2026 How to Choose a Metal Laser Cutting Machine for Home Use?

In recent years, the popularity of the "metal laser cutting machine for home" has surged. Many hobbyists and small businesses seek affordable and efficient options. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $7 billion by 2026, indicating strong growth. However, selecting the right model can be challenging.

Expert Dr. James Parker, a leading figure in laser technology, suggests, "Choosing the right machine requires understanding your specific needs." This insight underscores the importance of assessing factors like power, size, and precision. Many users might underestimate the complexity involved in using these machines effectively. A machine that seems perfect might not align with actual requirements.

Home users often find themselves navigating vast choices. Some may purchase a highly advanced model, only to realize it's unnecessary for their projects. Others might opt for cheaper options that compromise quality. Reflecting on these choices is crucial; the right "metal laser cutting machine for home" can greatly enhance creativity and productivity if chosen wisely.

Choosing the Right Metal Thickness for Laser Cutting Machines at Home

When choosing a metal laser cutting machine for home use, metal thickness is a critical factor. Research indicates that most machines excel at cutting materials ranging from 1mm to 12mm thick. However, cutting beyond this range often leads to issues such as incomplete cuts or excessive heat generation. For many hobbyists, materials like aluminum or stainless steel are common choices. They can effectively be cut at thicknesses of 3-5mm, balancing ease of use with quality results.

Understanding the limitations of your equipment is essential. Machines may struggle with thicker materials. Thick cuts may require multiple passes, sacrificing precision. A recent industry report noted that 30% of users encounter difficulties when cutting metals thicker than they are equipped for. Being aware of your machine’s capabilities helps avoid frustration. Frequent adjustments may be needed based on the metal type.

Experimenting with various thicknesses can lead to unexpected outcomes. You might get uneven edges or burnt finishes. These imperfections can be learning points. Consider testing different settings with scrap materials before working on your project. This approach cultivates a better understanding of what’s achievable while also minimizing waste. Embrace the learning curve and adjust your practices as necessary.

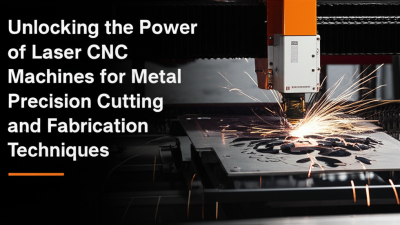

Understanding the Different Types of Metal Laser Cutting Technologies Available

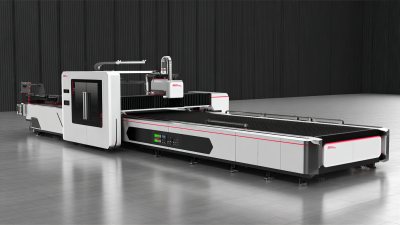

When choosing a metal laser cutting machine for home use, understanding the different technologies is key. Three main types dominate the market: fiber lasers, CO2 lasers, and hybrid systems.

Fiber lasers excel in cutting thin metals with high precision. They’re fast and energy-efficient. CO2 lasers work well on thicker materials. They are versatile but might need more maintenance. Hybrid systems combine features of both, offering flexibility but at a higher cost.

Consider these tips when selecting a machine. Look for user-friendly software to simplify your work. Choose a machine that fits your available space. Ensure it supports various metal types. Research safety features, especially ventilation systems.

A common mistake is not assessing your needs correctly. Some users buy machines that are too advanced for simple projects. Reflect on your goals before purchasing. A basic model might serve you well, while complex tasks may require enhanced technology.

Evaluating the Power and Speed Requirements for Home Use Laser Cutters

When choosing a metal laser cutting machine for home use, power and speed are vital. The right power level ensures efficient cutting of various materials. A machine with adjustable power settings can adapt to different tasks. Higher wattage means faster cuts, but it may not be necessary for all projects.

Speed is another crucial factor. Faster cutting reduces project time, but it can sacrifice precision. Some homeowners may prefer slower speeds for intricate designs. The ideal machine balances both speed and detail. It’s important to consider the thickness of the materials you plan to cut.

Tips: Evaluate your typical projects. Consider the materials you often use. Think about both your short and long-term needs. A machine with too much power might not be cost-effective. A lower-powered option could work perfectly for your home workshop. Always read user reviews and tips to better understand specific models. Assess your willingness to learn and adjust settings, as this can influence your choice.

2026 Metal Laser Cutting Machine Power and Speed Comparison

Comparing Costs: Budgeting for a Metal Laser Cutting Machine for Home Use

When budgeting for a metal laser cutting machine for home use, costs can vary significantly. Entry-level models can start around $2,000, while more advanced machines may exceed $10,000. According to industry reports, the average cost across models tends to be between $5,000 and $8,000. This wide range makes it essential for users to determine their specific needs.

Before purchasing, assess your cutting requirements. If you work with thinner materials, a lower-powered laser is suitable. For thicker metals, invest in a higher wattage machine. Additionally, consider operational costs such as electricity, maintenance, and safety equipment. These can add up over time, influencing your budget.

**Tip:** Research financing options or second-hand machines. These can help lower initial expenses. Always include delivery and installation costs in your budget planning to avoid surprises. Balancing your budget with quality is key. Choose wisely to ensure your investment lasts. Reflecting on your choices can lead to better decisions.