How to Choose the Right CNC Fiber Laser Cutting Machine for Your Business?

Choosing the right CNC fiber laser cutting machine for your business can feel overwhelming. There are many options available, each with different features and capabilities. Understanding your specific needs is essential before making a decision.

Consider the materials you will be cutting. Different machines handle various materials differently. Are you focusing on metal, plastics, or composites? Each requires a machine optimized for its properties. It's crucial to evaluate the cutting speed and precision you require. A higher speed can improve productivity, while accuracy impacts the quality of the finished product.

Price is another important factor. While a more expensive machine may offer advanced features, it's essential to assess if those features align with your business goals. Sometimes, cheaper options lack necessary capabilities. This decision might require reflection on your long-term plans. Investing in the right CNC fiber laser cutting machine demands careful consideration and understanding of your operational needs.

Understanding Your Business Needs for CNC Fiber Laser Cutting

Understanding your business needs is crucial when selecting a CNC fiber laser cutting machine. Different industries require varied capabilities. For instance, a metal fabrication shop may need faster cutting speeds, while an art studio might prioritize precision and detail. Evaluate the materials you work with regularly. Will the machine handle steel, aluminum, or perhaps acrylic? This will impact your decision.

Tips: Consider your production volume. If your output is high, investing in a powerful machine makes sense. On the other hand, a lower output may allow for a more budget-friendly option. Take time to project future needs. Business growth can change your requirements significantly.

It's easy to overlook service and support. Are you prepared to handle technical issues alone? Some machines come with extensive training and support packages. Assess your team's skill level. Sometimes, investing in training might be necessary, even if the machine is straightforward. Make a list of essential features versus nice-to-haves. Reflect on what you genuinely need. This clarity will help guide your decision.

How to Choose the Right CNC Fiber Laser Cutting Machine for Your Business?

| Criteria |

Description |

Recommended Specifications |

| Material Type |

Determine the types of materials you will be cutting, such as steel, aluminum, or plastic. |

Fiber laser is optimal for metal; CO2 is better for non-metals. |

| Cutting Thickness |

Identify the maximum thickness of material to cut. |

Up to 20mm for mild steel, 10mm for stainless. |

| Bed Size |

Consider the size of sheets you will be using. |

Common sizes: 1300x2500mm, 1500x3000mm. |

| Power Source |

Higher power leads to faster cutting speeds. |

1000W to 3000W typical for industrial use. |

| Budget |

Consider total investment including machine and maintenance costs. |

Typically ranges from $50,000 to $150,000. |

| Support and Service |

Assess the availability of technical support and service options. |

Look for vendors with strong after-sales support. |

Key Features to Consider in CNC Fiber Laser Cutting Machines

When selecting a CNC fiber laser cutting machine, several key features should guide your decision. Power is essential; higher wattage machines cut materials faster and with greater precision. Most businesses find that machines with at least 1000 watts are optimal for metals and other robust materials. According to a recent industry report, companies using machines exceeding 2000 watts have seen production efficiency increase by nearly 30%.

Another critical feature is the cutting area size. Larger machines can process bigger sheets of material without the need for frequent repositioning. This capability reduces setup time. Furthermore, consider the software compatibility. Advanced software enhances productivity by optimizing cut paths. More than 65% of users report significant reductions in waste when using specialized CAD/CAM integration.

Don't overlook the cooling system either. An effective cooling mechanism prolongs the machine's lifespan and maintains cutting quality. However, decisions about aesthetics and accessories can add unnecessary costs. Balance your desires with practical needs. Choosing a machine that fits your business model rather than the latest tech trend is vital. Each feature has trade-offs, and understanding them can lead to a more informed investment.

Evaluating Cutting Speed and Precision for Your Applications

When choosing a CNC fiber laser cutting machine, cutting speed and precision are vital. Speed determines productivity. A faster machine can handle larger workloads. Yet, too much speed can lead to quality issues. Balancing speed with quality is crucial for successful operations.

Precision is equally important. High precision ensures clean, accurate cuts. This reduces waste and saves materials. Different applications may require varied levels of precision. Assess your specific needs carefully. For example, intricate designs demand greater accuracy. Ignoring this can result in costly errors.

Evaluating both factors requires testing. Look for machines that allow sample cuts. Observing results in actual use can reveal potential shortfalls. It’s essential to analyze both speed and precision thoroughly. Identifying flaws in early stages can help avoid larger problems later.

Evaluating Cutting Speed and Precision of CNC Fiber Laser Cutting Machines

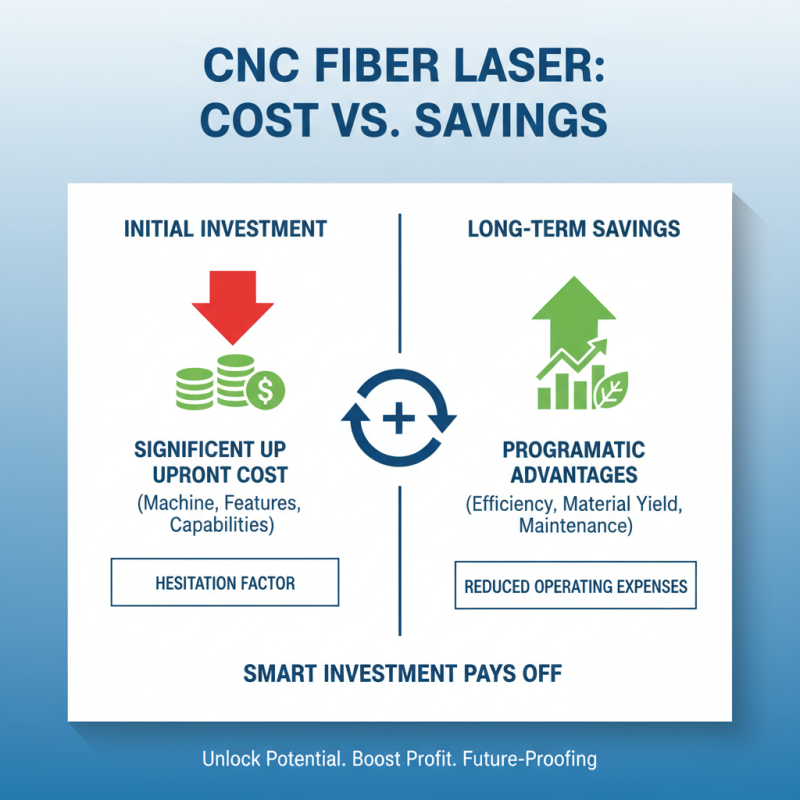

Comparing the Costs: Initial Investment vs. Long-Term Savings

When investing in a CNC fiber laser cutting machine, costs matter. The initial investment can be significant. Prices vary based on features and capabilities. Often, businesses hesitate due to this upfront cost. However, a closer look reveals potential long-term savings that programmatic investments can bring.

Consider maintenance expenses. Some machines require frequent repairs, driving costs up. Others are more durable, offering lower maintenance needs. Efficiency is another crucial element. A machine that cuts faster may seem expensive initially. Yet, the increase in productivity can outweigh the costs over time.

Assess your production needs carefully. A machine that fits specific tasks might seem cheaper but could lead to inefficiencies. Update your understanding regularly. Technology evolves quickly, and what seems costly now might become a budget-friendly option later. Balance these factors extensively before deciding.

Choosing the Right Supplier and Support Services for Your Machine

When selecting the right CNC fiber laser cutting machine, the supplier you choose plays a crucial role. A reliable supplier not only provides quality machines but also offers ongoing support. This support can include training, maintenance, and prompt customer service. Look for suppliers with a good track record. Read reviews and testimonials. A well-established supplier often means better long-term service and reliability.

Tips: Always ask about spare parts availability. This can save you from long downtimes. Check if they have local support options. Timely assistance can keep your operations running smoothly.

Consider the level of technical support provided. Some suppliers may only offer minimal help after the sale. This can lead to challenges when issues arise. It’s vital to understand the warranty options as well. Warranties can vary significantly among suppliers. Ensure you know what is covered. A clear warranty policy indicates the supplier’s confidence in their product.

Tips: Engage with your supplier before purchase. Ask specific questions about their services. A responsive supplier will usually be more beneficial down the line.