How to Choose the Best Steel Laser Cutter for Your Needs?

Choosing the right steel laser cutter can be a daunting task. There are many factors to consider. Your projects' requirements will shape your decision significantly.

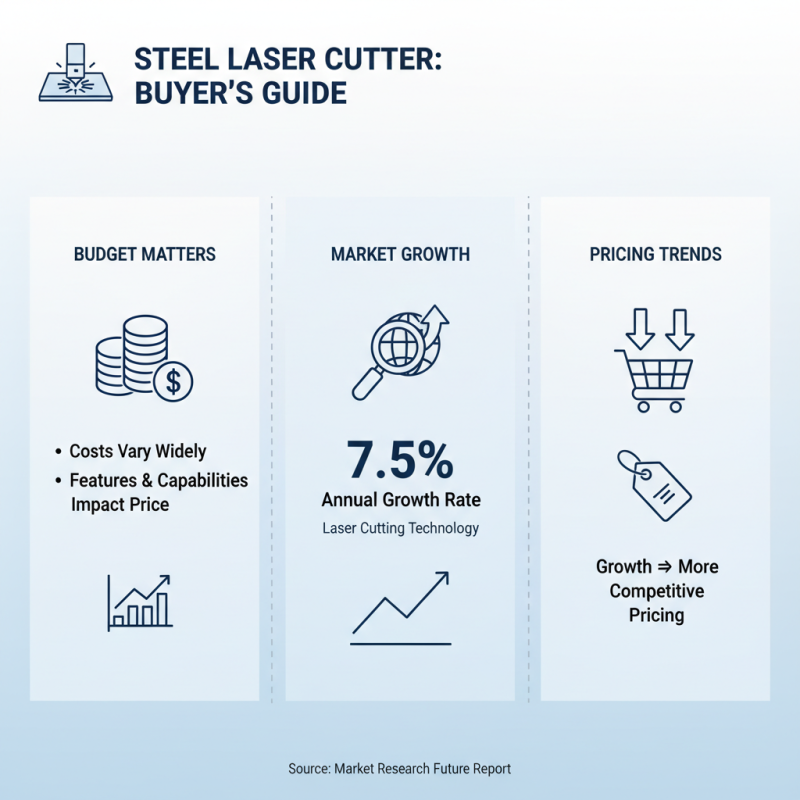

You need a machine that fits your needs. Think about the thickness of the steel you will cut. Each cutter has its limits. Consider the speed and precision necessary for your operations. Some machines boast high speed but might lack accuracy. In contrast, others may excel in detail but fall short on speed. Price is another crucial element. High-end machines may not always be the best for your specific use.

Take the time to research. Read user reviews and compare models. Consider the after-sales support offered. A reliable steel laser cutter should come with solid service options. Reflect on how often you will use the machine. Quality and efficiency are more important than flashy features. Each decision plays a role in your satisfaction and productivity.

Understanding the Basics of Steel Laser Cutting Technology

Steel laser cutting technology has revolutionized the manufacturing industry. This process uses focused laser beams to cut through steel with precision. It offers enhanced accuracy, making it ideal for complex designs. The ability to cut intricate shapes is a significant advantage over traditional methods. This means less material wastage and more efficient production.

Understanding the basics of this technology is crucial before making a purchase. Factors such as laser type and cutting speed play a vital role in performance. CO2 lasers are popular for their cost-effectiveness, while fiber lasers excel in speed and efficiency. However, the choice ultimately depends on your specific needs. Consider the thickness of the steel and the desired finish.

It's essential to evaluate your workspace and budget as well. Sometimes, a less powerful machine can meet your requirements perfectly. Not every project demands the latest technology. Reflect on these factors, as they will guide your decision-making process.

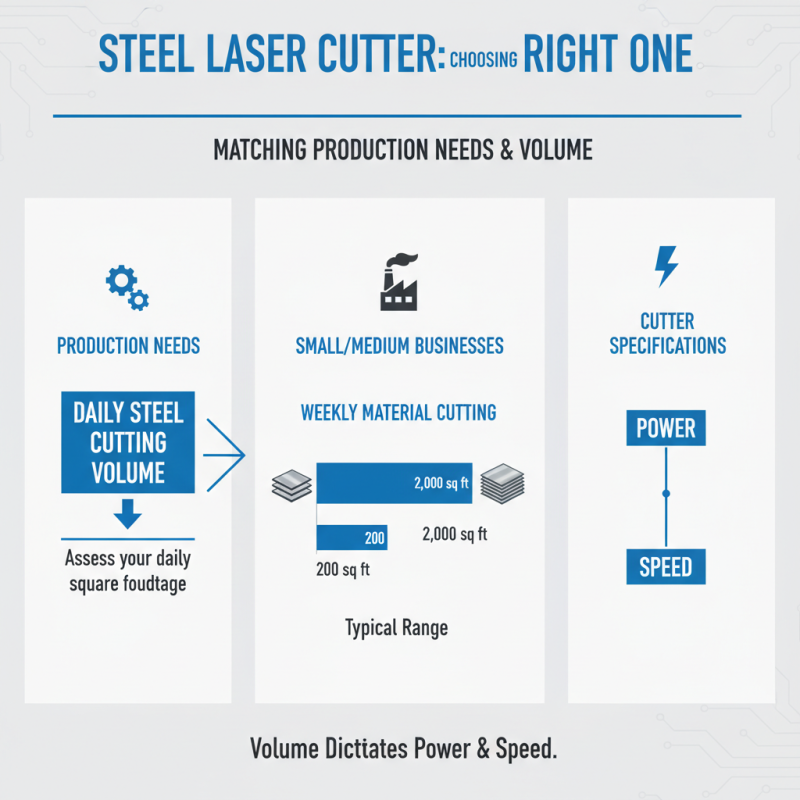

Assessing Your Production Needs and Volume Requirements

When choosing a steel laser cutter, production needs and volume requirements are crucial. Understanding your production demands starts with assessing how much steel you will cut daily. Reports indicate that many small to medium businesses cut between 200 to 2,000 square feet of material weekly. That range can dictate the cutter's power and speed.

Higher volume operations may require a more robust machine. For instance, a shop cutting 1,000 square feet daily likely needs a cutter with a higher wattage to maintain efficiency. However, choosing a machine with too high a capacity can lead to underutilization. It's vital to balance power with actual output. If a machine is underused, it may increase operational costs without providing benefits.

Consider the thickness of steel and types of jobs as well. A study showed that 60% of users switch to a different thickness based on production needs. This fluctuation can impact the choice of laser cutter. Assess and reflect on your specific volumes and types of cuts required. This nuances your decision-making and leads to investments that match actual application.

Key Features to Consider When Selecting a Laser Cutter

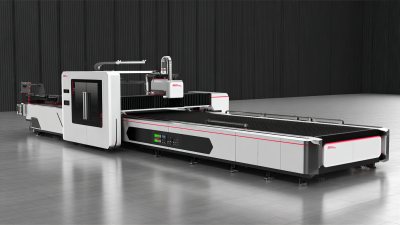

When selecting a steel laser cutter, there are several key features to consider. The power of the laser is crucial. Higher wattage usually means faster cutting speeds and greater efficiency. According to industry reports, a 1000W CO2 laser cutter can cut through materials up to 19mm thick. Conversely, lower wattage options struggle with thicker materials, impacting productivity.

Another critical aspect is the cutting area. A larger bed size allows for more versatility. It enables users to work on larger pieces without frequent repositioning. Reports reveal that businesses often underestimate the importance of sufficient space. This limitation can lead to wasted time and increased costs.

Additionally, consider the machine's cutting speed and precision. If the speed is too slow, it can affect overall workflow. However, very high speeds can compromise accuracy. Finding the right balance is essential. Some manufacturers boast cutting speeds up to 400 inches per minute, but not all achieve precision at those rates. Thus, it's vital to assess user reviews and test performance in real-world settings.

Comparing Different Types of Steel Laser Cutters

When considering the best steel laser cutter for your needs, several types are available. Each type offers unique features and capabilities. For instance, CO2 laser cutters are popular for their efficiency and versatility. They excel in cutting thicker steel and are often used in various industries. However, they may struggle with very intricate designs.

Fiber laser cutters, on the other hand, are known for their precision and speed. They provide cleaner cuts and can handle reflective materials well. Yet, they might not be as effective for thick steel compared to CO2 lasers. Each option has its strengths and weaknesses, making your requirements essential in the decision-making process.

It's also crucial to evaluate the level of maintenance each type requires. Fiber lasers might demand less frequent maintenance, while CO2 lasers could need more regular checks. This factor can affect your overall operational costs. Consider not only the initial investment but also how each type aligns with your production needs. Weigh the pros and cons carefully, and make an informed choice.