2026 How to Choose the Right Thermal Paper Roll Manufacturer?

Choosing the right thermal paper roll manufacturer is vital for businesses that rely on point-of-sale systems and printing solutions. The manufacturer you select can directly impact the quality of your printed receipts. High-quality thermal paper enhances print clarity and longevity. Conversely, poor quality can lead to smudged prints and disappointed customers.

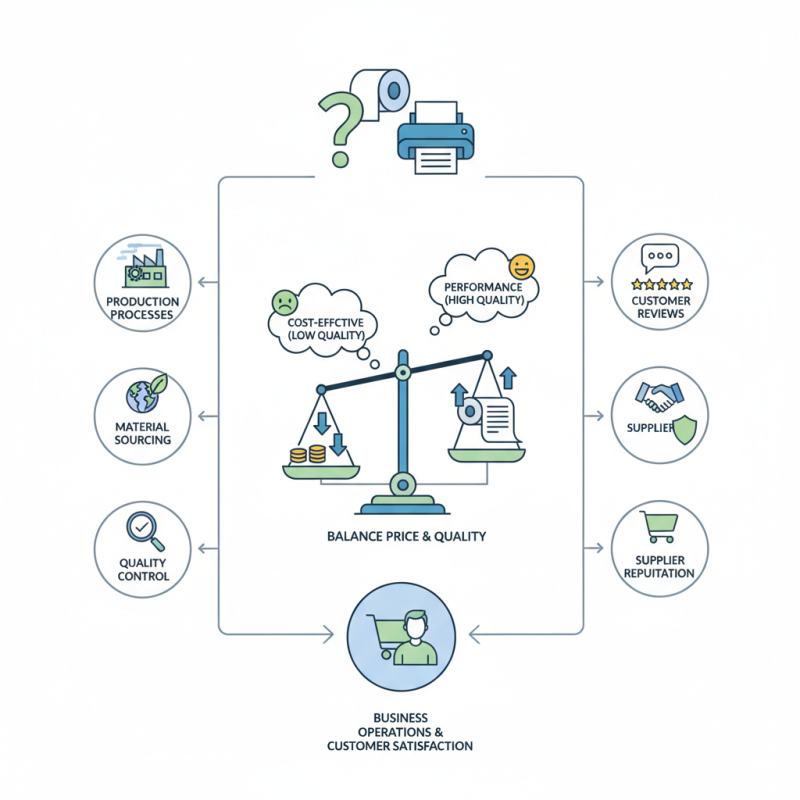

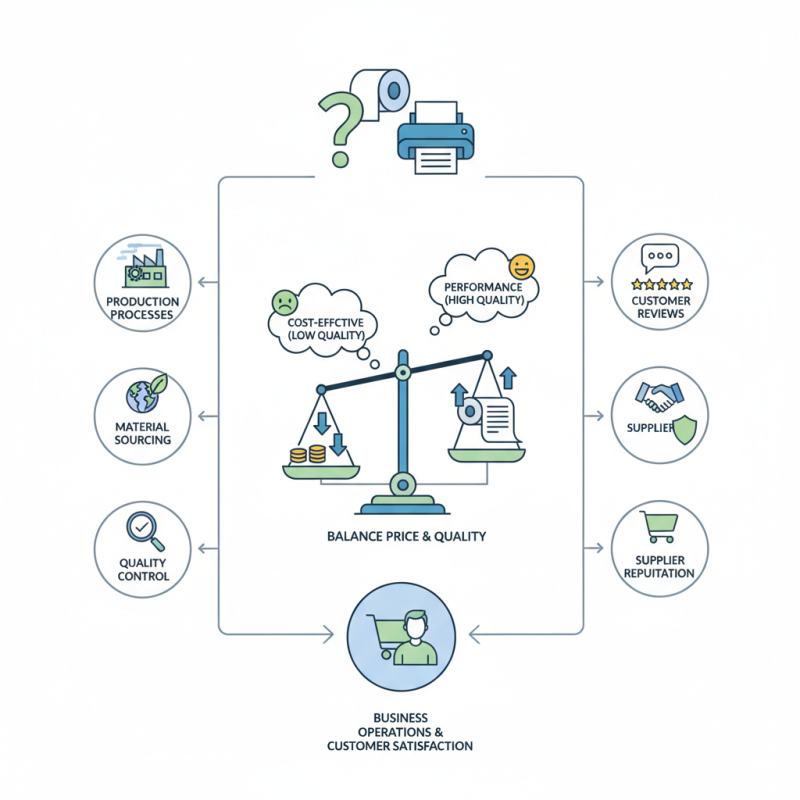

When evaluating manufacturers, consider several factors. Look at their production processes, material sourcing, and quality control measures. A reputable thermal paper roll manufacturer should be transparent about these aspects. Don’t hesitate to ask questions about their products and consider customer reviews. A supplier’s reputation is often an indicator of reliability.

It's essential to reflect on what you prioritize. Cost-effective options might seem appealing but can compromise quality. Balancing price and performance is key. Take time to research and weigh your options carefully. Your choice will affect your business's operations and customer satisfaction.

Understanding Thermal Paper and Its Applications

Thermal paper is a unique type of paper that changes color when exposed to heat. It’s primarily used in printing receipts, labels, and tickets. This paper is coated with a special chemical that reacts to heat, allowing printers to create clear and sharp images. Businesses widely use it for point-of-sale transactions because of its efficiency.

However, not all thermal papers are created equal. The quality can vary significantly between manufacturers. Factors such as brightness, durability, and sensitivity to heat must be considered. Poor quality thermal paper can lead to fading prints or jamming in printers. This can disrupt business operations and cause customer dissatisfaction. It is essential to evaluate samples and seek guidance from manufacturers.

When selecting a thermal paper roll manufacturer, reflect on your requirements. Does your operation demand high-quality prints for long-lasting receipts? Consider the environmental impact of the materials used. Not all thermal papers are eco-friendly. Many options are available, but not all may align with your values. Be mindful of these details in your decision-making process.

Key Factors to Consider When Selecting a Thermal Paper Manufacturer

When selecting a thermal paper manufacturer, you should evaluate several key factors. Quality is paramount. Low-quality paper may fade quickly or not produce clear images. Check for certifications that indicate high manufacturing standards. Always ask for samples before making a decision.

Another important factor is reliability. A good manufacturer delivers on time and maintains consistent quality. Look for reviews or testimonials from other businesses. This can give you insights into their service. It is crucial to evaluate their customer service as well. Prompt responses to inquiries and issues can save you time and frustration.

**Tips:** Always keep communication open. Transparency from the manufacturer builds trust. Consider local suppliers. This can help with shipping times and costs. Lastly, visit the factory if possible. Observing operations firsthand can reveal a lot about their practices.

Key Factors to Consider When Selecting a Thermal Paper Manufacturer

This chart represents the key factors that influence the selection of a thermal paper roll manufacturer. Data collected from industry surveys highlights the importance of cost, quality, supply chain reliability, and customer service in decision-making.

Evaluating Product Quality: Certification and Compliance Standards

When choosing a thermal paper roll manufacturer, product quality is crucial. Certification and compliance with industry standards can significantly impact the overall performance of thermal paper. According to the International Thermal Paper Association, 30% of manufacturers do not meet basic quality benchmarks. This can lead to issues like poor image durability and fading.

Look for certifications such as ISO 9001 and RoHS compliance. These ensure that the manufacturer follows quality management practices. Testing for chemical safety and environmental impact is essential. A manufacturer with proper certifications indicates a commitment to quality and sustainability. However, it’s important to note that not all manufacturers will have visible certifications. This can be misleading and may reflect issues in their production processes.

Evaluating the composition of thermal coating is also vital. Understanding whether the manufacturer uses BPA-free coatings is essential for safety and environmental reasons. Recent studies show that 45% of consumers prefer BPA-free options. Some manufacturers may hesitate to disclose the exact composition of their products. This lack of transparency can make it difficult for businesses to make informed decisions. Always ask for detailed product specifications and test results before making a choice.

2026 How to Choose the Right Thermal Paper Roll Manufacturer? - Evaluating Product Quality: Certification and Compliance Standards

| Parameter | Standard/Certification | Description |

| ISO 9001 | Quality Management Systems | Ensures consistent quality in products and services. |

| FSC Certification | Forest Stewardship Council | Indicates sustainable sourcing of raw materials. |

| REACH Compliance | Registration, Evaluation, Authorisation and Restriction of Chemicals | Regulates chemicals to protect human health and the environment. |

| RoHS Compliance | Restriction of Hazardous Substances | Limits the use of specific hazardous materials in electronic products. |

| ANSI Standards | American National Standards Institute | Ensures product safety and reliability in the thermal paper industry. |

Comparing Pricing Structures and Minimum Order Quantities

Choosing the right thermal paper roll manufacturer requires careful consideration, especially regarding pricing structures and minimum order quantities. A recent industry report reveals that manufacturers often vary widely in their pricing models. Some may offer bulk discounts, while others set rigid prices per roll. Understanding these structures is crucial for businesses looking to manage costs effectively.

Minimum order quantities can significantly impact your purchasing strategy. Data indicates that many manufacturers present a minimum order quantity ranging from 1,000 to 10,000 rolls. This discrepancy can pose a challenge. Ordering too much can lead to excess inventory. Conversely, ordering too little might increase overall costs in the long run. Businesses must weigh their current needs against potential growth.

It's important to analyze your usage patterns carefully. What if your demand fluctuates? Are you prepared to handle overstock? These inquiries can help you navigate uncertain market conditions. Also, consider the quality of the thermal paper. Sometimes, a lower price isn't worth sacrificing quality. Balancing cost with quality and flexibility is key to making an informed decision.

Assessing Customer Support and Service Reliability in Manufacturers

Choosing the right thermal paper roll manufacturer goes beyond product quality. Customer support and service reliability play a crucial role in the selection process. According to a recent industry report, 70% of businesses prioritize responsive customer service when choosing suppliers. This shows the importance of having a reliable support system in place.

Manufacturers that offer comprehensive customer support can significantly enhance a buyer's experience. It is essential to evaluate response times and the availability of support channels. Some manufacturers provide 24/7 assistance, fostering trust and ensuring quick resolutions to issues. However, not all companies meet this standard, and clients may find themselves waiting days for a response.

Furthermore, consistent communication is vital. Regular updates on order status can minimize uncertainties. Unfortunately, many manufacturers fall short in this area. A survey indicated that 40% of companies felt uninformed about their orders, affecting their overall satisfaction. This gap underscores the need for greater transparency and reliability in service. Investing time to evaluate these aspects can lead to significant long-term benefits.