How to Choose the Right Linear Motor Drive for Your Application

In the rapidly evolving field of automation and motion control, selecting the appropriate linear motor drive for your specific application has become a crucial decision faced by engineers and designers alike. According to Dr. James Thompson, a leading expert in linear motion technology, "The right linear motor drive can significantly enhance performance and efficiency, bridging the gap between innovation and application." This statement underscores the importance of carefully evaluating both the technical specifications and operational requirements of your project.

With an array of options available in the market, understanding the fundamental principles of linear motor drives—along with their capabilities and limitations—can empower you to make an informed choice. These drives are known for their precision, speed, and responsiveness, making them ideal for various applications, from robotics to industrial automation. Moreover, the focus on energy efficiency and compact design continues to push the boundaries of what linear motor drives can achieve.

As we delve into the nuances of selecting the right linear motor drive, we will explore key considerations such as load characteristics, motion profiles, and environmental factors that impact performance. By aligning your selection process with these critical elements, you can ensure that your linear motor drive will not only meet the immediate needs of your application but will also serve as a reliable foundation for future advancements.

Understanding Linear Motor Drives and Their Applications

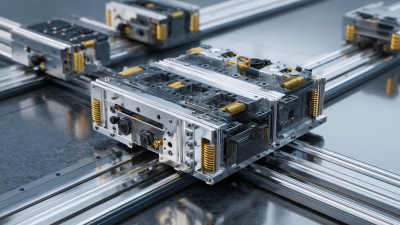

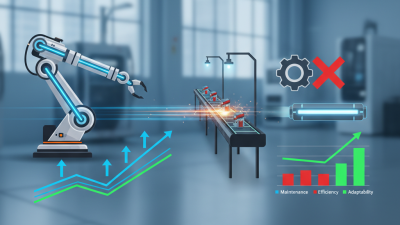

Linear motor drives have emerged as a pivotal technology in various industries due to their high efficiency and precision in motion control. These drives operate on electromagnetic principles, providing direct linear motion without the need for mechanical transmission elements, which can lead to significant reductions in maintenance and operational costs. According to a recent industry report by MarketsandMarkets, the linear motion system market is projected to reach $7.9 billion by 2025, reflecting an increasing trend towards automation and the adoption of advanced manufacturing technologies.

Applications of linear motor drives are vast and diverse, spanning sectors such as robotics, packaging, and semiconductor manufacturing. In robotics, for example, linear motors enable precise movement and positioning, which is crucial for tasks requiring high accuracy, such as assembly or inspection operations. Furthermore, linear drives are increasingly being utilized in high-speed applications, such as conveyor systems and automated guided vehicles, where both speed and precision are of utmost importance. A report from ResearchAndMarkets highlights that the demand for linear motor technologies is expected to grow at a CAGR of 9.2% from 2023 to 2030, mainly credited to their advantages in speed, efficiency, and minimal wear compared to traditional systems.

Understanding the distinctive characteristics of linear motor drives is crucial for selecting the right system for any application. Factors such as force requirements, speed profiles, and system integration capabilities play critical roles in determining the most suitable linear motor solution. As industries continue to innovate and automation becomes more prevalent, the demand for tailored linear motor solutions that meet specific application needs will only grow, making it essential for engineers and project managers to stay informed about advancements in this technology.

How to Choose the Right Linear Motor Drive for Your Application

| Application Type |

Motor Type |

Max Force (N) |

Speed (m/s) |

Precision (mm) |

Environment |

| Pick and Place Automation |

Iron Core Linear Motor |

120 |

3.5 |

0.1 |

Clean Room |

| CNC Machines |

Slotless Linear Motor |

200 |

4.0 |

0.05 |

Industrial |

| Material Handling |

Direct Drive Linear Motor |

150 |

2.5 |

0.2 |

Warehouse |

| Robotics |

High-Power Linear Motor |

250 |

5.0 |

0.03 |

Outdoor |

| Semiconductor Manufacturing |

Flat Linear Motor |

100 |

2.0 |

0.01 |

Ultra clean |

Key Considerations When Selecting a Linear Motor Drive

When selecting a linear motor drive for your application, several key considerations come into play. First, you need to define the specific requirements of your system. This includes factors such as the load weight, speed requirements, and precision needed for your application. Understanding the operational environment is also crucial, as temperature fluctuations, dust, and moisture can impact performance.

Tip: Always calculate the maximum and minimum load conditions your drive will experience. This will help in selecting a motor that not only meets but exceeds your basic requirements, ensuring longevity and reliability in your operations.

Another important aspect is the type of linear motor drive technology that fits your needs best. Different technologies, such as direct drive versus screw-driven systems, come with their own advantages and trade-offs in terms of efficiency, complexity, and maintenance. Evaluating compatibility with your existing systems, including controllers and sensors, is essential for smooth integration and functionality.

Tip: Consider modular designs that allow for upgrades and modifications in the future. This flexibility can save time and reduce costs when requirements change over the lifespan of your equipment.

Evaluating Performance Specifications of Linear Motor Drives

When evaluating performance specifications of linear motor drives, the first aspect to consider is the motor's force and speed ratings. The maximum force indicates the load the motor can handle effectively, while the speed rating represents how fast it can operate without losing precision. These specifications are crucial in determining whether a linear motor drive can meet the demands of specific applications, such as precision machining or assembly lines where speed and accuracy are paramount.

Another important factor to analyze is the inertia and responsiveness of the motor drive. The inertia affects how quickly the motor can accelerate and decelerate, impacting cycle times in high-speed applications. Additionally, the responsiveness is linked to the control algorithms employed in the drive system, influencing its ability to adapt to varying loads or commands. A thorough examination of these specifications ensures that the selected linear motor drive will deliver optimal performance, tailored to the operational requirements of the application at hand.

Performance Comparison of Linear Motor Drives

Assessing Environmental and Installation Requirements

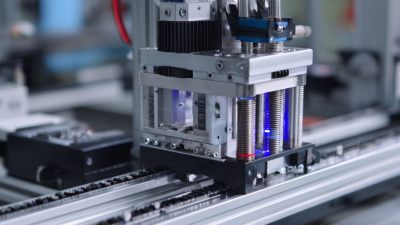

When selecting a linear motor drive for a specific application, it is crucial to assess the environmental and installation requirements to ensure optimal performance and longevity. Begin by examining the environmental factors, such as temperature ranges, humidity levels, and exposure to dust or chemicals. Linear motors may operate in diverse conditions, from clean rooms to harsh industrial environments. Choosing a drive that can withstand these parameters will not only enhance reliability but will also reduce the risk of premature failure.

Installation requirements are equally important in the selection process. Consider the available space and possible configurations for mounting the linear motor drive. A compact design may be necessary for tight spaces, while larger systems might require robust support structures. Additionally, ensure that the motor’s power supply and control systems are compatible with the existing infrastructure. Proper alignment and installation techniques will contribute significantly to the system’s efficiency and accuracy, further emphasizing the need for thorough planning in relation to the environment and installation specifics.

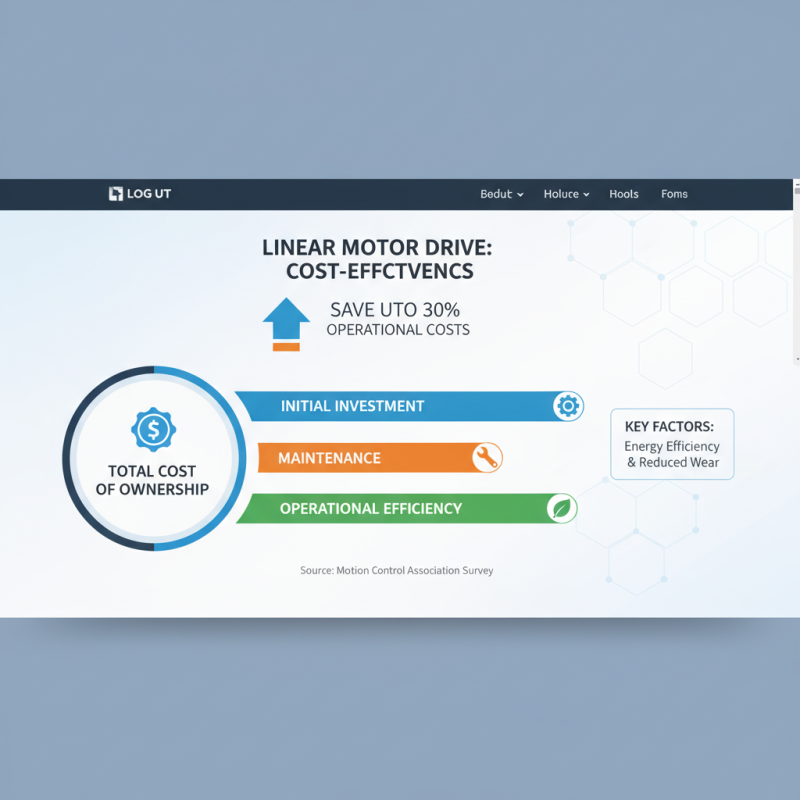

Budgeting and Cost-Effectiveness in Linear Motor Drive Selection

When selecting a linear motor drive, budgeting and cost-effectiveness play crucial roles in the decision-making process. According to industry reports, the total cost of ownership for linear motor drives can vary significantly based on initial investment, maintenance, and operational efficiency. A survey by the Motion Control Association indicates that companies can save up to 30% in operational costs by choosing the right motor drive system, primarily through enhanced energy efficiency and reduced wear and tear.

Tips for maintaining budget efficiency include conducting a thorough needs analysis before making a purchase. Understanding your application requirements, such as load capacity and speed, can prevent overspending on unnecessary features. Additionally, consider the life cycle costs associated with different models. Some linear motor drives, while higher in initial cost, offer greater durability and lower maintenance fees, ultimately resulting in lower total expenditures over time.

Another critical aspect is to evaluate the scalability of the linear motor drive. Investing in a versatile system can accommodate future growth and technological advancements, reducing the need for frequent replacements. Research from the Robotics Industry Association suggests that businesses that prioritize upgradable systems report a 25% rise in productivity, emphasizing the importance of making cost-effective choices that align with long-term operational goals.