Unlocking Efficiency: How Direct Drive Torque Motors Revolutionize Precision Engineering in Robotics

The field of precision engineering in robotics is undergoing a significant transformation with the advent of direct drive torque motors. A recent report by MarketsandMarkets projects that the direct drive motor market is expected to grow from $7.0 billion in 2021 to $10.5 billion by 2026, at a CAGR of 8.5%. This rapid expansion illustrates the increasing reliance on sophisticated and efficient solutions in high-precision applications across various industries, including manufacturing, aerospace, and medical devices.

Experts in the field have recognized the advantages of direct drive torque motors, with Dr. Emily Johnson, a leading authority in robotics engineering, stating, “The direct drive torque motor technology reduces mechanical complexity, enhances responsiveness, and significantly improves overall system efficiency.” By eliminating the need for gears and belts, these motors provide enhanced control, enabling robotics systems to execute intricate movements with unparalleled accuracy. As the demand for precision increases, the implementation of direct drive torque motors represents a pivotal shift toward optimizing robotic performance and reliability in engineering applications.

The Fundamentals of Direct Drive Torque Motors in Robotics

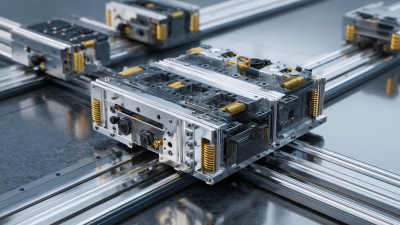

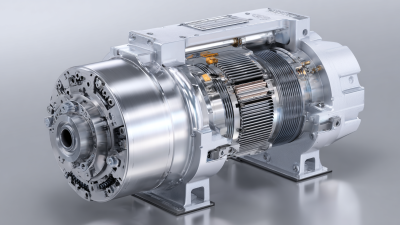

Direct drive torque motors are integral to advancing precision engineering in robotics, providing unprecedented levels of control and efficiency. Unlike traditional motor systems that rely on gearboxes to augment torque, direct drive motors deliver torque directly to the load, eliminating mechanical losses and reducing backlash. This direct transfer of power is crucial for applications requiring high precision, such as robotic arms employed in delicate assembly tasks or humanoid robots mimicking human dexterity.

The role of joint actuators in humanoid robots highlights the importance of these motors. As innovations continue, direct drive torque motors allow for smoother movements and enhanced responsiveness, contributing to more lifelike interactions in robotic systems. The flexibility and compact design of these motors make them suitable for various applications, from autonomous vehicles to advanced manufacturing setups. As precision motion control becomes more critical in robotics, direct drive torque motors are revolutionizing the industry, paving the way for the next generation of intelligent robotic systems.

Unlocking Efficiency: How Direct Drive Torque Motors Revolutionize Precision Engineering in Robotics

| Specification |

Value |

| Torque Output |

1.5 Nm to 600 Nm |

| Speed Range |

0 to 3000 RPM |

| Efficiency |

90% - 95% |

| Control Type |

Feedback Control |

| Weight |

2 kg to 50 kg depending on size |

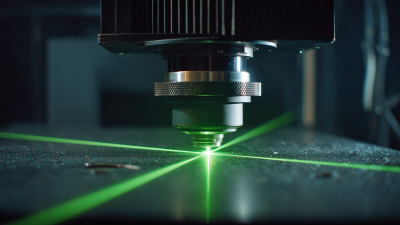

| Applications |

Industrial Robots, CNC Machines, Medical Devices |

| Mounting Style |

External or Face Mounting |

Advantages of Direct Drive Torque Motors Over Traditional Systems

Direct drive torque motors have emerged as a game-changer in precision engineering, particularly in the field of robotics. These motors eliminate the need for gearing systems, providing a direct link between the motor and the load, which significantly enhances performance. According to a recent report by MarketsandMarkets, the direct drive motor market is expected to grow from $3 billion in 2020 to $5.5 billion by 2025, highlighting the increasing reliance on this technology for precise and efficient operation.

One of the primary advantages of direct drive torque motors is their ability to deliver high torque at low speeds without sacrificing precision, making them ideal for applications that require utmost accuracy. Traditional systems often suffer from backlash and mechanical losses due to gears, which can compromise performance. In contrast, direct drive systems boast an impressive efficiency rate of up to 90%, as noted by the International Journal of Advanced Manufacturing Technology.

Tips: When considering the integration of direct drive torque motors, evaluate your application requirements carefully. Look for motors with low cogging torque for smoother operation and reduced noise levels. Additionally, ensure that your control systems are compatible, as advanced control strategies can further enhance motor performance and overall system efficiency.

Applications of Torque Motors in Precision Engineering

Direct drive torque motors are transforming the landscape of precision engineering in robotics by offering exceptional capabilities that enhance performance and accuracy. These motors provide high torque at low speeds, allowing for seamless motion control without the need for gear systems, which can introduce slippage and reduce overall efficiency. In applications requiring intricate movements, such as robotic arms and surgical robots, the direct drive design ensures precise positioning and responsiveness, crucial for tasks that demand meticulous attention to detail.

The versatility of torque motors extends across various domains, from manufacturing automation to medical robotics. In industrial settings, they facilitate advanced assembly processes and improve the speed and reliability of operations. In the medical field, they enable highly accurate and smooth movements in robotic-assisted surgeries, enhancing patient outcomes. The integration of torque motors in precision engineering enables engineers to design systems that are not only more efficient but also capable of executing complex tasks with pinpoint accuracy, making them essential components in the future of robotics.

Challenges and Solutions in Implementing Direct Drive Technology

The implementation of direct drive torque motors in robotics offers significant advancements in precision engineering, yet it is not without challenges. One major obstacle is the need for sophisticated control systems to manage the motors effectively. Traditional servo systems may struggle to provide the instantaneous response and accuracy required by direct drive technology, leading engineers to develop advanced algorithms and feedback mechanisms. These innovations are essential for maintaining desired performance levels, particularly in high-speed applications where even minor deviations can have substantial impacts.

Another challenge stems from the integration of direct drive motors into existing robotic frameworks. Many robotics systems are designed around conventional motors, necessitating structural modifications and potential redesigns for compatibility. This can result in increased costs and extended development timelines. Moreover, thermal management becomes critical, as direct drive motors generate more heat due to their compact size and high torque output. Addressing these issues requires a collaborative approach, bringing together experts in robotics, materials science, and electrical engineering to innovate solutions that enhance performance while streamlining the integration process.

Future Trends in Robotics: The Role of Torque Motors in Automation

The robotics industry is experiencing a significant transformation with the increasing adoption of torque motors, particularly in the realm of automation. With industrial automation now accounting for 70% of gearbox applications, the pivotal role of these motors in robotics, conveyor systems, and manufacturing is unmistakable. A recent report estimates that the robot motor market will reach a value of approximately $13.96 billion by 2024, with projections indicating a compound annual growth rate (CAGR) of 3.8%, growing to nearly $18.92 billion by 2032. This growth is largely fueled by advancements in artificial intelligence and the drive for sustainability in robotic applications.

Tips: When considering the integration of torque motors into your automation processes, it is essential to evaluate specific needs—such as load requirements and speed optimization—to ensure maximum efficiency. Additionally, keeping abreast of technological innovations can provide a competitive advantage in selecting the most suitable motor types for your robotics applications.

As humanoid robots evolve to become integral components of various sectors, understanding the industry trends and dynamics is crucial. The current landscape reveals a robust supply chain that supports not just manufacturing but also research and development. By leveraging these trends, businesses can better position themselves to take advantage of the burgeoning humanoid robot market—projected to grow significantly in the coming years.