Unlocking the Future of Automation: How Linear Motor Drives Revolutionize Industry Efficiency

The advent of automation technologies has significantly transformed industry efficiency, with linear motor drives taking center stage in this revolution. According to a report by MarketsandMarkets, the linear motor drive market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 8.5% from 2020. This surge is driven by the increasing demand for precision and speed in manufacturing processes across various sectors, including automotive and electronics.

Linear motor drives offer exceptional advantages, such as reduced maintenance costs, higher acceleration rates, and increased energy efficiency. As industries strive to enhance productivity while minimizing downtime, linear motor drives not only offer a solution but also redefine the standards of operational excellence. In this era of rapid technological advancement, unlocking the potential of linear motor drives is crucial for organizations aiming to stay competitive in an ever-evolving landscape.

The advent of automation technologies has significantly transformed industry efficiency, with linear motor drives taking center stage in this revolution. According to a report by MarketsandMarkets, the linear motor drive market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 8.5% from 2020. This surge is driven by the increasing demand for precision and speed in manufacturing processes across various sectors, including automotive and electronics.

Linear motor drives offer exceptional advantages, such as reduced maintenance costs, higher acceleration rates, and increased energy efficiency. As industries strive to enhance productivity while minimizing downtime, linear motor drives not only offer a solution but also redefine the standards of operational excellence. In this era of rapid technological advancement, unlocking the potential of linear motor drives is crucial for organizations aiming to stay competitive in an ever-evolving landscape.

The Evolution of Linear Motor Drives in Automation Technology

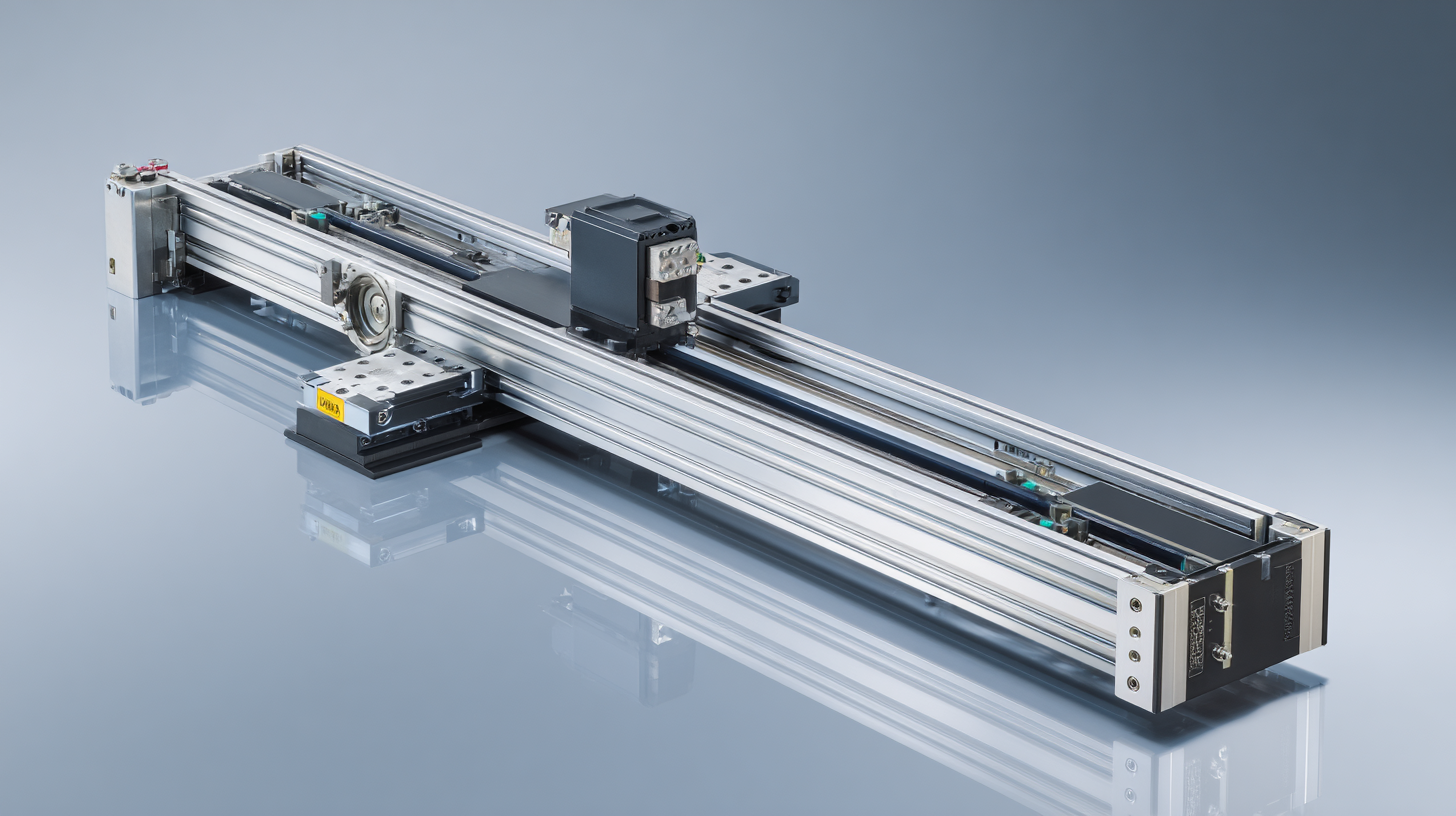

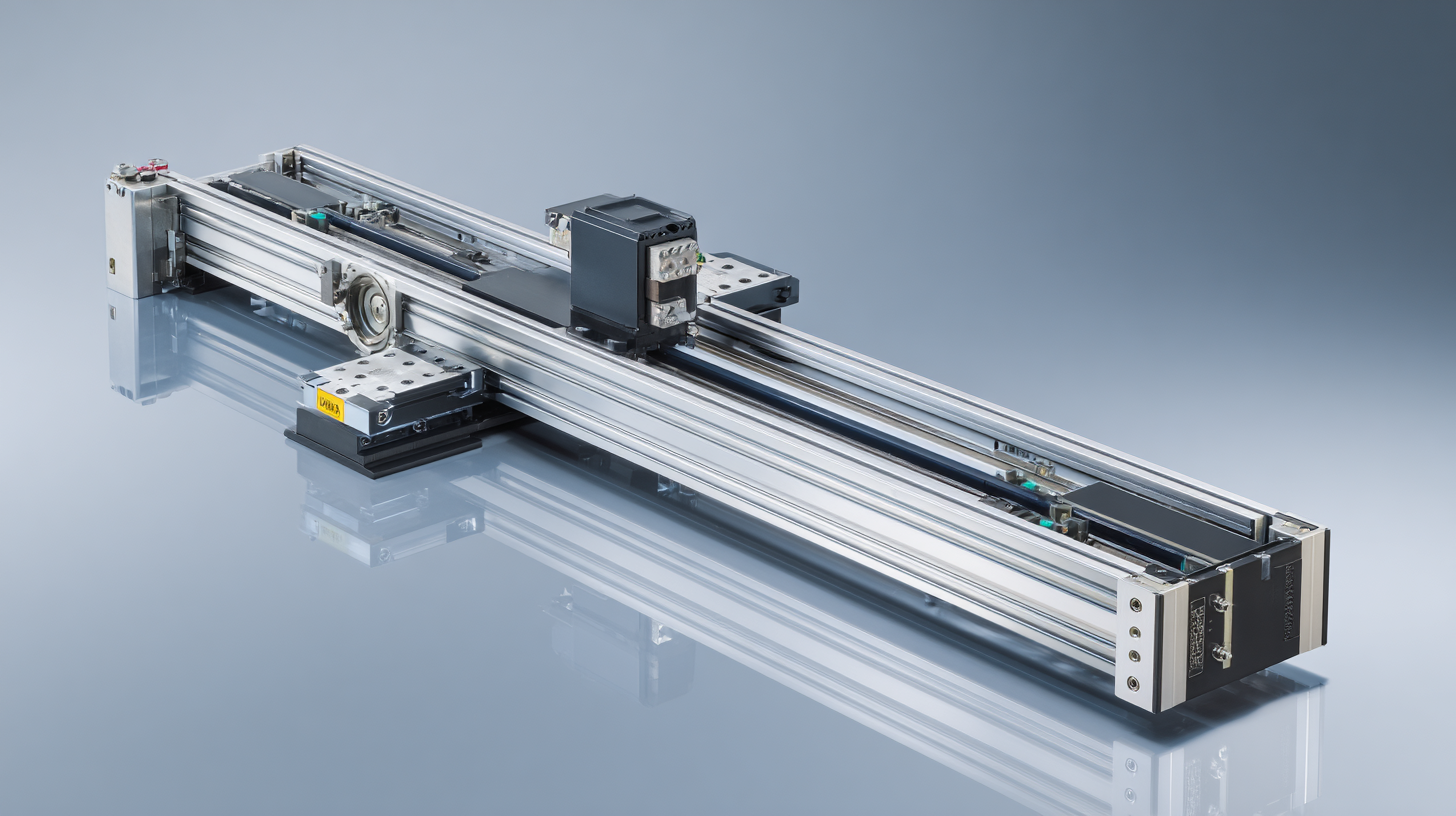

The evolution of linear motor drives has significantly transformed automation technology, enhancing efficiency across various industries. According to a recent report by McKinsey, the adoption of linear motor drives in manufacturing processes has enabled a reduction in cycle times by up to 30%. This improvement stems from the direct drive capability of linear motors, which eliminates the complexities of traditional rotary systems, thus facilitating faster and more precise movement of machinery components.

Additionally, a study published by Research and Markets highlights that the global linear motor market is projected to grow at a CAGR of 10.3% through 2025. This rapid growth is driven by the increasing need for automation in sectors such as automotive, electronics, and packaging, where precision and speed are critical. As industries seek to streamline operations, linear motor drives are proving to be vital in achieving sustainable production practices and optimizing the overall manufacturing workflow. Their ability to operate with minimal maintenance also offers significant cost savings, further solidifying their role in the future of automation technology.

Key Advantages of Linear Motor Drives Over Traditional Drive Systems

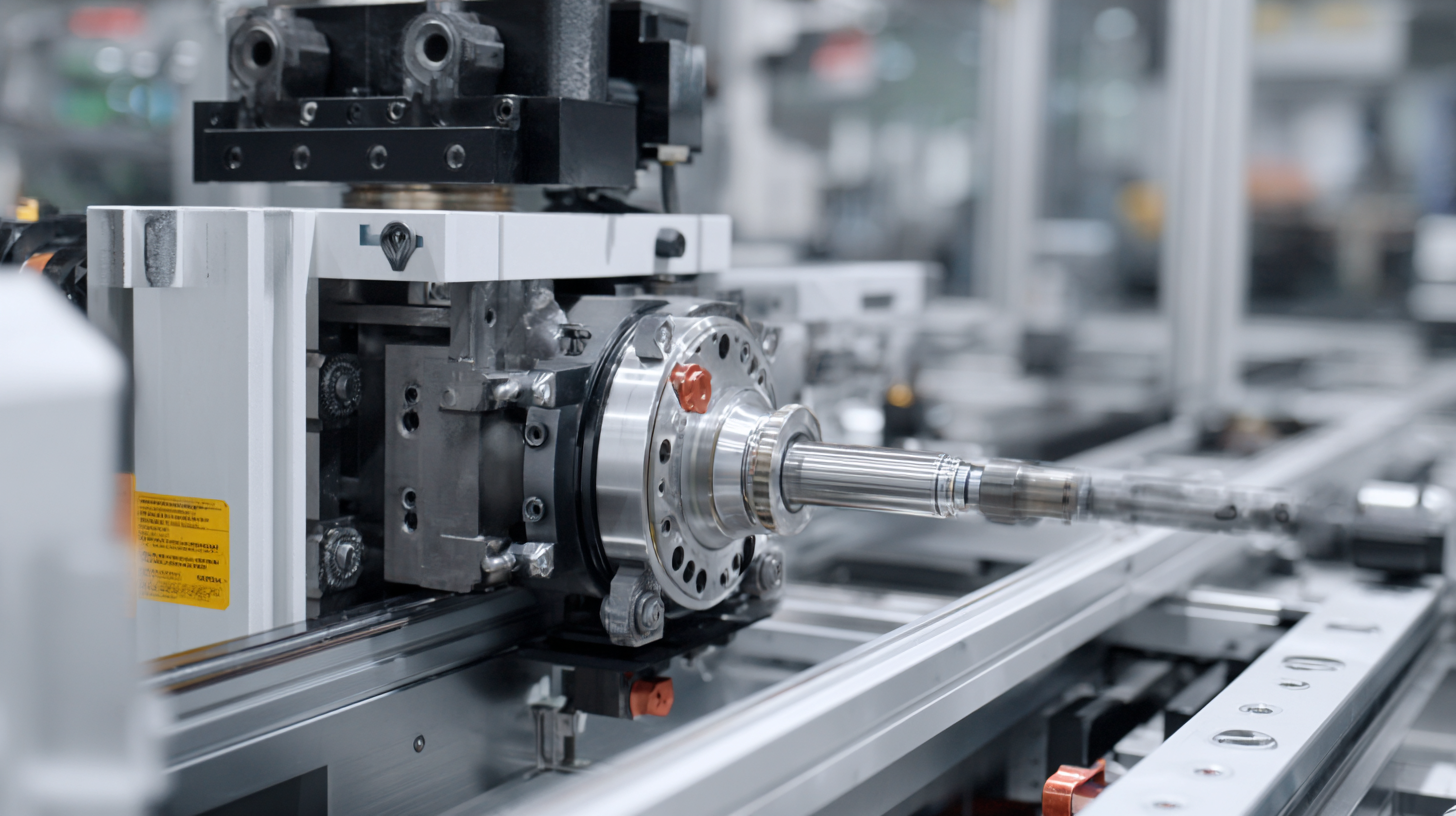

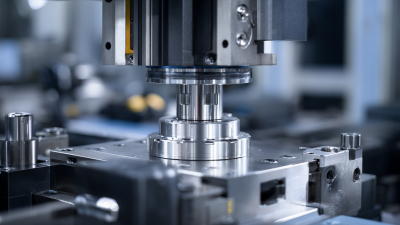

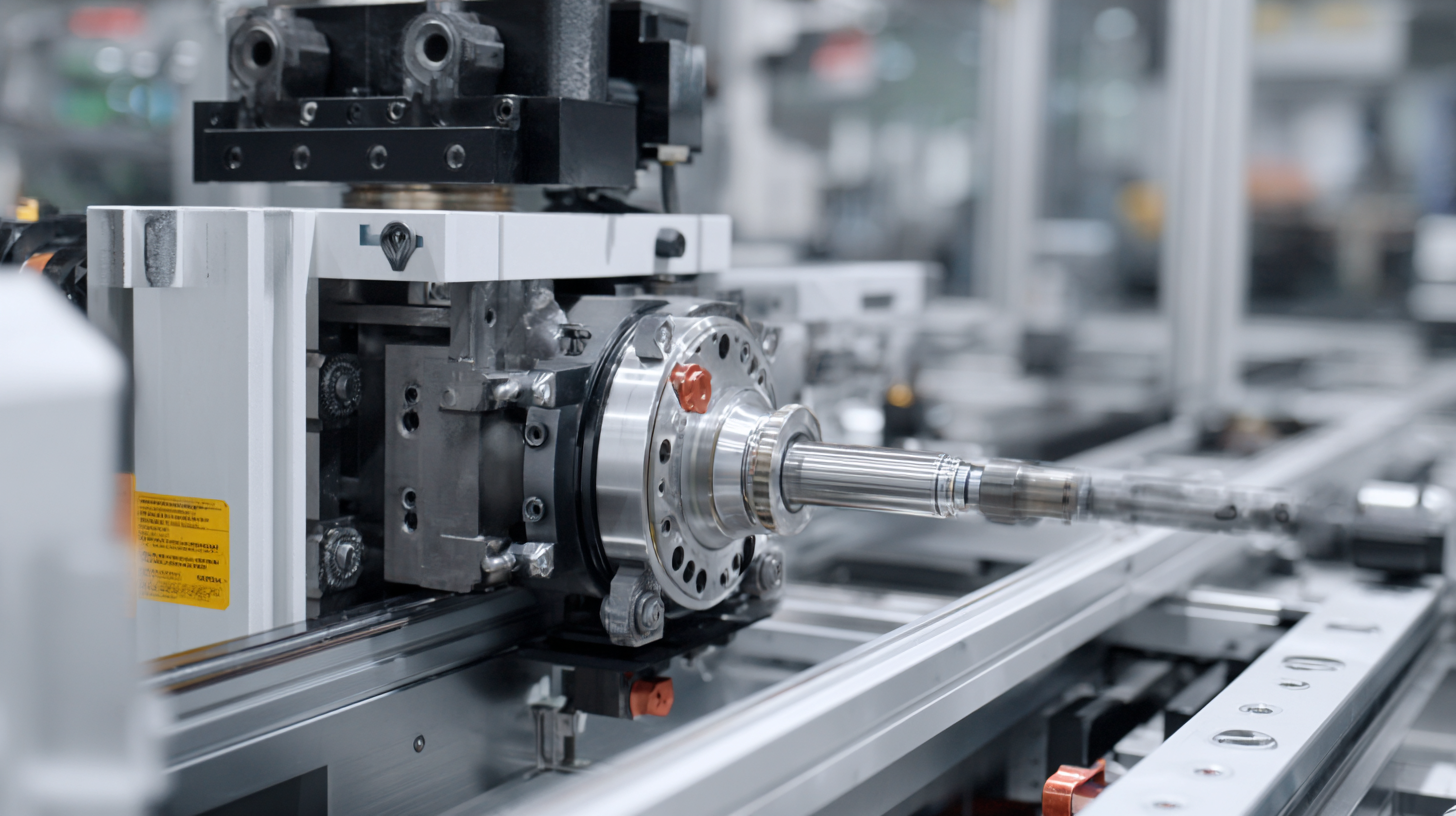

The advantages of linear motor drives over traditional drive systems are becoming increasingly pronounced in various industries. One of the most notable benefits is the high precision and speed that linear motors offer. Recent advancements indicate that linear motors can achieve accuracies up to ±1 μm over a distance of 100 mm, making them ideal for applications requiring meticulous control, such as in nanopositioning devices that can perform movements in increments as small as one nanometer. This capability opens new avenues in sectors including aerospace and defense, where precise positioning is critical.

Moreover, the elimination of mechanical components in linear motor drives results in reduced maintenance and increased reliability. As reported, traditional hydraulic and pneumatic systems have dominated in certain sectors; however, the increasing shift towards electrical actuators is transforming industry standards. The high efficiency and performance of linear motors, particularly in multi-field coupling systems that integrate electromagnetic-thermal-flow dynamics, support this transition. These innovations not only enhance operational effectiveness but also ensure that industries can meet the escalating demands for automation and precision in today's fast-paced production environments.

Applications of Linear Motor Drives Across Various Industries

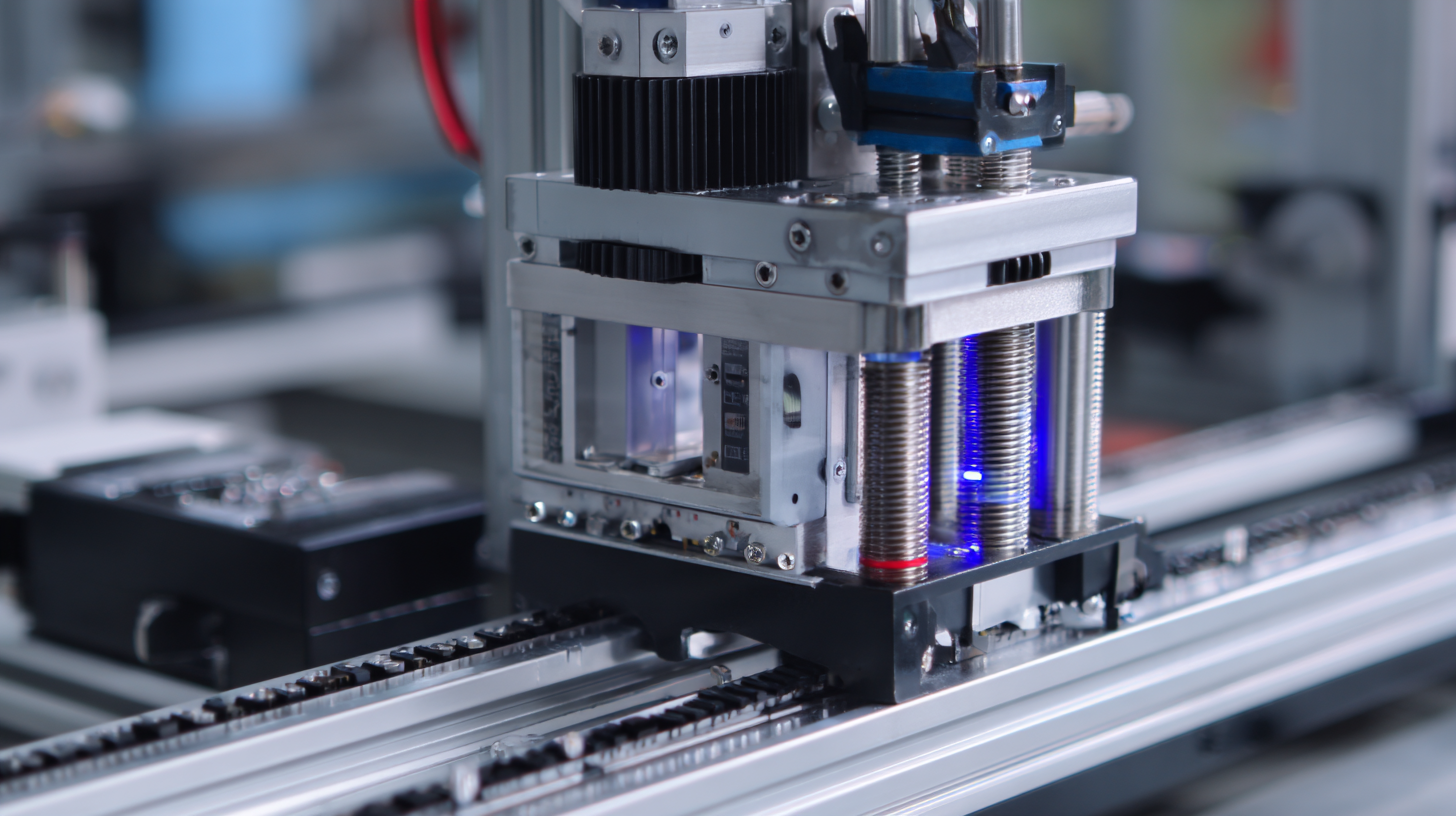

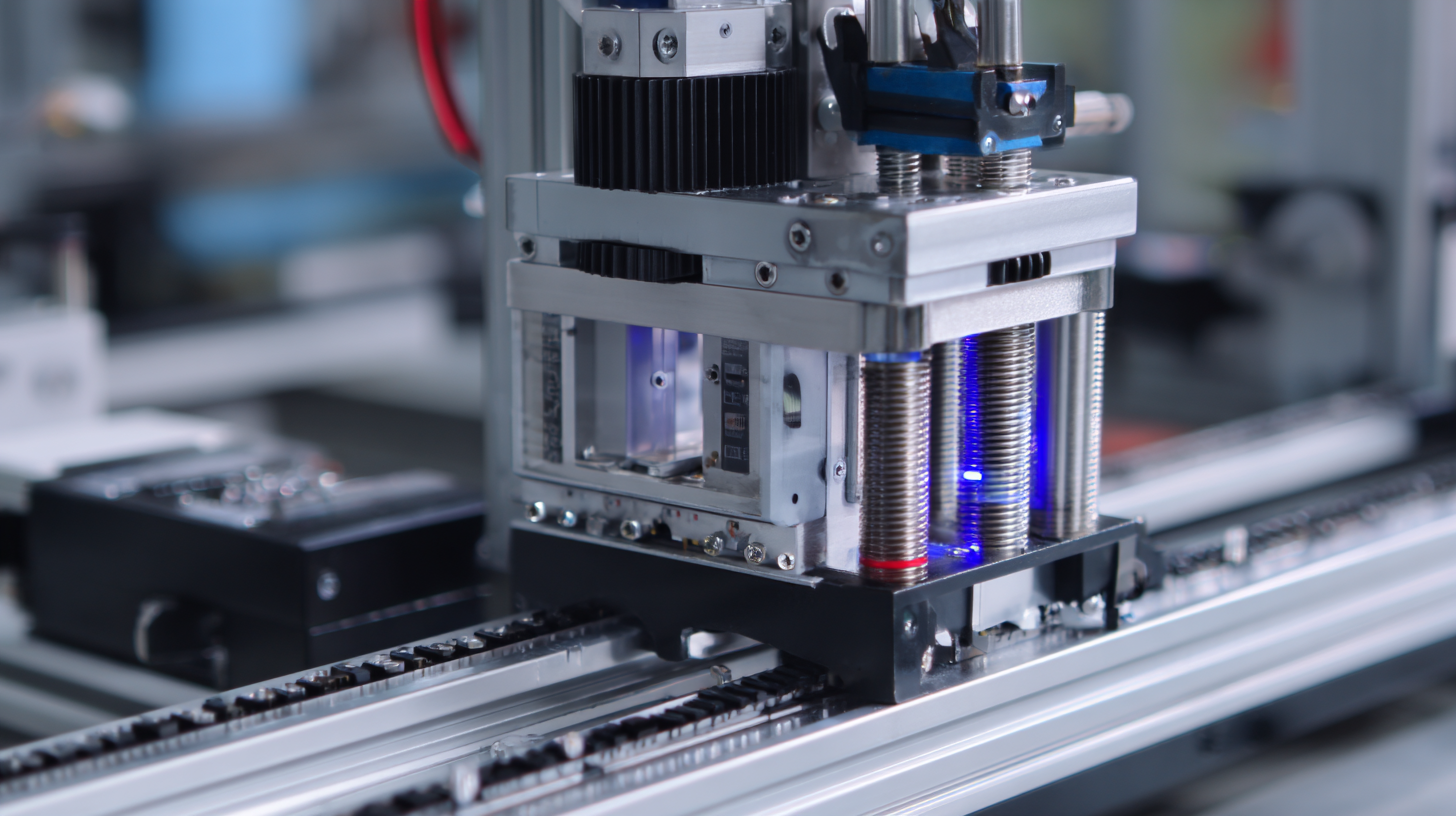

Linear motor drives are transforming multiple industries by enhancing precision, speed, and efficiency in automation. With advancements such as frictionless 3-phase linear motors, we see significant improvements in linear positioning systems. For instance, the introduction of high-precision linear positioning stages enables seamless integration into various applications, from robotics to manufacturing, showcasing the versatility of linear motor technologies.

Additionally, the growing trend of electrification across sectors further emphasizes the importance of linear motor drives. As industries adopt more advanced electronics and innovative battery technologies, the demand for efficient drive systems is increasing. High-voltage applications are also benefiting from direct drive linear motors, which deliver substantial performance while simplifying the design process for machine builders.

Tip: When selecting a linear motor drive for your application, consider factors like load requirements and precision levels to ensure you choose a system that enhances operational efficiency.

Incorporating these advanced technologies can propel your processes forward, making automation not only more effective but also more sustainable. Tip: Regularly evaluate the latest developments in linear motor technology to stay ahead in efficiency and performance in your industry.

Impact of Linear Motor Drives on Energy Efficiency and Sustainability

The integration of linear motor drives into industrial applications significantly enhances energy efficiency and fosters sustainable practices. A recent study on multi-motor systems emphasizes the potential of innovative inverter topologies to optimize energy use, demonstrating a marked reduction in energy consumption across various sectors. With the global market for stators and rotors in high-speed motors projected to grow from USD 3.2 billion in 2024 to USD 5.8 billion by 2030, the shift towards energy-efficient linear motors becomes increasingly critical in meeting both economic and environmental goals.

Moreover, advancements in electric motor technology, particularly brushless micro electric motors, illustrate their pivotal role in the transition to smarter, energy-efficient systems. These motors, characterized by their compact size and high efficiency, are being increasingly embraced in applications ranging from robotics to advanced manufacturing. The adoption of lean methodologies in manufacturing further supports this shift, as evidenced by studies indicating that lean tools can drive down energy consumption significantly. As industries seek to balance performance with sustainability, the impact of linear motor drives cannot be underestimated, positioning them at the forefront of future technological advancements.

Unlocking the Future of Automation: How Linear Motor Drives Revolutionize Industry Efficiency

| Key Metric |

Description |

Impact |

| Energy Efficiency Improvement |

Percentage reduction in energy consumption when switching to linear motor drives |

Up to 30% reduction |

| Operating Lifetime |

Average lifespan of linear motor drives compared to traditional systems |

Over 10 years longer |

| Maintenance Costs |

Reduction in maintenance frequency and costs |

Decreased by 50% |

| Noise Levels |

Comparison of noise reduction with linear motor drives |

Reduced by 15 dB |

| Carbon Footprint Reduction |

Decrease in CO2 emissions associated with operations |

Estimated 20% lower |

| System Responsiveness |

Time taken for linear motor drives to respond to commands |

Reduced to milliseconds |

Future Trends in Linear Motor Drive Technology and Industry Integration

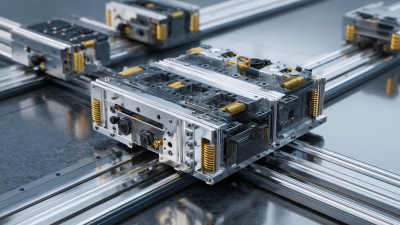

Linear motor drives are paving the way for advanced automation in various industries, significantly enhancing operational efficiency. As technology continues to evolve, several trends are emerging that promise to further integrate linear motor drive systems into industrial applications. One major trend is the rise of Industry 4.0, where smart factories leverage IoT and AI technologies. This integration allows for real-time monitoring and predictive maintenance, ensuring that linear motor drives can operate at peak performance.

**Tip:** When considering the adoption of linear motor drives, invest in training your workforce. Understanding the intricacies of this technology enables employees to maximize its potential, leading to enhanced productivity.

Another critical trend is the customization of linear motor drives for specific applications. As businesses increasingly demand tailored solutions, manufacturers are focusing on modular designs that allow easy scalability and adaptability. This flexibility helps companies to respond swiftly to market changes and improves overall system reliability.

**Tip:** Keep abreast of the latest advancements in linear motor technology to ensure that your systems remain competitive. Regularly evaluate equipment and consider upgrades that align with industry innovations.

Unlocking the Future of Automation: Efficiency Gains with Linear Motor Drives

The advent of automation technologies has significantly transformed industry efficiency, with linear motor drives taking center stage in this revolution. According to a report by MarketsandMarkets, the linear motor drive market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 8.5% from 2020. This surge is driven by the increasing demand for precision and speed in manufacturing processes across various sectors, including automotive and electronics.

The advent of automation technologies has significantly transformed industry efficiency, with linear motor drives taking center stage in this revolution. According to a report by MarketsandMarkets, the linear motor drive market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 8.5% from 2020. This surge is driven by the increasing demand for precision and speed in manufacturing processes across various sectors, including automotive and electronics.