Why Is Linear Motor Drive Transforming Modern Motion Technology?

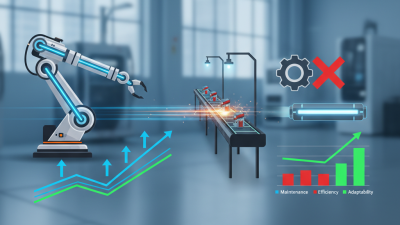

The transformation of modern motion technology is significantly driven by linear motor drives. These systems offer high precision and high-speed operation, essential in industries like robotics and manufacturing. According to a report by MarketsandMarkets, the linear motor drive market is projected to reach $2.85 billion by 2027, reflecting robust growth.

Expert Dr. Andrew Reynolds highlights, "Linear motors redefine the benchmarks for performance in automation." This statement underscores the critical role of linear motor drives in enhancing productivity. The technology minimizes wear and tear, thereby increasing equipment lifespan, an important aspect in competitive markets.

However, challenges remain in adoption. Not all companies are ready to pivot to linear systems. The initial investment can deter potential users. Many industries continue relying on traditional motor systems, which may hinder progress. As the demand for efficiency rises, linear motor drives must navigate these barriers to achieve their full potential.

Understanding Linear Motor Drive Technology

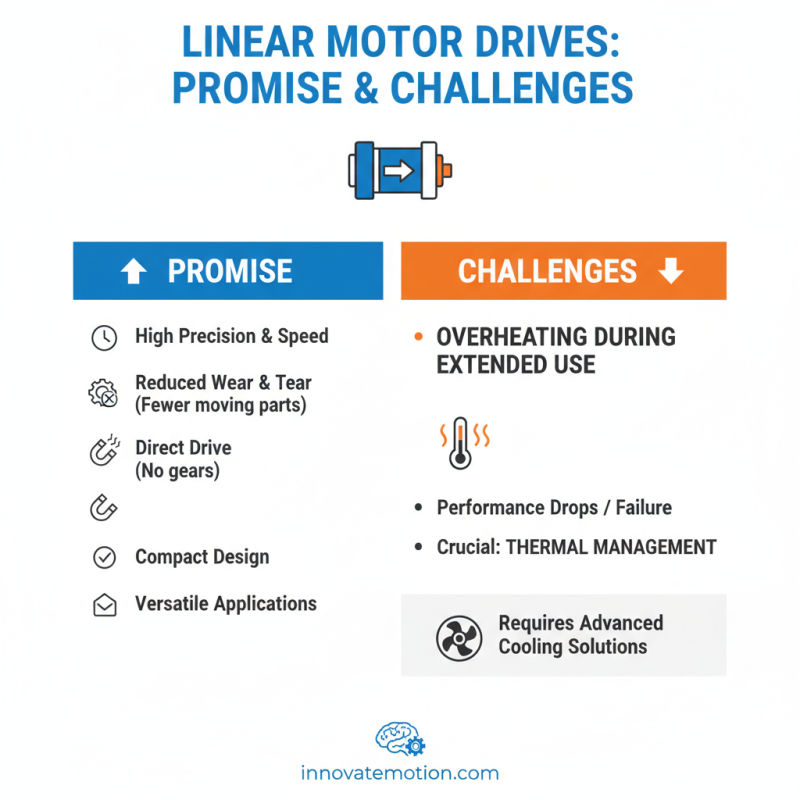

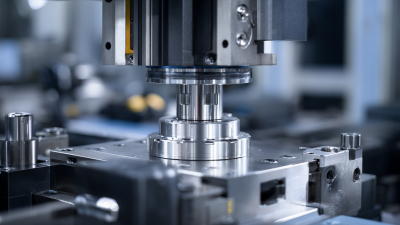

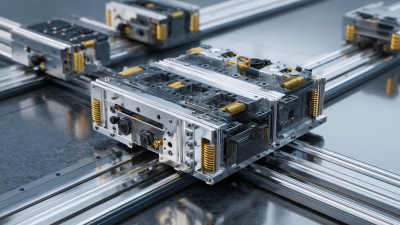

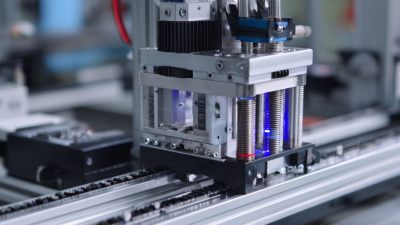

Linear motor drive technology is revolutionizing motion control. It works by using linear motors rather than traditional rotary motors. This shift allows for faster, more precise movements. The direct drive mechanism eliminates mechanical components, reducing wear and tear. These features enable smoother operation in various applications.

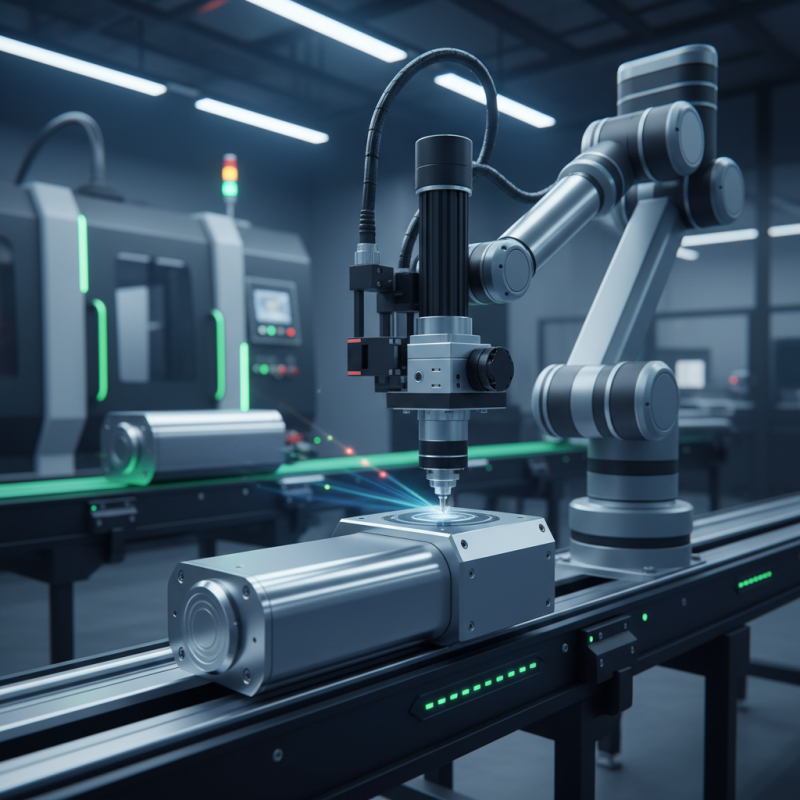

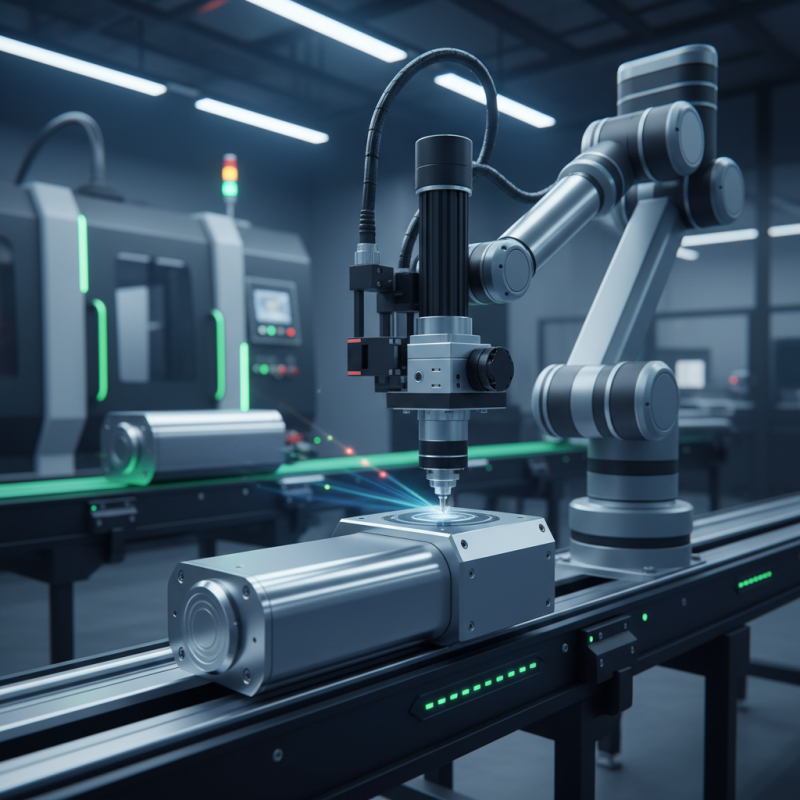

Applications of linear motors can be seen in industries like manufacturing and robotics. They allow for a range of motion not possible with conventional methods. For example, in automated systems, products can move more quickly along assembly lines. However, the integration of this technology can be complex. Not all systems are compatible with linear motor drives. This means that careful planning is essential before switching technologies.

While the advantages are clear, not all aspects are perfected. Cost can be a concern for some operations. Additionally, operators need training to understand how to manage these systems efficiently. Some users may find the initial implementation challenging. These hurdles warrant scrutiny before making a full transition to linear motor drives.

Key Benefits of Linear Motor Drive in Motion Systems

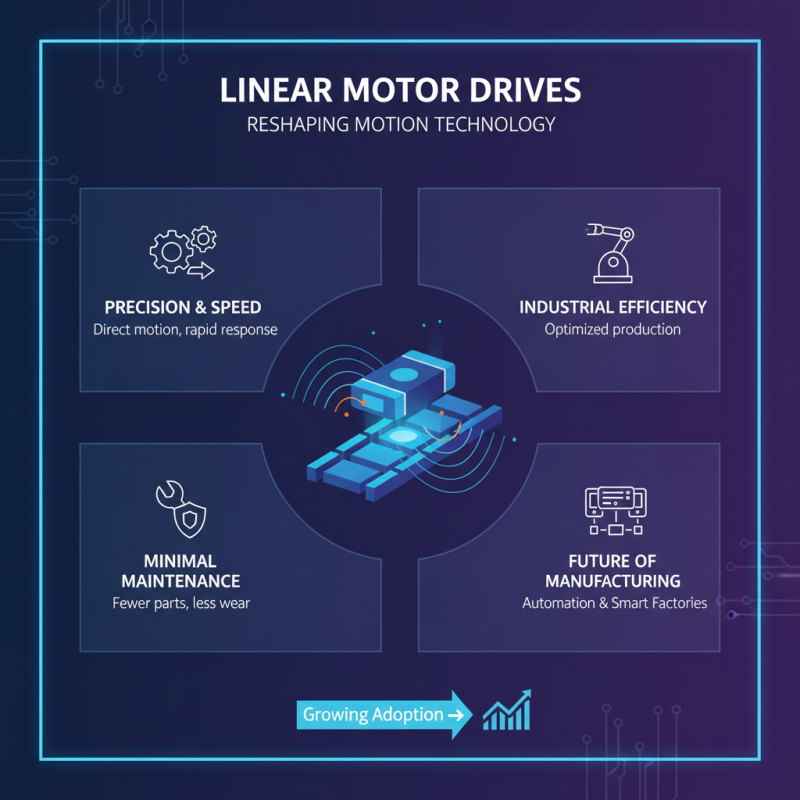

Linear motor drives are revolutionizing motion technology in various industries. These systems are gaining popularity due to their precision and efficiency. According to a report by Research and Markets, the linear motor market is expected to grow at a CAGR of 10.5% from 2021 to 2026. This surge reflects the increasing demand for faster and more accurate motion systems.

One significant advantage of linear motors is their direct motion capability. Unlike traditional rotary motors, they eliminate mechanical components like gears and belts. This feature reduces wear and tear, leading to lower maintenance costs. Furthermore, linear motors can achieve speeds of over 5 meters per second, making them suitable for applications where speed is crucial. However, their high initial cost may deter some businesses from making the switch.

Energy efficiency is another critical benefit. Studies suggest that linear motors can operate with up to 50% less energy compared to traditional systems. In industries grappling with sustainability, this advantage is vital. Yet, users must consider potential challenges, such as sensitivity to environmental factors. These factors can impact performance and reliability, forcing a reassessment of their long-term effectiveness in certain conditions.

Key Benefits of Linear Motor Drive in Motion Systems

Applications of Linear Motor Drive in Various Industries

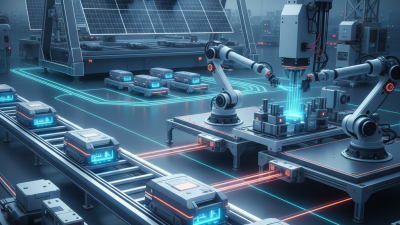

Linear motor drives have revolutionized motion technology across various industries. Their ability to provide precise and rapid movement sets them apart. In robotics, linear motors enable agile movements. They enhance the efficiency of manufacturing processes. For example, assembly lines benefit from high-speed operations. Each component moves smoothly, reducing bottlenecks.

In the transportation sector, linear motors play a critical role. They power high-speed trains and maglev systems. These trains glide above tracks, reducing friction. As a result, they achieve remarkable acceleration and speed. However, the technology still faces challenges. Infrastructure costs can be significant. Maintenance requires careful planning and execution.

Healthcare also utilizes linear motors. Surgical robots assist in delicate procedures. The precision of linear motors improves outcomes. Yet, user training remains crucial. Surgeons must adapt to these advanced tools. This highlights a need for ongoing development and support. Overall, linear motors are changing motion technology, but they require thoughtful implementation.

Why Is Linear Motor Drive Transforming Modern Motion Technology? - Applications of Linear Motor Drive in Various Industries

| Industry |

Application |

Benefits |

Key Features |

| Manufacturing |

Automated assembly lines |

Increased precision and speed |

Direct drive technology |

| Transportation |

Maglev trains |

Reduced friction and energy costs |

High speed with minimal maintenance |

| Medical Devices |

CT and MRI machines |

Enhanced imaging accuracy |

Smooth, quiet operation |

| Robotics |

Robotic arms |

Improved dexterity and control |

High resolution feedback systems |

| Aerospace |

Flight simulation systems |

Realistic training environments |

High-speed response |

Challenges and Limitations of Linear Motor Drive Technology

Linear motor drive technology holds great promise for modern motion systems. However, it also faces significant challenges. One issue is overheating during extended use. Research indicates that thermal management is crucial. Overheating can lead to performance drops or even equipment failure.

Another challenge is the cost of implementation. According to a recent report by industry analysts, initial investment costs can be higher than traditional systems. This can deter smaller businesses from adopting this technology. Paradoxically, while linear motors can reduce long-term operational costs, the upfront financial burden is a hurdle.

Lastly, there is the complexity of integration with existing systems. Compatibility issues often arise. Many manufacturers struggle with aligning legacy technologies with new linear systems. This may lead to prolonged downtime and costly maintenance. The transition to linear motor drives must be approached carefully, considering these real limitations.

Future Trends in Linear Motor Drive Development

Linear motor drives are reshaping motion technology in exciting ways. These systems utilize electromagnetic forces to achieve direct linear motion. The appeal lies in their precision, speed, and minimal maintenance. As industries seek efficiency, linear motors become increasingly vital. Their growing adoption reflects broader trends toward automation and smart manufacturing.

Future trends point toward more compact designs and improved energy efficiency. Innovations like lightweight materials may enhance performance. We can expect integration with AI for smart control. These advances promise to make linear motors even more adaptable across various sectors. However, challenges remain. High costs and technical complexities can hinder widespread implementation.

Tip: Evaluate your application needs closely. Not every scenario benefits from a linear motor. Consider factors like load, speed, and environment. Keep in mind that technology evolves. Staying updated with industry trends can aid decision-making. Another tip: Pilot testing helps reveal practical limitations. Testing new tech in real-world scenarios uncovers potential issues early.