How to Choose the Right Direct Drive Linear Motor for Your Application

In recent years, the demand for efficient motion control solutions has surged across various industries, prompting an increased interest in direct drive linear motors. These innovative devices eliminate traditional mechanical components, offering enhanced precision, reduced maintenance, and improved performance. According to a report by Research and Markets, the global direct drive motor market is projected to reach $8.5 billion by 2025, driven by advancements in automation and the growing need for high-speed and high-accuracy applications. As manufacturers look to optimize their systems, understanding how to choose the right direct drive linear motor for specific applications becomes crucial.

Selecting the appropriate direct drive linear motor involves analyzing several key factors, including load requirements, speed, acceleration, and the operational environment. The ability of these motors to deliver high acceleration and precise positioning is paramount in sectors such as robotics, semiconductor manufacturing, and medical equipment. Another industry report highlights that direct drive linear motors exhibit efficiency rates exceeding 90%, further positioning them as a vital component in cutting-edge technology. As companies aim to enhance productivity and maintain competitiveness, mastering the selection process for direct drive linear motors is essential for achieving optimal operational outcomes.

Understanding Direct Drive Linear Motors: Basics and Benefits

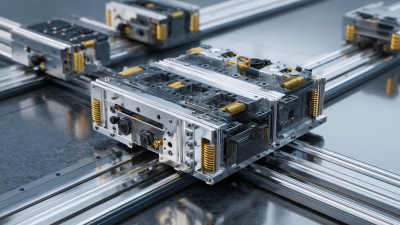

Direct drive linear motors represent a significant advancement in motion control technology, providing a direct conversion of electrical energy into linear motion. Unlike traditional systems that rely on gears and mechanical linkages, these motors utilize magnetic forces to produce movement, enabling smoother and more efficient operation. This technology eliminates backlash and mechanical wear, resulting in higher precision and reduced maintenance requirements. The straightforward design of direct drive linear motors also allows for faster response times, making them ideal for applications that require rapid movements and quick positioning.

The benefits of direct drive linear motors extend beyond just performance. Their simplicity reduces the complexity of the overall system, allowing for easier integration and installation in various industrial applications. Additionally, they offer increased reliability due to fewer moving parts, which leads to longer lifespans and lower operational costs. Implementing direct drive linear motors can lead to significant energy savings, as they operate with higher efficiency compared to traditional drive systems. Understanding these fundamentals and advantages is crucial for selecting the right motor that aligns with specific operational requirements and desired outcomes.

Key Factors to Consider When Selecting a Direct Drive Linear Motor

When selecting a direct drive linear motor for your application, several key factors should be considered to ensure optimal performance and longevity. First and foremost, understanding the load requirements is critical. According to a recent industry report by Research and Markets, the increasing demand for precision in automation has led to a significant rise in direct drive linear motor usage, with a projected market growth of over 10% annually through 2026. Evaluating factors such as weight, speed, and force needed for your specific application will influence not only the motor selection but also the system design.

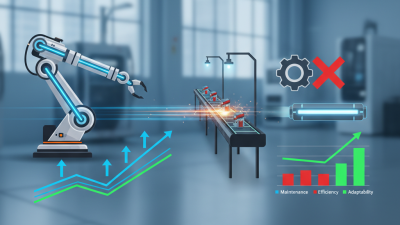

Another essential consideration is the environmental conditions in which the motor will operate. Many industries, including manufacturing and robotics, often require motors that can withstand extreme temperatures, humidity, and dust. The same study highlighted that motors designed for harsh environments can enhance system reliability, reducing maintenance costs by as much as 20%. Finally, the ease of integration with existing systems and the required control mechanisms should not be overlooked. Motors that come with user-friendly interfaces and robust support for various control methods can streamline implementation, ultimately improving operational efficiency.

Evaluating the Performance Requirements for Your Application

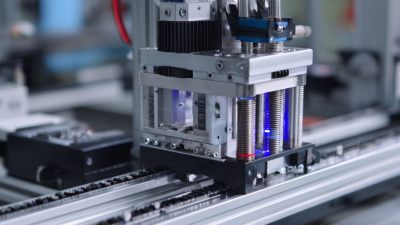

When selecting a direct drive linear motor, the first step is to clearly evaluate the performance requirements specific to your application. This involves understanding the load specifications, including weight and dimensions, as well as the expected speed and acceleration.

Different applications demand varied performance characteristics; for instance, high-speed pick-and-place operations might require motors that can achieve rapid acceleration without sacrificing precision, while precision cutting applications may need motors with minimal backlash and exceptional positional accuracy.

Additionally, consider the operating environment where the motor will be deployed. Factors such as temperature fluctuations, humidity levels, and exposure to contaminants can greatly influence the motor's suitability and longevity. High-performance applications may also necessitate motors with enhanced cooling solutions or more robust materials to withstand challenging conditions.

By thoroughly assessing these performance requirements, you can ensure that you select a direct drive linear motor that not only meets your immediate needs but also delivers reliability and efficiency over the long term.

Comparing Different Types of Direct Drive Linear Motors

When selecting a direct drive linear motor for a specific application, it is crucial to understand the different types available, as each has its unique advantages and suitability for various industrial tasks. Direct drive linear motors come in several types: single-sided, double-sided, and tubular designs. According to a report by Grand View Research, the global linear motors market is projected to reach $6.91 billion by 2025, showcasing the increasing adoption of these technologies in automation and robotics sectors.

Single-sided motors are popular for applications requiring simpler designs and lower costs, making them ideal for less demanding tasks. In contrast, double-sided motors offer higher force density and compact profiles, making them suitable for high-performance applications like CNC machinery and high-speed pick-and-place tasks. Tubular motors, although less common, provide unique motion capabilities and can be particularly effective in specialized transportation systems, as indicated by a study from Mordor Intelligence, which notes their rising demand in automotive and aerospace sectors.

When comparing these types, consider the key specifications such as thrust, stroke length, and acceleration. For instance, a recent study from Industry Research Company highlights that direct drive linear motors can achieve acceleration rates exceeding 100 m/s², which is significantly higher than traditional rotary systems. This performance advantage is critical in applications where speed and precision are paramount, ultimately driving efficiency and productivity in various manufacturing settings. Understanding these distinctions can lead to the selection of the optimal direct drive linear motor that meets specific operational requirements.

Common Applications of Direct Drive Linear Motors in Industry

Direct drive linear motors are increasingly utilized in various industrial applications due to their unique advantages, including high precision and efficiency. One common application is in automated assembly systems, where these motors enable rapid movement and positioning of components. Their direct drive mechanism eliminates the need for gears or belts, resulting in reduced maintenance costs and improved reliability. This makes them ideal for tasks requiring precise and repeatable linear motion, such as in electronics manufacturing and automotive assembly lines.

Another notable application of direct drive linear motors is in packaging solutions. Industries that require high-speed packaging operations benefit from the swift and smooth motion provided by these motors. They ensure that products are handled with care while maintaining high throughput rates. Additionally, their compact design allows for flexibility in machine layout and configuration, making it easier for manufacturers to optimize their production lines. As companies strive to enhance productivity and maintain quality standards, the role of direct drive linear motors in sectors such as food processing and pharmaceutical packaging continues to expand.