10 Essential Tips for Choosing a Linear Motor System

In the realm of automation, selecting the right linear motor system is crucial. Experts emphasize its significant impact on performance and efficiency. Dr. Emily Zhang, a renowned authority in motion control technology, once stated, "A precise linear motor system can redefine operational boundaries for manufacturers." This insight highlights the necessity of making informed choices.

When considering a linear motor system, various factors come into play. Applications differ widely, influencing requirements in speed, accuracy, and load capacity. Buyers often overlook maintenance needs or integration challenges. The consequences of these oversights can lead to inefficient operations and increased costs.

Moreover, the right linear motor system should align with future technological advancements. As industries evolve, adaptability is key. Choosing a subpar system might limit growth potential. Such decisions demand careful evaluation and reflection on long-term goals and capabilities.

Understanding Linear Motor Systems and Their Applications

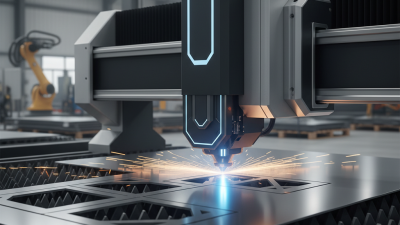

Linear motor systems provide innovative solutions in various industries. They are known for their precision and speed. Manufacturing plants often use linear motors for automation. These systems move components rapidly, enhancing production efficiency. However, selecting the right system can be challenging. A clear understanding of application needs is crucial.

In robotics, linear motors help achieve smooth movements. They reduce mechanical wear and improve lifespan. Yet, one must consider the environmental factors. Dust and moisture can affect performance. Therefore, choosing a suitable protective casing is important. In healthcare, linear motors position medical equipment accurately. They ensure patient safety and comfort. However, one must evaluate maintenance requirements. Frequent checks are essential to avoid unexpected failures.

Understanding the specific requirements of a project is vital. Linear motor systems vary in design and capability. It's easy to overlook compatibility factors. Each application may have unique constraints. Addressing these can lead to better outcomes. Proper analysis of needs will guide the selection process effectively.

Comparison of Linear Motor Systems Efficiency and Speed

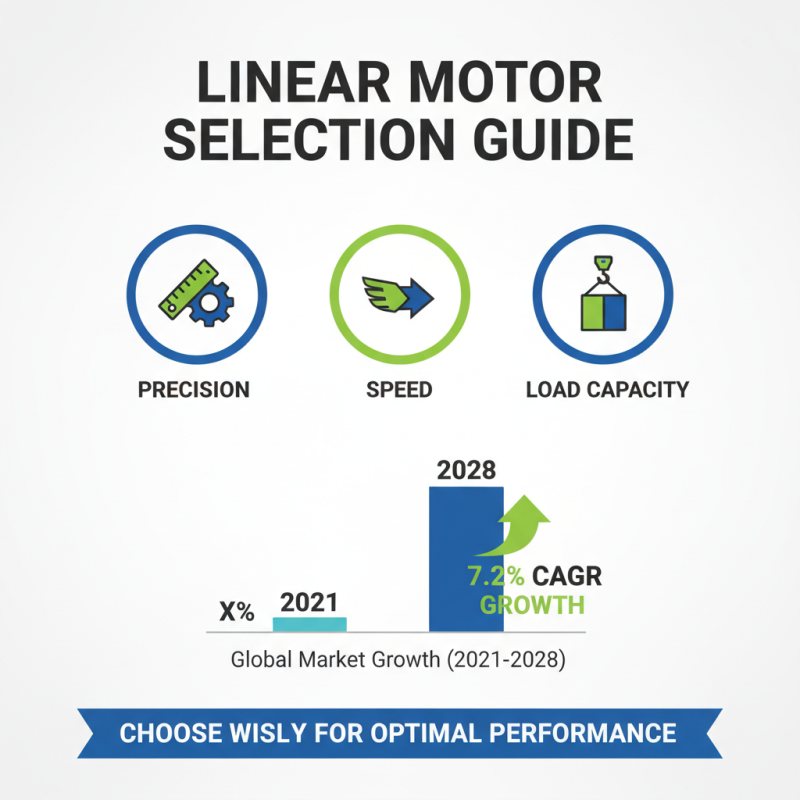

Key Factors to Consider When Selecting Linear Motor Systems

When selecting a linear motor system, several key factors come into play. The effective performance of these systems often relies on precision, speed, and the load they will carry. According to a recent industry report, the global linear motor market is expected to grow at a CAGR of 7.2% from 2021 to 2028. This growth underscores the importance of making the right choice for specific applications.

Tip: Consider the required speed. Different applications may need varying acceleration and velocity profiles. For example, some applications require rapid movements, while others prioritize torque.

Another aspect to think about is environmental conditions. Linear motors may face extreme temperatures, humidity, or dust. Understanding how these factors will affect your system’s reliability is crucial. A poorly chosen motor might lead to increased wear and maintenance costs.

Tip: Evaluate the maintenance requirements. While some systems are low-maintenance, others may require regular checks. This can impact long-term operational costs significantly.

Lastly, budget constraints cannot be overlooked. Different systems come with varying price points. However, the cheapest option may not always serve best in terms of longevity or efficiency. Balancing cost with performance is key.

Evaluating Performance Specifications of Linear Motors

When choosing a linear motor system, evaluating performance specifications is crucial. Understanding specifications like speed, acceleration, and load capacity can make all the difference. A linear motor's speed impacts how quickly tasks are completed. A system that accelerates faster can significantly reduce cycle times. However, not all applications require high speeds. Sometimes, precision is more important than sheer velocity.

Load capacity is another essential aspect. The motor must support the weight of the application while maintaining efficiency. If the load exceeds the motor's capacity, performance suffers. There are cases where users underestimate torque requirements. This can lead to performance issues that are frustrating and costly. Regularly reassessing your needs helps to avoid future complications.

Additionally, cooling methods can influence overall performance. Some linear motors generate heat during operation. This can affect efficiency and longevity. Maintaining optimal temperature is vital. Users often overlook regularly checking cooling systems. Such oversights can lead to inefficient operation. By paying close attention to these specifications, users can make informed decisions that ensure reliable performance throughout the motor's lifespan.

10 Essential Tips for Choosing a Linear Motor System - Evaluating Performance Specifications of Linear Motors

| Specification |

Details |

| Force Output |

Up to 500 N |

| Speed Range |

5 to 3000 mm/s |

| Acceleration |

Up to 30 m/s² |

| Peak Power |

1.5 kW |

| Precision |

±0.01 mm |

| Duty Cycle |

Continuous operation |

| Cooling Method |

Air-cooled |

| Control Type |

Closed-loop control |

| Installation Orientation |

Horizontal/Vertical |

| Environmental Rating |

IP54 |

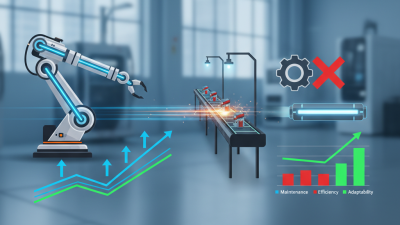

Comparing Different Types of Linear Motor Technologies

When selecting a linear motor system, it's essential to understand the different technologies available. These systems generally fall into three categories: flat, tubular, and rotary. Each type has unique advantages and applications. For instance, flat linear motors are commonly used for high-speed applications, while tubular motors excel in high force density scenarios. According to a recent market analysis by Industry Reports, the demand for linear motors is projected to grow at an annual rate of 8.5% over the next five years.

Within these technologies, performance can vary significantly. For example, flat motors often provide smoother motion. However, they may lack the high force capabilities of their tubular counterparts. Conversely, tubular motors can be more expensive and require precise alignment. Industry data indicates that 25% of companies experience alignment issues during installation. Reflecting on these challenges is crucial when making a decision.

Cost also plays a vital role in choosing the right linear motor system. While tubular systems are powerful, they often come with a higher price tag. Industry experts recommend assessing the total cost of ownership versus initial purchase prices. This can impact long-term operational budgets. Understanding the trade-offs between performance and cost is essential for effective decision-making.

Assessing Cost-Effectiveness and Maintenance of Linear Motor Systems

Choosing a linear motor system is a significant decision that involves assessing cost-effectiveness and maintenance. It's crucial to remember that while the initial investment can be high, long-term cost savings often outweigh these expenses. For instance, a report from the International Society for Automation states that linear motors can reduce energy consumption by up to 40% compared to traditional systems. This can lead to considerable savings over the product's lifecycle.

When evaluating maintenance, consider the wear and tear associated with mechanical components. Non-contact operations in linear motors typically reduce mechanical wear. However, regular checks are still essential. It's suggested that users perform inspections every six months. A lack of maintenance can lead to system failures, which may be costly.

Tip: Ensure you have access to maintenance data. This data can guide your purchasing decision and indicate the reliability of specific models.

Keep in mind that not all linear motors are created equal. Some systems may offer lower upfront costs but require higher maintenance fees. Balancing costs and reliability is key in your selection process. Sometimes, opting for lower-cost solutions leads to expensive repairs in the long term. Prioritize quality and service support when making your choice.