The Future of Fabrication Unlocking the Potential of Laser CNC Machines for Metalworking

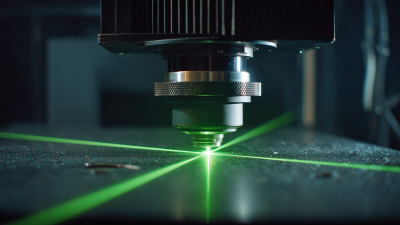

As the metalworking industry continues to evolve, the advent of advanced technologies is reshaping traditional fabrication methods. Among these innovations, the laser CNC machine for metal stands out as a revolutionary tool that enhances precision, efficiency, and versatility in manufacturing processes. This cutting-edge equipment utilizes laser technology to execute intricate designs and cuts with unprecedented accuracy, making it an invaluable asset for fabricators looking to remain competitive in a rapidly changing market.

By unlocking the potential of laser CNC machines, metalworking professionals can not only improve production speed and quality but also explore new possibilities in design and functionality. This article delves into the future of fabrication, highlighting how laser CNC machines are set to transform the landscape of metalworking, and inviting industry players to harness this technology for sustainable growth and innovation.

Exploring the Advantages of Laser CNC Technology in Precision Metalworking

The advent of laser CNC technology is transforming precision metalworking, offering numerous advantages that enhance efficiency and accuracy in fabrication processes. One of the most significant benefits is the high precision and rapid machining capability that lasers provide. This technology allows for intricate designs and patterns to be executed with remarkable accuracy, making it ideal for industries that require fine detailing and complex geometries. For example, recent advances in high-power laser cutting have demonstrated that fine energy density facilitates fast and effective material manipulation, ensuring quality results without the risk of deformation often associated with traditional machining methods.

In addition to precision, laser CNC machines contribute to sustainability in manufacturing. The adoption of laser cutting technology reduces waste, as the process generates minimal scrap when compared to conventional machining techniques. Moreover, innovations such as water-jet guided laser technology are expanding the potential applications of lasers in processing brittle materials, further showcasing their versatility. As the industry moves toward smarter manufacturing solutions, integrating laser CNC technology into metalworking not only boosts productivity but also aligns with the growing demand for environmentally friendly production practices.

The Future of Fabrication: Unlocking the Potential of Laser CNC Machines for Metalworking

| Feature |

Description |

Advantages |

Applications |

| Precision Cutting |

Utilizes focused laser beams to achieve intricate designs |

High accuracy, minimal kerf, reduced waste |

Aerospace, automotive, custom art pieces |

| Speed and Efficiency |

Rapid cutting speeds that enhance productivity |

Reduced production times, lower labor costs |

Mass production, rapid prototyping |

| Material Versatility |

Can cut various metals, from aluminum to stainless steel |

Wider range of applications, adaptability |

Fabrication, renovation, signage |

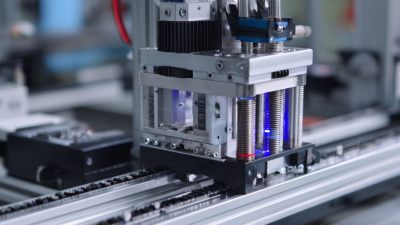

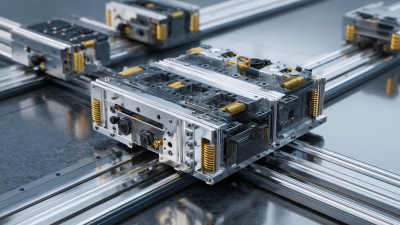

| Automation and Integration |

Easily integrates with CAD and CAM systems for automated workflows |

Increased efficiency, lower human error |

Industrial manufacturing, precision engineering |

Key Applications of Laser CNC Machines in Various Industries

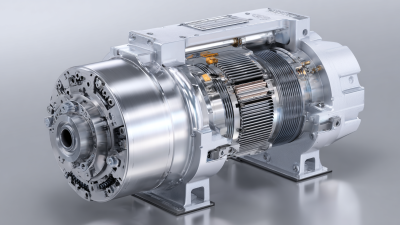

Laser CNC machines are rapidly transforming the metalworking landscape across various industries through their precision and efficiency. With the ability to execute intricate designs and cuts, these machines utilize advanced technologies such as fiber lasers, CO2 lasers, and solid-state lasers. The market for laser cutting machines is anticipated to grow significantly, supported by their adoption in sectors such as automotive, aerospace, and manufacturing. The pandemic underscored the importance of automation and digitization, prompting industries to invest in these sophisticated systems for enhanced productivity.

Key applications of laser CNC machines include cutting, engraving, and marking, which cater to a diverse array of manufacturing needs. Fiber lasers are notably favored for their speed and efficiency, while CO2 lasers excel in engraving applications. As companies increasingly rely on automated solutions, the demand for semi-automatic and robotic systems is on the rise. This evolution signifies a broader trend towards integrating automation and precision in production processes, ensuring that industries can meet the increasing demand for customized and high-quality products.

The Future of Fabrication: Key Applications of Laser CNC Machines in Various Industries

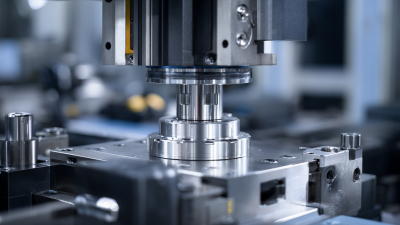

Comparative Analysis: Laser CNC Machines vs Traditional Metalworking Methods

Laser CNC machines represent a significant advancement in the metalworking industry, offering distinct advantages over traditional methods such as milling and welding. Unlike conventional techniques that rely heavily on physical tooling and manual labor, laser CNC technology employs high-powered lasers to cut, engrave, and shape metals with precision and speed. This not only streamlines production processes but also reduces material waste, leading to cost savings and greater efficiency.

Tips: When considering a transition to laser CNC technology, small businesses should start by investing in modular systems that allow for scalability. This will enable them to adapt to varying production demands without overcommitting resources. Additionally, proper training for operators is essential to fully leverage the capabilities of the equipment.

Moreover, laser CNC machines can handle complex designs that would be challenging or impossible with traditional methods. Their ability to execute intricate patterns with high fidelity opens up new avenues for creativity and innovation in metalworking. As industries continue to embrace automation, companies that integrate laser technology are poised to stand out in a competitive marketplace.

Tips: It’s beneficial to collaborate with experts who can provide insights into optimizing laser cutting strategies. Regular maintenance and software updates can also enhance machine performance, ensuring that your operations remain at the forefront of technological advancements.

Understanding the Economic Impact of Laser CNC Fabrication on Production Costs

The advent of laser CNC machines has heralded a new era in metalworking, revolutionizing the fabrication process. One of the primary economic impacts of laser CNC fabrication is the significant reduction in production costs. Traditional methods often require multiple setups and intricate tooling, which can accumulate expenses quickly. In contrast, laser CNC technology streamlines operations by enabling precise cuts and complex designs with minimal manual intervention, effectively decreasing labor costs and time associated with production.

Furthermore, this advanced fabrication method enhances material efficiency. Laser CNC machines can achieve cutting tolerances that minimize waste, thereby optimizing the use of raw materials. The ability to process various metal types with high precision means companies can diversify their offerings without incurring additional overhead. As businesses adopt this technology, they can expect not only a lower cost per unit but also an increase in overall productivity, leading to improved profit margins and competitiveness in the manufacturing sector.

Future Trends: Innovations in Laser CNC Technology and Their Implications for Metalworking

The landscape of metalworking is undergoing a revolutionary transformation, largely driven by advancements in laser CNC technology. As industries strive for greater precision and efficiency, innovations such as fiber lasers and advanced motion controls are redefining production capabilities. These technologies offer enhanced cutting speeds, improved quality of finishes, and the ability to work with a wider variety of materials, including thin and thick metals, composites, and alloys. The integration of artificial intelligence and machine learning into laser CNC systems also promises to optimize the workflow, reduce errors, and predict maintenance needs, leading to increased machinery uptime.

Moreover, the future of fabrication with laser CNC machines heralds a new era of customization and small-batch production. As demand for bespoke products rises, manufacturers can leverage the flexibility of laser technology to create intricate designs that are both cost-effective and time-efficient. The potential for automation through robotics further complements these systems, enabling seamless transitions from design to production while minimizing human intervention. This synergy not only enhances productivity but also paves the way for innovative applications in various sectors, including aerospace, automotive, and consumer goods. As these trends continue to evolve, metalworking firms that adopt these cutting-edge technologies will position themselves at the forefront of the industry.