Fabrication Alliance found that 45% of machine failures were linked to coolant-related issues. Operators should routinely inspect and replace coolant as needed, ensuring the system runs efficiently.

Finally, software updates play a crucial role. Outdated software can hinder machine performance and capabilities. Frequent updates can enhance functionality and improve cutting precision. Awareness of these maintenance tips is key to avoiding costly downtimes. Neglecting them can lead to prolonged delays and wasted resources.

Top Steel Laser Cutting Machine Features and Benefits Explained

| Feature |

Description |

Benefits |

| Precision Cutting |

Utilizes advanced laser technology for intricate cuts |

High accuracy and reduced material wastage |

| Speed |

High-speed operation for efficient production |

Increased output and faster turnaround times |

| Versatility |

Can cut various materials and thicknesses |

Adapts to different projects and requirements |

| Low Operating Costs |

Reduced energy consumption compared to traditional methods |

Lower expenses and higher profit margins |

| User-Friendly Interface |

Intuitive controls for easy operation |

Reduces training time and improves productivity |

Maintenance Tips for Optimal Performance of Laser Cutting Machines

| Maintenance Task |

Frequency |

Benefits |

| Lens Cleaning |

Daily |

Ensures optimal cutting quality and minimizes errors |

| Alignment Check |

Weekly |

Maintains precision and accuracy in cuts |

| Software Updates |

Monthly |

Incorporates improvements and new features |

| Cooling System Maintenance |

Quarterly |

Prevents overheating and extends machine lifespan |

| Inspection of Mechanical Components |

Annually |

Ensures overall operational safety and efficiency |

Future Trends in Steel Laser Cutting Technology

The future of steel laser cutting technology is bright and exciting. Innovations are shaping the industry in unexpected ways. One key trend is automation. Machines are getting smarter, reducing the need for constant human oversight. This advancement allows faster production speeds and consistent quality.

Another trend is the integration of artificial intelligence. AI systems can now optimize cutting paths and reduce waste. This not only saves materials but also enhances efficiency. Plus, predictive maintenance is becoming more common. Machines can alert operators about potential issues before they arise. This limits downtime and boosts productivity.

Sustainability is also gaining traction. Companies are investing in eco-friendly technologies. There’s a push for energy-efficient systems that minimize carbon footprints. However, challenges still exist. Not all companies can afford such upgrades. Balancing innovation with practicality is crucial. The journey ahead is filled with opportunities and obstacles.

Top Steel Laser Cutting Machine Features and Benefits Explained