Exploring the Impact of Linear Motor Applications in Robotics: Trends and Future Projections

The integration of linear motor applications in robotics has triggered a revolution across various industries, marked by significant advancements and growing market potential. According to a report by MarketsandMarkets, the global linear motor market size is projected to reach USD 5.56 billion by 2025, expanding at a CAGR of 7.2% from 2020 to 2025. This growth can be attributed to the increasing demand for precision and speed in automated systems, driven by the rise of Industry 4.0 and smart manufacturing practices. Linear motors provide superior performance characteristics such as high acceleration, accuracy, and minimal maintenance, making them ideal for various robotic applications including manufacturing, logistics, and medical technology. As industries continue to seek innovative solutions to improve efficiency and productivity, the impact of linear motor applications in robotics is expected to increase, paving the way for enhanced automation capabilities and opening up new frontiers for technological advancement.

Impact of Linear Motors on Precision Robotics: Enhancing Accuracy and Efficiency

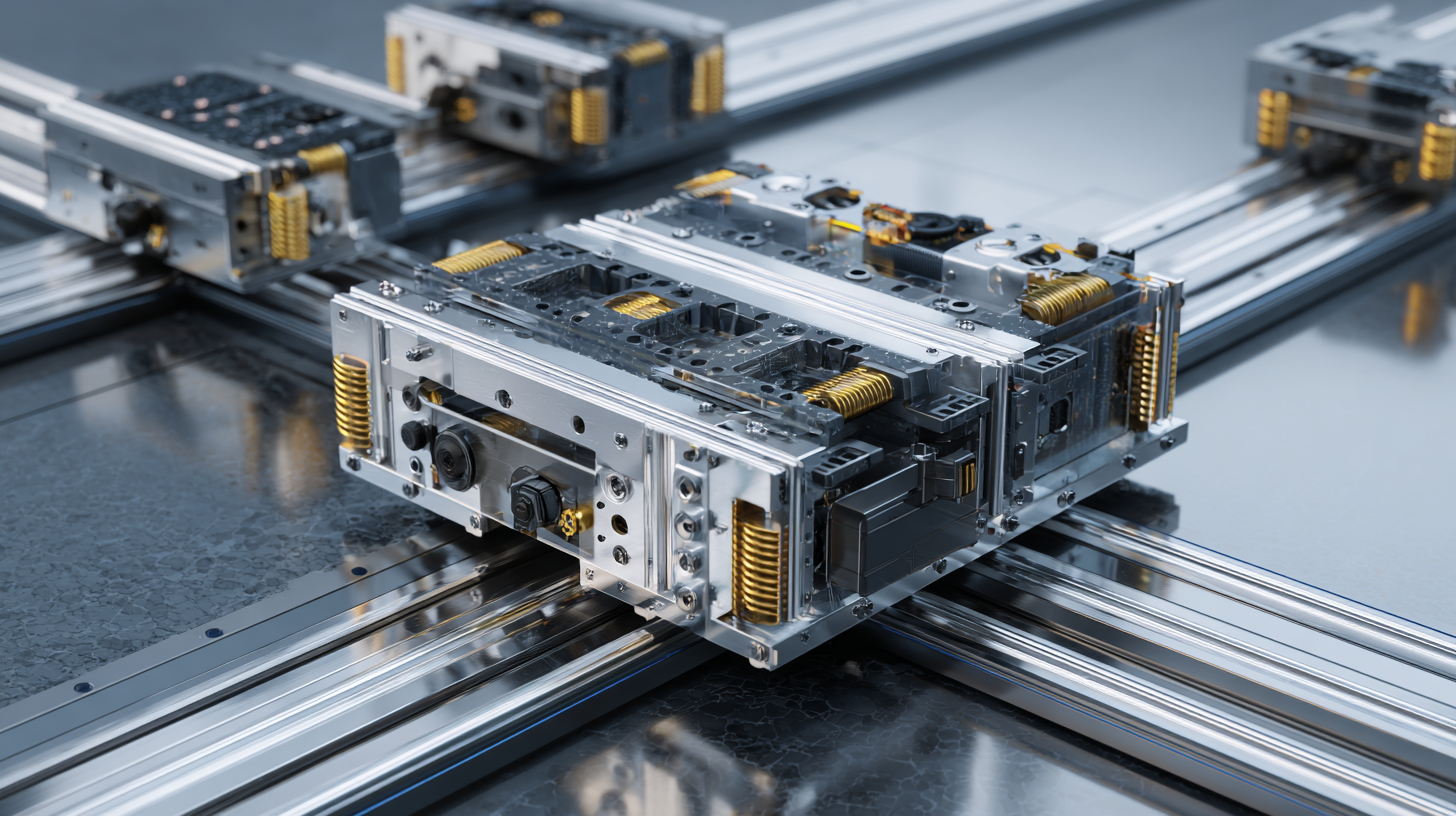

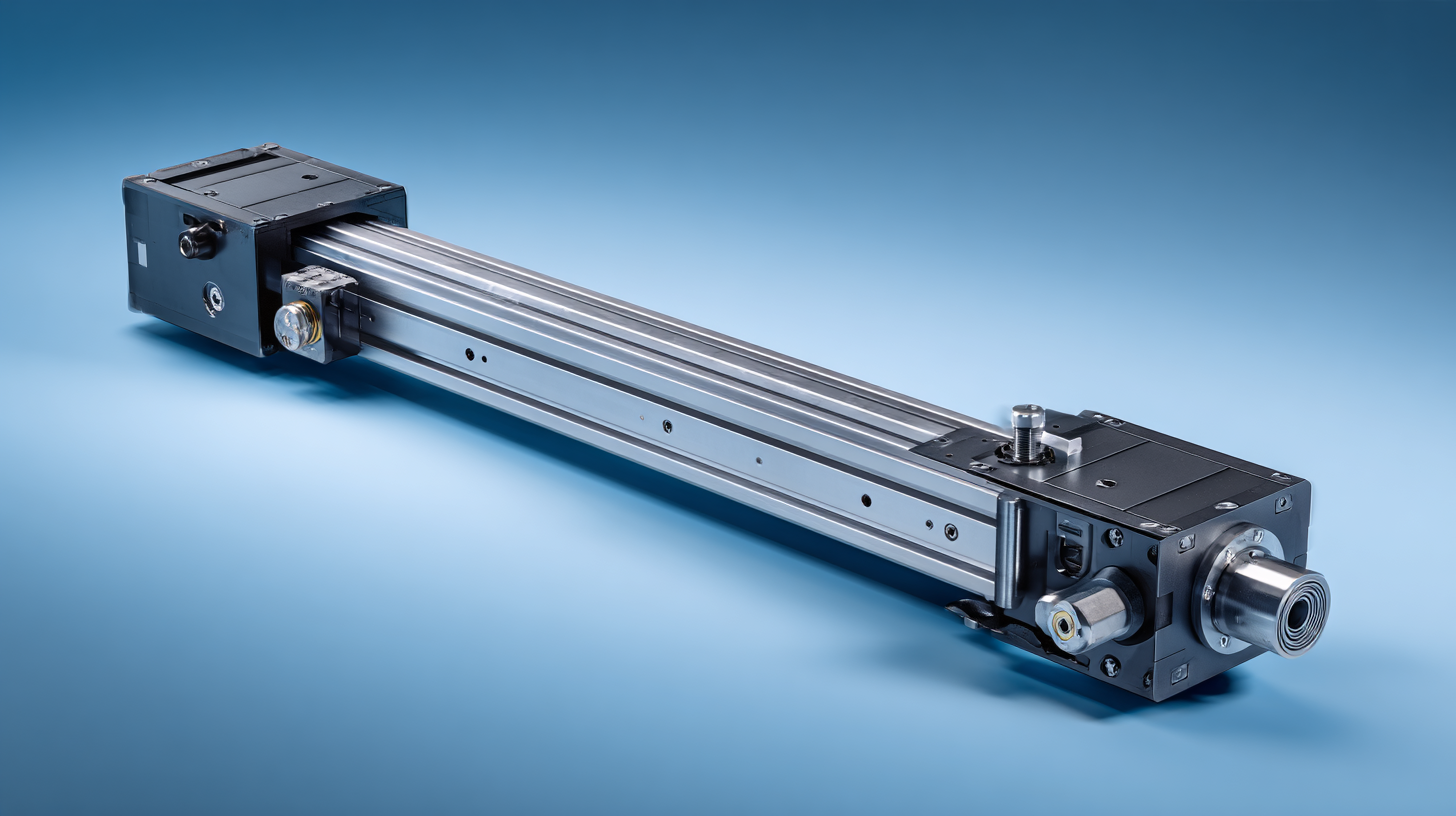

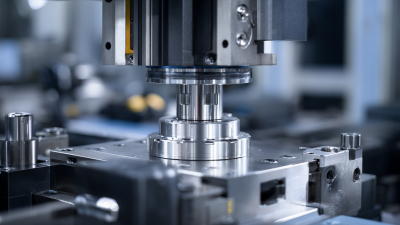

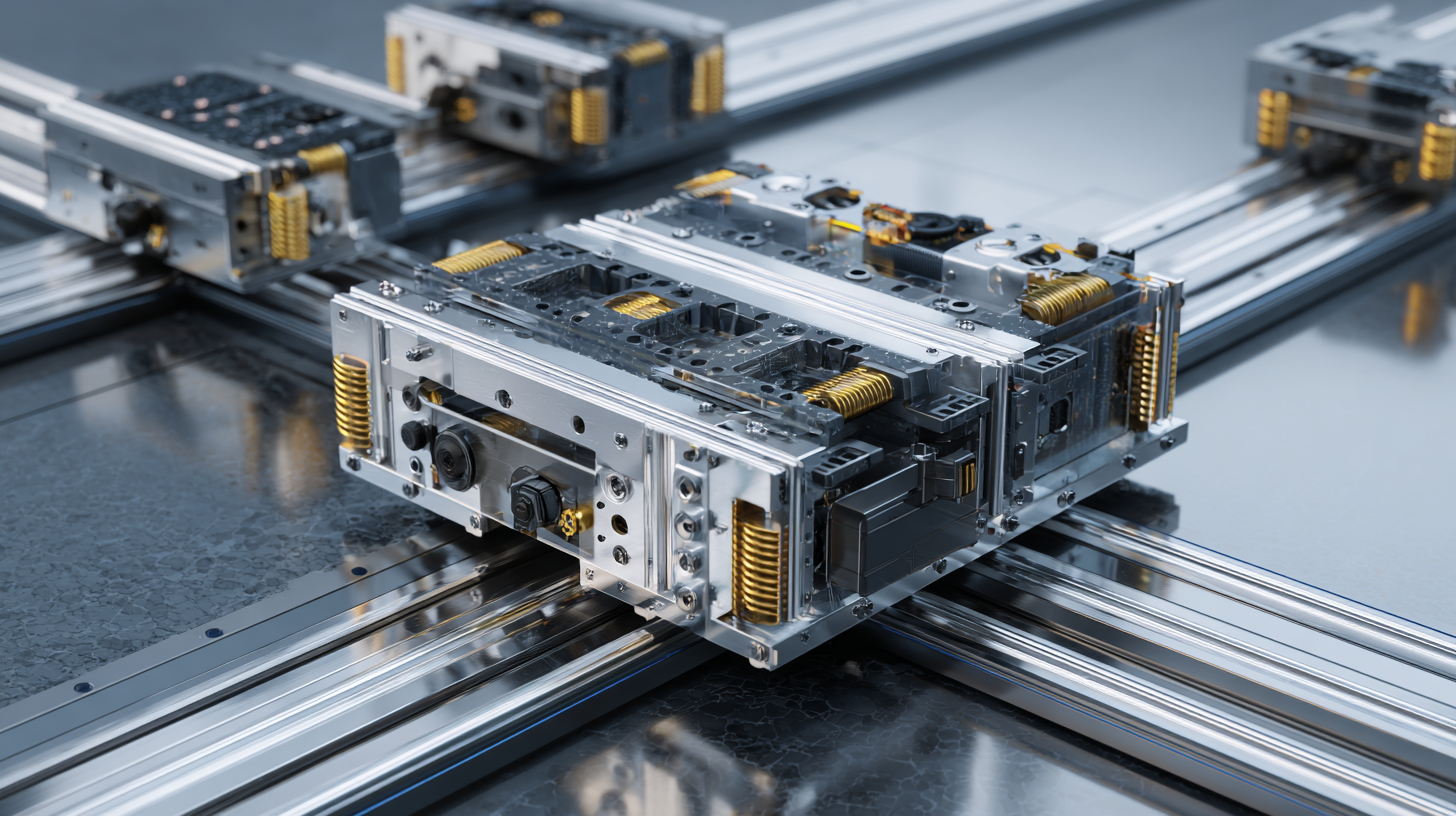

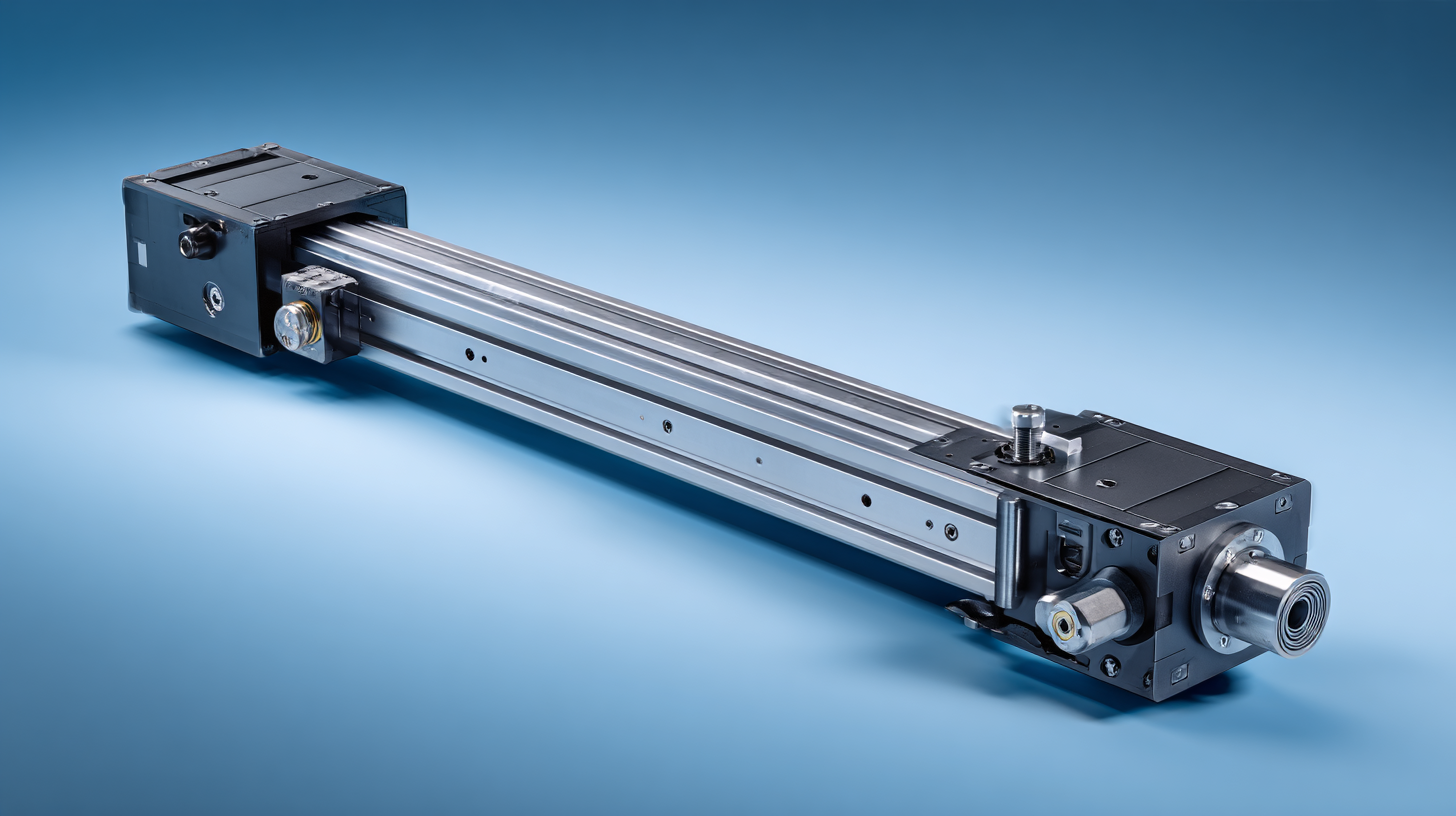

Linear motors are revolutionizing precision robotics by significantly enhancing both accuracy and efficiency. Unlike traditional rotary motors, linear motors directly convert electrical energy into linear motion, eliminating the complexities of gears and belts. This leads to smoother movements and reduces mechanical backlash, which is crucial for applications that require high precision, such as in automated assembly lines and medical robotics. The integration of linear motors allows robots to perform tasks with unparalleled repeatability, diminishing errors and improving overall performance.

**Tip:** When designing robotic systems, consider the payload and the operational environment, as these factors will influence the selection of linear motors. Opt for motors that are rated for the specific load requirements to ensure optimal performance without compromising precision.

Moreover, the trend toward lightweight materials and compact designs in robotics further complements the benefits of linear motors. With advancements in technology, these motors are becoming more efficient, enabling robots to operate at higher speeds while maintaining accuracy. As industries increasingly adopt automation, the demand for innovative linear motor applications is likely to grow, fostering an exciting future for precision robotics.

**Tip:** Regularly assess and update your robotic systems to take advantage of the latest linear motor technologies, ensuring your applications remain at the forefront of efficiency and accuracy.

Exploring the Impact of Linear Motor Applications in Robotics

This chart illustrates the trends in precision robotics performance associated with linear motor applications, highlighting enhancements in accuracy and efficiency over recent years.

Current Trends in Linear Motor Technology: Adoption Rates and Performance Metrics in Robotics

The adoption of linear motor technology in robotics is steadily increasing, driven by the demand for high precision and speed in various applications. According to a recent market report by Research and Markets, the global linear motor market is projected to grow at a compound annual growth rate (CAGR) of over 7% from 2023 to 2030. This growth is primarily fueled by advancements in automation processes across industries, including manufacturing and logistics, where linear motors are becoming essential for improving operational efficiency.

Recent performance metrics highlight that linear motors offer a significantly higher efficiency compared to traditional motor systems. For instance, linear motors can achieve acceleration rates of up to 100 m/s², while also providing precise positioning with an accuracy of ±0.1 mm. These performance metrics are particularly beneficial for robotic applications that require quick and precise movements, such as in assembly lines or surgical robotics.

Tip: When considering the integration of linear motors into robotic systems, it's crucial to evaluate the specific application requirements and the potential return on investment. Analyzing the performance data and understanding the operational environment can provide valuable insights on the suitability of linear motors for your projects. Additionally, keeping abreast of the latest technological developments will help ensure that you make informed decisions.

Exploring the Impact of Linear Motor Applications in Robotics: Trends and Future Projections

| Application Area |

Adoption Rate (%) |

Performance Metric (Speed m/s) |

Year of Data Collection |

| Manufacturing Automation |

75 |

4.5 |

2023 |

| Medical Robotics |

60 |

3.2 |

2023 |

| Logistics and Warehousing |

80 |

5.0 |

2023 |

| Precision Engineering |

65 |

2.8 |

2023 |

| Automotive Robotics |

70 |

4.0 |

2023 |

Future Projections: Market Growth and Innovations in Linear Motor Applications for Robotics

The global industrial automation market is on a robust trajectory, valued at $205.86 billion in 2022 and projected to reach $395.09 billion by 2029, with a compound annual growth rate (CAGR) of 9.8%. This remarkable growth underscores the increasing adoption of various technologies, especially linear motors in robotics, which are essential for enhanced efficiency and precision in applications.

As firms continue to invest in automation, the demand for linear motors, known for their reliability in converting electrical energy into linear motion, is expected to rise significantly.

Moreover, the prospects for the robotics market itself are equally promising, with projections indicating that the robot motor market will expand from $13.96 billion in 2024 to $18.92 billion by 2032, marking a CAGR of 3.8%. Innovations in linear motor technologies are driving advancements in humanoid robots, which are rapidly becoming a competitive segment within the automation landscape.

As humanoid robots like "Tiangong" demonstrate impressive capabilities, including stable running at 6 km/h, the industry anticipates a surge in both talent and investment, suggesting an exciting future filled with opportunities for growth and development in the robotics sector.

Comparative Analysis: Linear Motors vs. Traditional Actuators in Modern Robotic Systems

The advent of linear motor technology has significantly influenced the design and performance of modern robotic systems. Unlike traditional rotary actuators, which rely on gears and pulleys, linear motors offer direct motion along a straight path, resulting in higher efficiency and reduced mechanical complexity. This shift not only enhances the precision of robotic movements but also lowers maintenance requirements due to fewer moving parts. In applications that demand rapid positioning and high speed, such as assembly lines or CNC machining, linear motors demonstrate clear advantages over conventional methods.

Furthermore, a comparative analysis reveals that while traditional actuators may still hold ground in certain cost-sensitive applications, linear motors are becoming increasingly accessible due to advancements in manufacturing processes. Their superior adaptability in various environments, including clean rooms and vibrating contexts, positions them favorably in the robotics landscape. As industries continue to prioritize automation and efficiency, the trend towards integrating linear motors in innovative robotic systems is likely to accelerate, indicating a transformative shift that could redefine operational paradigms across multiple sectors.

Key Industry Players: Leading Companies and Their Contributions to Linear Motor Robotics Advancements

The field of robotics has seen significant advancements through the integration of linear motors, with key industry players spearheading innovations that enhance efficiency and functionality. These companies have developed a range of linear motor applications that are pivotal in robotic systems, facilitating precise movement and control crucial for tasks ranging from manufacturing to surgical procedures.

In the context of endoscopic surgical staplers, the focus on powered versus manual types showcases the versatility of linear motors in medical robotics. Leading firms are investing in the development of linear staplers and cutters, which improve surgical precision and reduce operation times. As these companies continue to innovate, the impact of linear motor technology on the healthcare sector becomes increasingly evident, demonstrating a significant shift towards automation in surgical environments.