How to Choose the Right Fiber Laser Cutting Machine for Your Needs?

Choosing the right fiber laser cutting machine is crucial for modern manufacturing. According to industry expert Dr. Emily Zhao, “Selecting the right machine can greatly impact your production efficiency.” This statement underscores the importance of careful evaluation when exploring options.

Fiber laser cutting machines come in various models and specifications. Whether you need high precision, speed, or flexibility, the right choice depends on your specific requirements. A thorough understanding of your production needs is essential. Many buyers overlook this, leading to mismatches between machine capabilities and production demands.

Consider the materials you will cut and the thickness involved. Not all machines handle every material equally well. Reflect on the long-term implications of your decision. It can lead to improved throughput or unnecessary costs. This is not merely a technical choice but a strategic one. Take time to weigh your options. The right fiber laser cutting machine can transform your operations.

Factors to Consider When Selecting a Fiber Laser Cutting Machine

When selecting a fiber laser cutting machine, several factors come into play. Material type is crucial. Different machines excel at cutting various materials like metal, plastic, or wood. Consider the thickness of the material too. Not all machines can handle heavy-duty tasks. For example, a machine that cuts thin sheets might struggle with thicker ones.

Power and speed are also vital. Machines with higher wattage tend to cut faster and with better precision. However, this can lead to increased energy costs. Check the compromises here. Plus, the operating software matters. User-friendly software can simplify the cutting process and reduce training time. But if it's outdated, efficiency may drop.

Finally, think about maintenance and support. A complex machine can lead to troubles down the road. Regular maintenance is necessary but can be overlooked. Ensure there’s reliable support available. Evaluate the machine's lifespan and parts availability. A long-lasting machine can be more economical. Yet, some users may skip vital checks in this area. Each factor weighs differently based on your specific needs.

Understanding the Different Types of Fiber Laser Technology Available

When selecting a fiber laser cutting machine, understanding the types available is crucial. Fiber laser technology has advanced significantly. The most common types include continuous wave lasers and pulsed lasers. Continuous wave lasers are ideal for thin materials and high-speed cutting. Pulsed lasers perform better with reflective materials. Each type has its applications, depending on the material thickness and type.

Data from industry reports indicate that fiber lasers are becoming increasingly popular due to their efficiency. For instance, fiber lasers can operate at 30% to 50% energy savings compared to traditional systems. This efficiency translates into lower operational costs. However, one must be cautious; not all machines provide the same performance.

Tip: Conduct material tests. Evaluate laser speed and cut quality based on your specific needs.

Also, consider maintenance and support requirements. Some machines may demand more frequent upkeep, affecting overall productivity. There’s a balance to strike between cost and quality. Often, lower-priced models come with hidden trade-offs. Explore all your options and choose wisely.

Tip: Attend industry trade shows. Gaining hands-on experience can clarify your choices.

How to Choose the Right Fiber Laser Cutting Machine for Your Needs?

| Machine Type |

Cutting Capacity |

Power Output |

Speed |

Application |

| Entry-level Fiber Laser |

Up to 10mm |

500W - 1kW |

30 m/min |

Sheet metal cutting |

| Mid-range Fiber Laser |

Up to 20mm |

2kW - 3kW |

60 m/min |

Industrial applications |

| High-power Fiber Laser |

Up to 30mm |

4kW - 10kW |

80 m/min |

Heavy-duty cutting |

| Portable Fiber Laser |

Up to 8mm |

500W - 1kW |

40 m/min |

Small projects & repairs |

| Automated Fiber Laser |

Up to 25mm |

3kW - 6kW |

70 m/min |

Mass production |

Key Features to Look for in a Fiber Laser Cutting Machine

When selecting a fiber laser cutting machine, key features play a crucial role. One significant aspect is the machine's power output. A higher wattage allows for cutting thicker materials and enhances speed. For instance, a machine with 2000W can cut through mild steel up to 8mm thick with precision. In contrast, a lower output may struggle, leading to unsatisfactory results.

Another important feature is the cutting speed. Machines can vary broadly in speed, with some capable of cutting at 20m/min or more. Speed impacts productivity directly. If your workflow demands high-speed cutting, investing in a faster machine makes sense. However, one must consider the trade-off between speed and quality. Too fast can lead to poor edge quality or increased wear on the components.

Finally, the software compatibility is vital. Modern machines often require sophisticated software integration for optimal functionality. Reports indicate that up to 30% of downtime in production can be attributed to software issues. A user-friendly interface can drastically reduce the learning curve. Look for machines that offer good technical support, as this can aid in troubleshooting and maintenance. These considerations are essential for making an informed choice.

Comparative Analysis of Fiber Laser vs. CO2 Laser Cutting Performance

When comparing fiber laser and CO2 laser cutting performance, a few key factors emerge. Fiber lasers excel at cutting metals, offering high precision and speed. They generate a concentrated beam, which allows for cleaner cuts and less wasted material.

On the other hand, CO2 lasers are more versatile when cutting non-metal materials. They can easily handle plastics, wood, and glass.

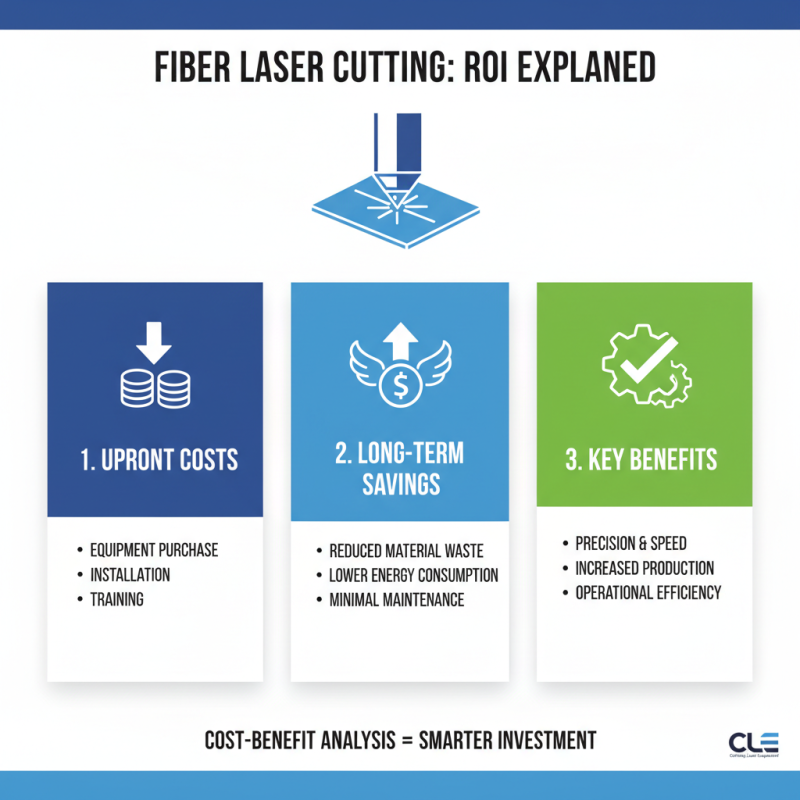

However, fiber lasers are not always the best choice for everyone. Their higher initial investment can be daunting. Also, adapting to maintenance and repair needs might require additional training. Conversely, CO2 lasers may need more frequent tube replacements, which could affect operational costs over time.

In detail, the choice often hinges on specific applications. For instance, if your work focuses primarily on metal, fiber lasers offer clear advantages. Yet, if versatility in materials is essential, CO2 lasers may better meet your needs. Choosing between them should involve careful consideration of your requirements and the nature of your projects.