How to Choose a Metal Laser Cutting Machine for Home Use?

Choosing the right metal laser cutting machine for home use can be challenging. Expert Jane Doe emphasizes, "A well-chosen machine can elevate your projects." This advice is crucial in a market filled with options.

When selecting a metal laser cutting machine for home, consider your specific needs. Think about the types of materials you plan to cut. Make a list of the necessary features. The right specifications can significantly impact your work’s quality.

Don't overlook the importance of size and space. A compact machine might be ideal for a home garage. However, larger models may offer more capabilities. Reflect on your workspace and future projects when making this decision. A thoughtful approach can guide you to the most suitable choice.

Factors to Consider When Selecting a Metal Laser Cutting Machine

Choosing the right metal laser cutting machine for home use involves several key factors. One important aspect is the power output. Machines typically range from 40W to 150W for residential applications. Higher wattage allows for cutting thicker materials more efficiently. A study by Industry Research showed that machines with at least 100W are preferred for versatility. They can handle various metals, including aluminum and stainless steel, which are common in home projects.

Another crucial consideration is the size of the machine. Compact models are ideal for small workspaces. However, larger machines provide more cutting area, which increases project possibilities. For instance, a machine with a cutting bed of 24"x36" offers ample space for most home projects. But, measuring your workspace is vital. If the machine is too big, it could disrupt your work area.

Finally, the software compatibility is essential. Many machines come with user-friendly software, but understanding its capabilities is vital. Some software allows for advanced designs, while others may be limited. Review user feedback to gauge effectiveness. A 2022 report noted that machines with intuitive software saw higher customer satisfaction. Balancing all these factors can lead to a well-informed purchase.

Comparison of CO2 vs. Fiber Laser Cutters for Home Use

Choosing a metal laser cutting machine for home use can be daunting.

CO2 and fiber laser cutters each have their own strengths and weaknesses.

CO2 lasers are versatile and handle various materials well. They excel in cutting non-metal materials, too.

However, they may not be the best choice for thick metals. Fiber lasers are powerful for cutting metals. They deliver high-speed cutting and long-term durability.

However, they might be more expensive upfront.

When deciding between these options, consider your projects. If you plan to cut mostly metals, a fiber laser is ideal. For diverse material needs,

CO2 might serve you better. Think about the intensity of your usage. Beginners could start with CO2 lasers since they are easier to operate.

Tips: Ensure the machine fits your workspace. Laser cutters can be large and heavy.

So, measure your area properly. Also, think about the ease of maintenance. Some machines require more care than others.

Your choice should align with your skill level and future projects. Keep in mind that both options have their quirks.

Finding the right balance of features is crucial.

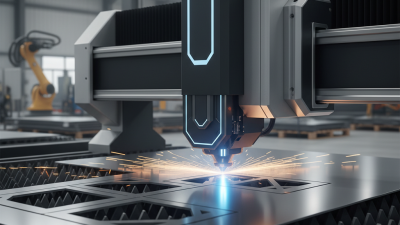

Understanding Power Ratings and Their Impact on Cutting Performance

When selecting a metal laser cutting machine for home use, understanding power ratings is essential. Power ratings, measured in watts, directly affect cutting performance. A higher wattage generally means better cutting capability. For example, machines with 100-150 watts can cut thin sheets easily, while those over 300 watts handle thicker materials better. Data from industry reports show that machines with at least 150 watts can cut steel up to 5 mm thick effectively.

Tips: Consider your material types. Aluminum, steel, and copper behave differently under laser cutting. Also, be mindful of how the wattage influences cutting speed. A higher watt machine may cut faster, but it can also lead to heat distortion. Finding the right balance is crucial.

Keep in mind that not all home settings need high-powered machines. Sometimes, a 100-watt machine suffices for hobbyists. But if you're looking at serious projects, investing in a more powerful machine may be worthwhile. Remember, care and maintenance also play a key role in sustaining performance over time. Regular cleaning and checking for wear can prevent costly repairs down the line.

Evaluating Size and Portability for Home Workspace Limitations

When selecting a metal laser cutting machine for home use, size and portability are crucial. Many hobbyists work in limited spaces. A compact machine fits better in a garage or small workshop. Think about dimensions. Make sure it can be easily stored when not in use. A machine that takes up too much space could become a burden.

Portability is another factor to consider. A heavier machine might offer more durability but can restrict movement. Lighter models could make it easier to transport. This is important if you want to move it for various projects. However, you might sacrifice stability with smaller machines. Reflect on your workspace layout. Will the machine adapt to your needs?

Evaluate your projects. Will you often cut large pieces of metal? If so, a larger machine may be necessary. On the other hand, small projects benefit from a compact design. Balancing size, portability, and project demands can be challenging. It’s essential to think ahead, learning from each choice made.

Budgeting for Metal Laser Cutting Machines: Costs and Maintenance Expenses

When budgeting for metal laser cutting machines, it's crucial to understand the total cost. The machine itself can range widely in price. Entry-level options may seem affordable. However, high-quality machines often require a larger investment. Remember, cheap tools may lead to higher long-term costs.

Maintenance expenses can also add up. Regular upkeep is essential for optimal performance. Costs include replacing parts and routine servicing. Factor in these expenses when planning your budget. Be realistic about your use and needs. Don't overspend on features you may not utilize.

Tips: Consider local repair services before buying. This helps avoid hefty shipping costs for maintenance. Always research before making a decision. Explore used machines as an alternative option. Make sure to assess their condition thoroughly. Your choices can define your long-term satisfaction with the machine.

Metal Laser Cutting Machine Costs and Maintenance Expenses