10 Essential Tips for Choosing the Right Laser Machine for Your Needs?

In the ever-evolving world of fabrication, selecting the right laser machine is crucial for success. According to Dr. Emily Carter, a leading expert in laser technology, "Choosing the correct laser machine can make or break your project." With so many options available, understanding your specific needs is essential.

One must consider various factors such as power, speed, and material compatibility. A powerful laser can cut through metal quickly, while a lower-powered option may be better for delicate materials. You might think a high-end machine guarantees quality, but it's not always the case. A mismatch in your requirements can lead to operational challenges.

Exploring the laser machine landscape can feel overwhelming. Take time to evaluate your business's unique demands. Reflect on previous projects and what machinery was effective or inadequate. Finding a balance between features and budget is key. Embrace the imperfections and learn from past experiences; they will guide your decision-making process moving forward.

Factors to Consider: Power Range and Its Impact on Laser Performance

When choosing a laser machine, the power range is crucial. The laser's wattage affects its cutting and engraving capabilities. For instance, machines with lower wattage, around 30-40 watts, are suitable for thin materials. However, they struggle with thicker materials. On the contrary, higher wattage machines, exceeding 100 watts, excel in cutting through metals and dense materials. A report from the Laser Institute of America indicates that power considerations significantly influence operational efficiency.

It's essential to assess your specific needs. A 60-watt laser may suffice for hobbyists working on wood or acrylic. Yet, for industrial applications, a 120-watt system might be necessary for optimal performance. Power isn't the only factor; the machine's design and mechanics also play a role in its effectiveness. Improper cooling systems can lead to reduced performance, even if the power range appears adequate.

Moreover, consider the intention behind your use. Are you engaging in intricate designs or high-volume production? Each requires different power dynamics. Not all projects need high power; sometimes moderation is beneficial. Reflecting on these elements and gathering insights from professionals can guide your decision. A well-informed choice will enhance productivity and save costs in the long run.

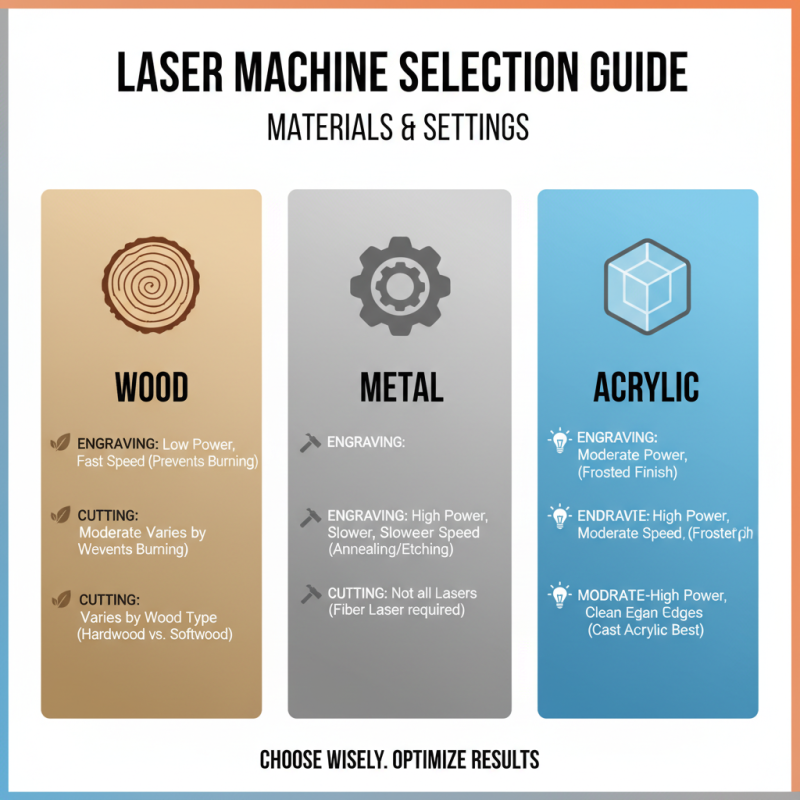

Assessing Material Compatibility: Wood, Metal, and Acrylic Laser Usage

When selecting a laser machine, it's crucial to consider the materials you'll be working with. Three common materials are wood, metal, and acrylic. Each requires different laser settings and power levels for optimal results. For instance, wood engraving often requires lower power and a faster speed. This prevents burning while still achieving a clear finish. However, knowing the type of wood is important. Some hardwoods may resist engraving better than softwoods.

Metal cutting is entirely different. It often demands higher power and slow movement. This can create more heat and stress on the machine. Metal also reflects laser light, which might affect the cutting quality. Thus, some machines might struggle with certain metals. You may need to test different settings. Mistakes can happen here, often leading to wasted material.

Acrylic is known for its versatility in laser applications. Cutting acrylic requires specific speeds and focuses to avoid melting edges. Many users overlook this, leading to poor results. Additionally, colored acrylic can behave unpredictably. A machine’s capability to handle both regular and colored acrylic is key. Testing before production can save time and resources. Consider the potential learning curve with various materials.

Understanding Laser Technology: CO2 vs. Fiber vs. Diode Lasers

When choosing a laser machine, understanding the differences among CO2, fiber, and diode lasers is crucial. CO2 lasers are versatile and can easily cut through non-metal materials like wood, acrylic, and fabric. They're popular for engraving and etching as well. However, they can be less efficient for metal cutting compared to fiber lasers. This could lead to frustration if your work demands high precision on metals.

Fiber lasers excel at cutting metals. They are more energy-efficient and can handle various thicknesses with ease. However, they may not perform well with non-metal materials. This could limit your projects and require you to invest in additional equipment. Diode lasers are typically the least powerful. They serve well for basic engraving tasks on soft materials. Yet, their limitations in cutting and engraving could leave you wanting more.

It's essential to reflect on your specific needs. Consider the materials you will be working with and the types of projects you envision. Each technology has its pros and cons. Weighing these against your goals can help you make a more informed decision. Ultimately, a deep understanding of these laser types might save you time and resources in the long run.

Comparison of Laser Types: CO2 vs. Fiber vs. Diode

This chart compares the average operational cost per hour of three different types of laser machines: CO2, Fiber, and Diode lasers. Understanding these costs can help you make an informed decision based on your budget and specific needs.

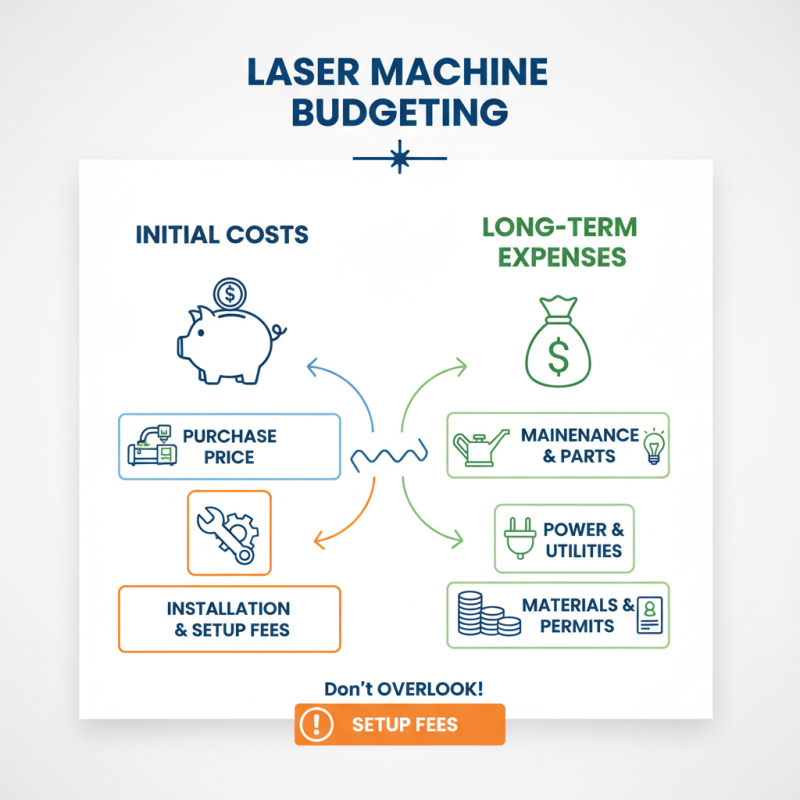

Maintenance and Support: Importance of Warranty and Service Options

When selecting a laser machine, maintenance and support are crucial factors. A strong warranty can safeguard your investment. It ensures that defects or issues are covered, reducing potential costs. Consider how long the warranty lasts. Some machines offer up to three years of coverage, while others may not provide as much protection.

Support options are equally important. Look for companies that offer accessible customer service. Quick responses to inquiries can save you time and frustration. Some might even offer training for new users. This can make a big difference, especially for beginners.

Tip: Investigate the service history of the provider. Ask about their response times and how often they conduct maintenance on their equipment. A reliable manufacturer will have a solid track record. Additionally, consider local service availability. Fast assistance can minimize downtime, which is valuable. Don’t overlook these details; they are vital for long-term satisfaction with your laser machine.

10 Essential Tips for Choosing the Right Laser Machine for Your Needs

| Feature |

Importance |

Considerations |

Service Options |

| Power |

Determines the speed and efficiency of cutting |

Choose based on material types |

Check for onsite service availability |

| Size |

Affects workspace and material size |

Consider your workspace dimensions |

Look for technical support options |

| Cooling System |

Prevents overheating |

Air vs. water cooling systems |

Evaluate maintenance terms |

| Control Software |

Ease of use and functionality |

Compatibility with design programs |

Availability of software updates |

| Warranty |

Protection against defects |

Length and coverage details |

Understand service terms under warranty |