What is a laser machine and how does it work?

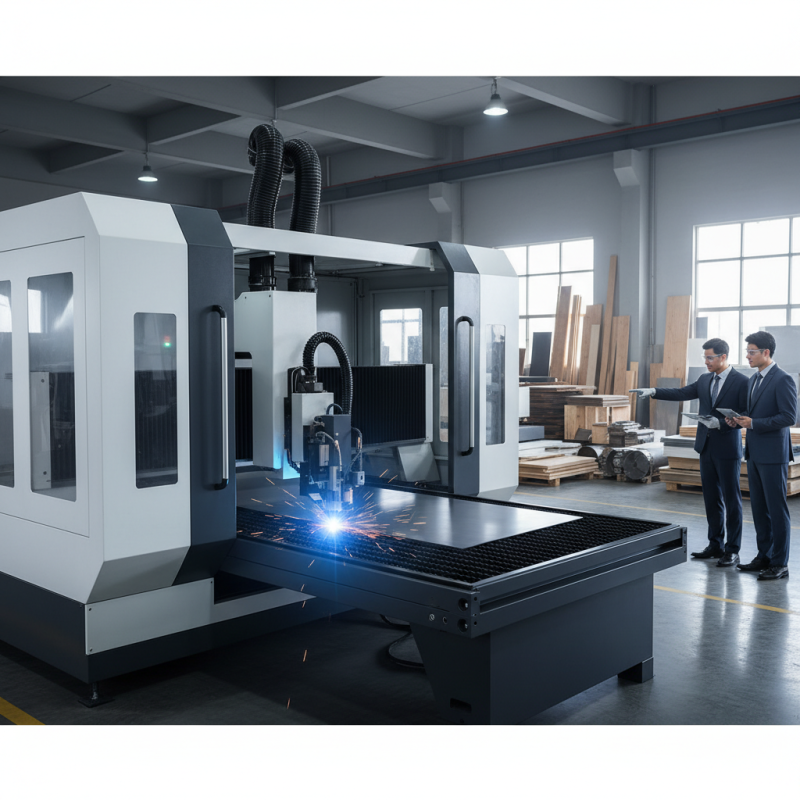

A laser machine is a powerful tool that has transformed various industries. It works by producing a focused beam of light concentrated to cut, engrave, or mark materials with precision. According to Dr. John Miller, a renowned expert in laser technology, “Laser machines have changed the way we approach manufacturing.” His insight highlights the innovative role of laser machines in modern production processes.

These machines utilize highly energized light beams that can safely and efficiently work on numerous surfaces. For instance, they can cut through metal, wood, and plastic with remarkable accuracy. The technology allows for intricate designs that were impossible with traditional methods. The versatility of a laser machine often leads to impressive yet sometimes unexpected results.

However, despite their advantages, there are challenges. The high initial cost can deter small businesses. Additionally, operational safety is crucial; improper usage can lead to accidents. As industries adopt laser machines, they must reflect on these aspects. Balancing innovation with safety and cost remains a pressing issue for many.

What is a Laser Machine?

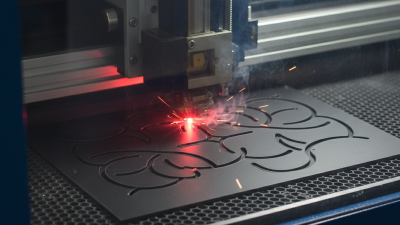

A laser machine is a powerful tool that uses focused light to cut, engrave, or mark materials. It works by emitting a concentrated beam of light, which is amplified through a process called stimulated emission. The mechanism is similar to a flashlight, but with much greater intensity. The laser beam is directed through optics, allowing precise targeting of the material.

In practical terms, various materials can be processed. Common options include wood, acrylic, metal, and textiles. Each material responds differently to the laser's energy. For instance, wood can burn or scorch, while metal requires higher energy levels to achieve effective cutting. This variability means that operators must adjust settings frequently.

Using a laser machine is not without challenges. Calibration can be tricky. Sometimes, the beam may not focus correctly, leading to inconsistent results. Operators must learn to optimize the machine, which can involve trial and error. Even small adjustments can significantly affect outcomes. Understanding the laser’s limits is crucial. The possibilities can be exciting, yet also intimidating for newcomers.

The History and Development of Laser Technology

Laser technology has a fascinating history. The concept of the laser emerged in the 1960s, marking a significant breakthrough. Researchers like Theodore Maiman are credited with creating the first operational laser. Initially, lasers were bulky and limited to research labs. Over time, advancements made them more compact and accessible. By the 1980s, the medical field began to embrace lasers for surgeries.

According to recent industry reports, the global laser market is projected to reach $14 billion by 2025. This growth reflects the increasing use of lasers across various sectors. Applications range from manufacturing to medical treatments. The efficiency of laser machines in cutting and precision makes them invaluable. However, some industries still face challenges. Integration of laser technology can be costly and requires skilled operators.

Tips: Consider the learning curve when adopting laser technology. Training staff is essential for effectiveness. Also, evaluate potential return on investment before making decisions. A careful approach can maximize benefits while minimizing risks. Technology evolves rapidly, but not all advancements are universally applicable. Keep questioning the best fit for your needs.

What is a laser machine and how does it work? - The History and Development of Laser Technology

| Year |

Event |

Description |

| 1960 |

First Laser Invented |

The first operational laser was built by Theodore Maiman at Hughes Research Laboratories. |

| 1970s |

Medical Applications |

Lasers began to be used in medical procedures, including vision correction and surgery. |

| 1980s |

Industrial Adoption |

Laser cutting and engraving technology gained traction within various industries. |

| 1990s |

Advancements in Laser Technology |

Development of fiber lasers and solid-state lasers enhanced performance and applications. |

| 2000s |

Innovation and Research |

Ongoing research led to new applications in telecommunications, defense, and manufacturing. |

How Laser Machines Generate Laser Beams

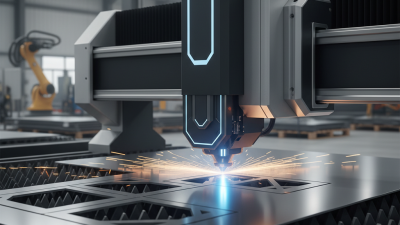

Laser machines operate by generating focused beams of light, which serve various applications in cutting, engraving, and marking. The key to this process lies in the generation of laser beams. Lasers produce light through a process called stimulated emission. This occurs when atoms get excited and release energy in the form of photons.

Inside a laser machine, a gain medium, such as a gas, liquid, or solid material, is energized by an external light source or electrical current. This creates a population inversion, where more atoms are in an excited state than in a lower state. These excited atoms, when stimulated, emit photons. The emitted light then bounces back and forth within a resonator, enhancing its intensity. Finally, a portion of this light escapes through a partially reflective mirror, forming a coherent and focused laser beam.

This beam can penetrate materials with precision, making laser machines invaluable across industries. However, working with lasers requires caution. Misalignment or incorrect settings can lead to subpar results or even safety hazards. Understanding the intricacies of laser generation is crucial for effective use. The potential for error remains, emphasizing the importance of user knowledge and care in handling these powerful machines.

Types of Laser Machines and Their Applications

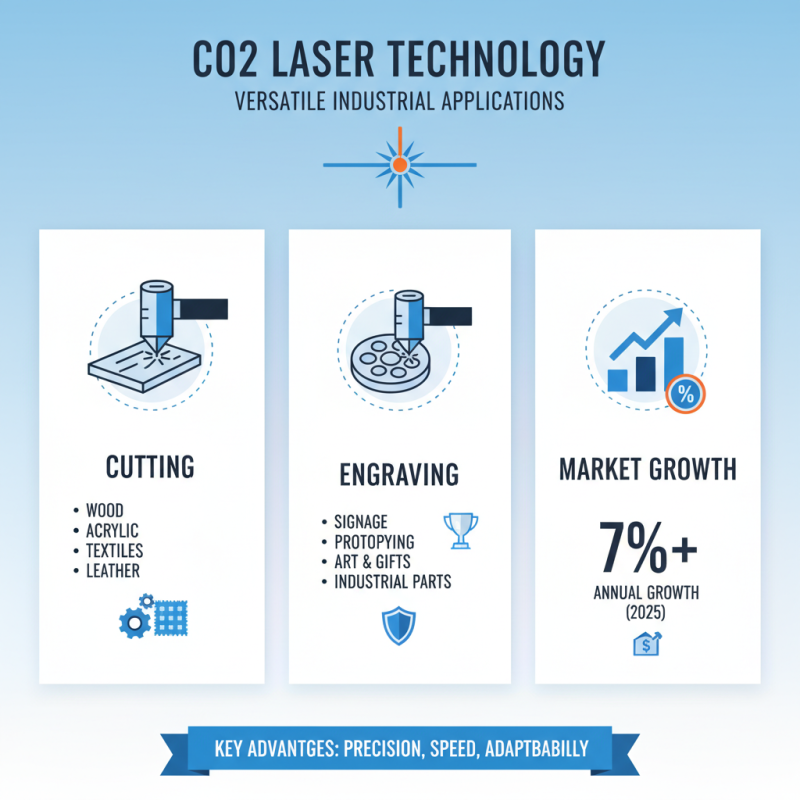

Laser machines come in various types, each serving distinct purposes across different industries. CO2 lasers, for example, are often used for cutting materials like wood, plastic, and textiles. According to a market report, this segment is expected to grow by over 7% annually through 2025. Their versatility makes them popular in signage and engraving applications.

Another type is fiber lasers, known for their efficiency and precision. They excel in metal cutting and welding, with research indicating they can reduce processing time significantly. For instance, fiber laser systems can achieve cutting speeds three to four times faster than traditional methods. Yet, the initial investment in fiber laser technology remains a concern for many small businesses.

Solid-state lasers are also worth noting. They find applications in medical fields for procedures like skin resurfacing or eye surgeries. However, there are challenges in consistent performance and maintenance that can lead to increased operational costs. The high adaptability of these machines often requires regular recalibration, a point often overlooked by new users. Each type of laser machine brings unique benefits but also demands critical consideration regarding application and upkeep.

Understanding the Principles of Laser Operation

A laser machine operates on the principles of stimulated emission of radiation. This process begins when atoms absorb energy, causing them to emit photons. These photons travel in a coherent beam, which is a defining characteristic of laser light. The laser consists of three main components: the gain medium, the pump source, and the optical cavity.

The gain medium plays a crucial role. It can be gas, liquid, or solid. The choice affects the laser's color and intensity. Next, the pump source energizes the medium, generating photons. The optical cavity reflects these photons back and forth, increasing their number until a powerful beam emerges.

Tips: When using a laser machine, always wear proper protective eyewear. The beam can cause serious eye damage even if it seems harmless. Regularly check your equipment for maintenance needs. Inconsistent performance might indicate misalignment or wear.

Improper handling can lead to accidents. Misunderstanding how the machine operates may cause it to function inefficiently. Take time to read manuals and familiarize yourself with safety protocols. Mistakes can teach valuable lessons. Always prioritize safety and knowledge when operating a laser machine.