A laser cutter is a remarkable tool. It uses focused light to cut or engrave materials. This technology has transformed various industries, including manufacturing and art.

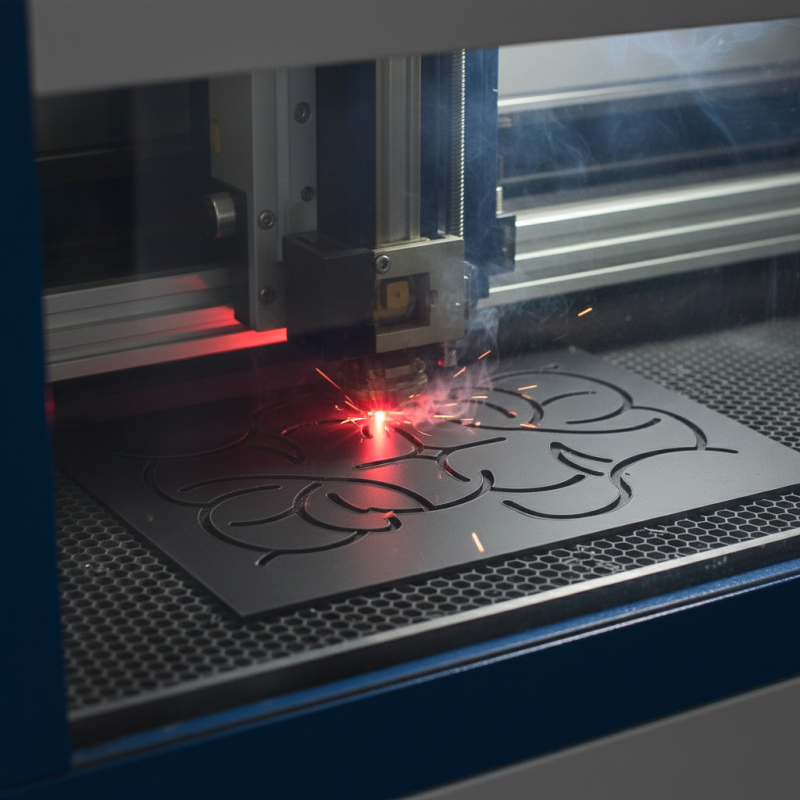

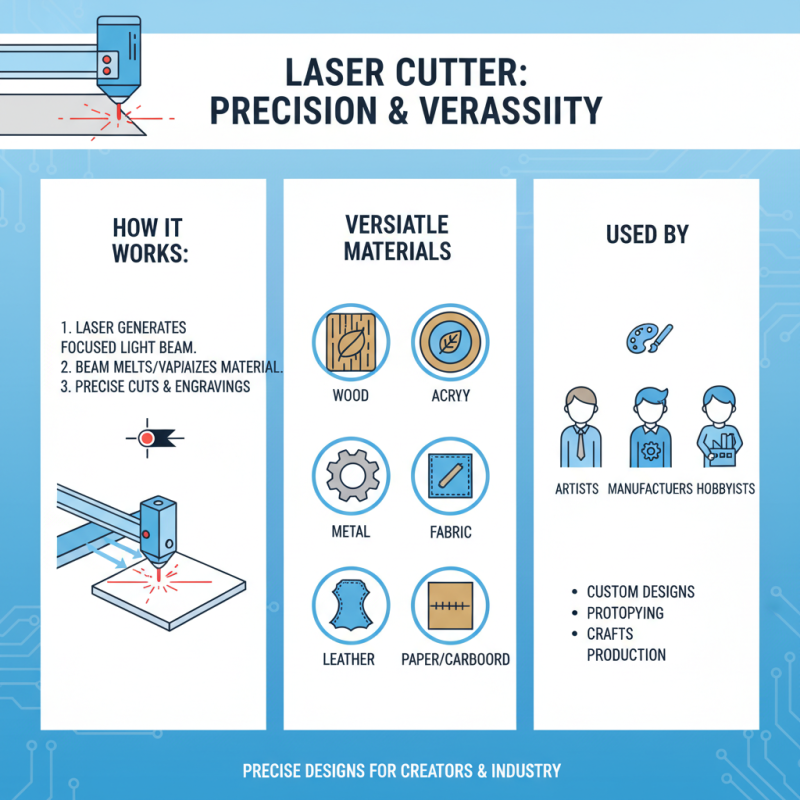

In a laser cutter, a high-powered laser beam is directed onto a material. The intense heat from the laser melts or vaporizes the material. This process allows for intricate designs and precise cuts. Users can create complex shapes that would be hard to achieve otherwise.

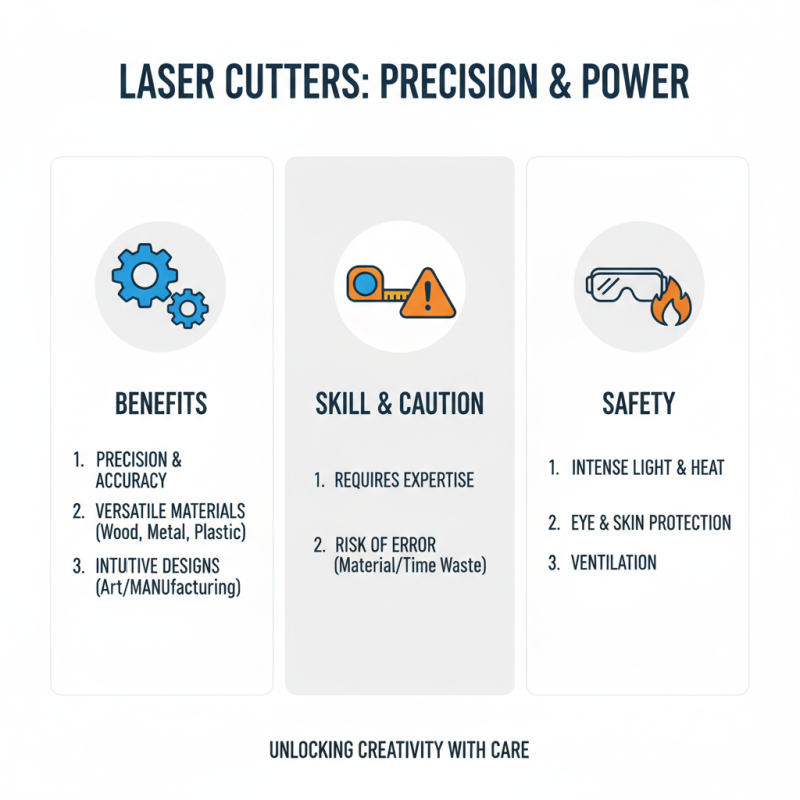

Despite its effectiveness, a laser cutter has limitations. Not all materials are suitable for cutting. Some can produce harmful fumes. Users need to exercise caution and follow safety guidelines. Understanding both the capabilities and constraints of a laser cutter is crucial.

A laser cutter is a powerful tool used for cutting and engraving a variety of materials. It employs a focused beam of light, which is generated by a laser. This beam melts or vaporizes the material in its path. Laser cutters are versatile and can work with wood, acrylic, metal, fabric, and more. Artists, manufacturers, and hobbyists frequently use them for precise designs.

When working with a laser cutter, it's essential to understand its capabilities and limitations. The intensity of the laser, the material type, and the thickness all play significant roles. For example, cutting thick metal requires a stronger and more powerful laser. However, using too much power can lead to burn marks or warped materials. Precision is crucial. Small adjustments can lead to significant variations in the final product.

Safety is also a significant concern. While the machine can create stunning designs, it poses risks if not used properly. Proper ventilation is vital, as many materials release harmful fumes when cut. Users should wear protective glasses to shield their eyes from the intense light. Mistakes can lead to accidents. Careful operation and awareness are necessary to ensure a safe and productive experience.