Why Choose a Linear Motor Controller for Your Next Automation Project

In the realm of modern automation, the choice of control systems is critical to enhancing efficiency and precision in various applications. Among these, the linear motor controller stands out as a pivotal component for driving linear motion systems. This technology offers several advantages, such as high-speed performance, precise positioning, and reduced mechanical complexity, which can significantly benefit automation projects across diverse industries. By opting for a linear motor controller, engineers and project managers can ensure better performance and reliability, ultimately leading to increased productivity and reduced maintenance costs.

The evolution of automation technology has highlighted the need for more sophisticated control solutions. Traditional motor systems often encounter limitations in speed and accuracy, which are crucial in high-performance environments. In contrast, linear motor controllers utilize cutting-edge technology to optimize motion control, making them an ideal choice for robotic arms, conveyor systems, and CNC machinery. Their seamless integration into existing workflows enables businesses to take advantage of enhanced operational efficiencies while maintaining flexibility and scalability in their automation processes.

Choosing a linear motor controller for your next automation project is more than just selecting a component; it is a strategic decision that can impact the overall success of your operations. Understanding the substantial benefits that these controllers offer can lead to advancements in innovation and competitive advantage within your sector. As industries continue to evolve, embracing linear motor control technology may be the key to unlocking new potential in automation.

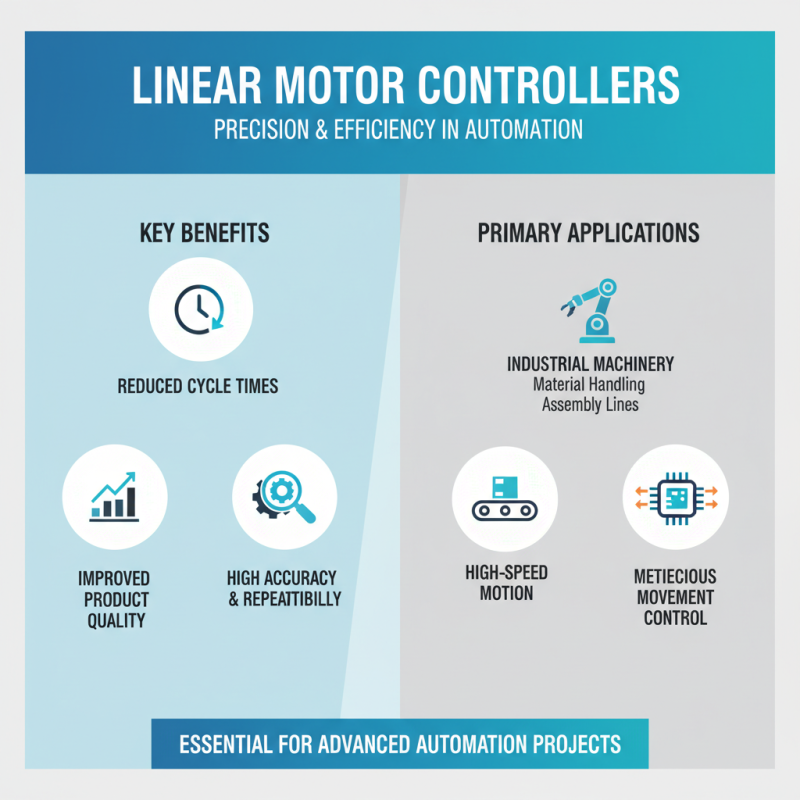

Understanding Linear Motor Controllers: Key Features and Benefits

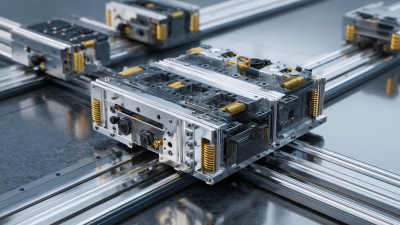

Linear motor controllers are increasingly becoming a preferred choice in automation projects due to their precise motion control capabilities and efficiency. A linear motor controller provides direct drive systems which eliminate mechanical components such as belts or gears, resulting in reduced friction and wear. According to a report by Allied Market Research, the global linear motion systems market is projected to reach $7.2 billion by 2025, driven by the increasing demand for automation in manufacturing and warehousing processes. This shift underscores the advantages these controllers bring to various applications, from robotics to material handling.

One of the key features of linear motor controllers is their ability to deliver high acceleration and velocity with minimal latency. This capability is particularly beneficial in environments requiring rapid positioning, as evidenced by a study published by Research and Markets, which found that systems employing linear motors can achieve positioning accuracy up to 1 micron. Additionally, linear motor controllers often come equipped with advanced feedback systems, ensuring optimal performance and reliability. Their suitability for cleanroom environments further enhances their appeal, as they can minimize contamination risks associated with traditional drive mechanisms. As industries continue to prioritize efficiency and accuracy, the role of linear motor controllers in automation becomes ever more crucial.

Applications of Linear Motor Controllers in Automation Projects

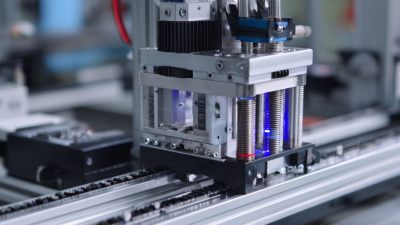

Linear motor controllers are becoming increasingly essential in various automation projects, thanks to their precision and efficiency. One prominent application is in industrial machinery, where they facilitate high-speed motion and accuracy in tasks such as material handling and assembly lines. By utilizing linear motors, manufacturers can reduce cycle times and improve product quality, making these controllers ideal for any application requiring meticulous control over movement.

Moreover, linear motor controllers are widely used in healthcare automation. For instance, they can be employed in medical imaging devices, such as MRI machines, where precise positioning is critical for obtaining accurate scans. In laboratory automation, linear motors help in automating the process of sample handling and preparation, significantly enhancing throughput while minimizing human error. As industries continue to seek more efficient and reliable solutions, the application of linear motor controllers is expected to expand, further transforming automation landscapes across sectors.

Comparative Analysis: Linear Motor Controllers vs. Traditional Controllers

When considering automation projects, the choice between linear motor controllers and traditional controllers significantly impacts performance and efficiency. Linear motor controllers offer a direct form of actuation, allowing for precise control of motion without the need for mechanical transmission systems, such as gears or belts. This results in reduced mechanical wear and tear, leading to lower maintenance costs and longer operational lifespans. In contrast, traditional controllers, which often rely on rotary motors, introduce complexity by requiring additional components to convert rotary motion to linear motion. This not only reduces efficiency but can also lead to increased energy consumption due to friction and slippage.

In terms of response time and speed, linear motor controllers excel. They provide instantaneous motion response, which is particularly advantageous in applications requiring high-speed operations and quick positioning. Consequently, tasks that involve repetitive movements can be executed with minimal lag, enhancing throughput in production environments. Traditional controllers, while effective in many applications, may struggle with this level of responsiveness, often experiencing delays caused by their reliance on intermediary mechanical components. This difference highlights the growing preference for linear motor controllers in modern automation projects, especially where precision and speed are critical considerations.

Choosing the Right Linear Motor Controller for Your Specific Needs

When selecting a linear motor controller for your automation project, it's essential to consider the specific requirements of your application. Different projects can vary greatly in terms of speed, precision, load capacity, and the environment in which they operate. Therefore, assessing these factors is paramount to choosing a controller that can deliver the desired performance. For instance, if your project demands high-speed motion or precise positioning, a controller with advanced feedback mechanisms and higher processing capabilities will be more suitable.

Moreover, understanding the communication protocols required for your system can significantly impact your decision. Many linear motor controllers offer compatibility with various communication interfaces, such as Ethernet or RS-232, which can enhance integration with existing systems. Additionally, considering the controller's adaptability to different types of linear motors, such as direct drive or ball screw systems, can ensure better coordination and efficiency in your automation setup. By thoroughly analyzing these aspects, you can select a linear motor controller that aligns perfectly with your automation objectives.

Why Choose a Linear Motor Controller for Your Next Automation Project

| Feature |

Linear Motor Controller |

Benefits |

| High Precision |

Positioning accuracy of ±0.01 mm |

Ideal for applications requiring tight tolerances |

| High Speed |

Speeds up to 5 m/s |

Enhances productivity and throughputs |

| Compact Design |

Space-saving installation |

Easier integration into limited spaces |

| Energy Efficiency |

Low power consumption |

Reduced operational costs |

| Versatility |

Compatible with various systems |

Adaptable to different automation needs |

Future Trends in Linear Motor Technology and Automation Integration

As automation technology continues to evolve, the integration of linear motor systems is becoming increasingly significant. These systems offer unparalleled precision and speed, making them ideal for various applications in manufacturing and robotics. The future of linear motor technology is set to enhance automation processes through greater efficiency and reduced maintenance requirements. As industries push for more streamlined operations, the demand for linear motors is anticipated to grow, leading to innovations that focus on better performance and interoperability with other automation systems.

Looking ahead, the latest trends suggest an increased focus on smart technology integration within linear motor setups. The incorporation of IoT (Internet of Things) capabilities will allow for real-time monitoring and control, helping to optimize productivity and reduce downtime. Furthermore, advancements in AI and machine learning will pave the way for predictive maintenance, enabling systems to identify potential issues before they arise. This synergy of linear motor technology with automation tools appears to set the stage for a more responsive and adaptive manufacturing environment, which could redefine operational standards across various sectors.