How to Choose the Best Home Laser Cutter Machine for Your DIY Projects

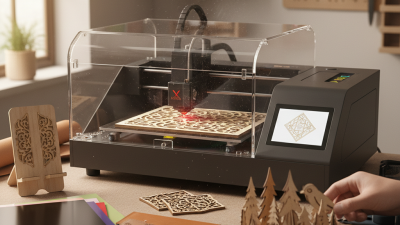

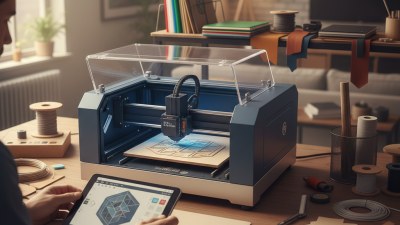

When embarking on DIY projects, having the right tools can make all the difference. One of the most versatile and powerful tools you can invest in is a home laser cutter machine. These machines have revolutionized the crafting and fabrication landscape, allowing hobbyists and creators to achieve precise and intricate designs with ease. Whether you're working on woodworking projects, creating custom signs, or even producing intricate decorative items, a home laser cutter machine can elevate your work to a professional level.

Choosing the best home laser cutter machine requires careful consideration of several factors, including the type of materials you plan to cut, the size of your projects, and your budget. With various models and features available, understanding what works for your specific needs is essential. This guide will walk you through the key aspects to help you select the ideal machine that aligns with your DIY aspirations, ensuring that your creativity knows no bounds. From understanding key specifications to evaluating ease of use, this article aims to equip you with the knowledge necessary to make an informed decision.

Understanding the Basics of Home Laser Cutter Machines

When considering a home laser cutter machine for DIY projects, it’s essential to understand the foundational aspects of these devices. Laser cutters utilize a high-powered laser beam to precisely cut or engrave materials, making them ideal for work with wood, acrylic, and even fabrics. This technology operates by focusing light into a fine point, allowing for high accuracy and intricate designs that traditional cutting tools often cannot achieve. According to a report from MarketsandMarkets, the global laser cutting market is expected to reach $5.15 billion by 2026, indicating a significant rise in adoption across various sectors, including home users.

Key features to examine when selecting a home laser cutter include the power output (measured in watts), the size of the cutting area, and the types of materials it can handle. Machines with higher wattage can cut through thicker materials more efficiently and are often recommended for projects that require deeper cuts. Additionally, a larger cutting area facilitates the creation of bigger designs without the need for multiple passes, which can be a considerable advantage for DIY projects. According to a survey by Statista, around 27% of users believe that material versatility is a critical factor in their purchasing decision, thus emphasizing the importance of choosing a machine that can accommodate a range of materials for diverse project needs.

Key Features to Consider When Selecting a Laser Cutter

When selecting a home laser cutter machine for your DIY projects, it’s vital to consider a few key features that will significantly influence your crafting experience. First, the power of the laser cutter is a crucial factor, typically measured in watts. For instance, a laser cutter with a power range of 40-100 watts is generally suitable for most home projects, allowing you to cut through materials like wood, acrylic, and leather efficiently. According to a market analysis report by Grand View Research, the demand for laser cutting technology is expected to grow at a CAGR of 6.9% from 2021 to 2028, highlighting its increasing integration into homes and workshops.

Another important feature to evaluate is the bed size. A larger workspace enables the handling of bigger projects without the need for multiple cuts, thus improving workflow efficiency. Additionally, look for the type of focus mode – adjustable focus allows for sharper cuts whereas fixed focus is convenient for smaller projects. Typically, machines with larger bed sizes (around 600x400mm) are favored among DIY enthusiasts, as they allow for versatility in project sizes.

Tips: Always research the materials you plan to use with your laser cutter, as some machines are better suited for specific materials. Additionally, consider the software compatibility with your computer; many machines offer unique software that enhances usability and project creation. Finally, always check for customer reviews to ensure that the machine meets your needs and has a reputation for reliability and ease of use.

Comparison of Key Features in Home Laser Cutters

Comparing Different Types of Laser Cutting Technologies

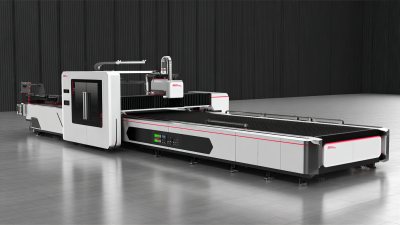

Laser cutting technology has revolutionized the way DIY enthusiasts approach projects, offering precision and versatility across numerous materials. When evaluating different types of laser cutting technologies, one should consider CO2, fiber, and diode lasers, each catering to distinct needs within the DIY community. According to a report by the International Laser Display Association, CO2 lasers dominate the market for non-metal cutting applications, particularly because they can efficiently handle materials like wood, acrylic, and textiles. These lasers operate effectively at a wavelength of 10.6 micrometers, making them ideal for engraving and cutting a wide variety of materials.

Conversely, fiber lasers, operating at a wavelength of around 1.06 micrometers, are highly effective for metalworking, offering faster processing times and higher energy efficiency compared to their CO2 counterparts. The market for fiber laser cutting systems is projected to grow significantly, with a compound annual growth rate (CAGR) of 8.5% from 2021 to 2026, as per market research from TechSci Research. This growth can be attributed to the increasing demands of metal fabrication in DIY projects, which require both speed and precision in cutting. For those involved in intricate design work, understanding these differences facilitates informed decisions, enhancing the overall efficacy and outcome of DIY laser cutting projects.

How to Choose the Best Home Laser Cutter Machine for Your DIY Projects

| Laser Cutting Technology |

Suitable Materials |

Cutting Thickness |

Precision |

Cost Range |

| CO2 Laser |

Wood, Acrylic, Leather, Fabric |

Up to 20 mm |

High |

$200 - $5000 |

| Fiber Laser |

Metal, Acrylic, Plastics |

Up to 8 mm |

Very High |

$300 - $10000 |

| Diode Laser |

Wood, Paper, Thin Plastics |

Up to 5 mm |

Moderate |

$100 - $1000 |

| YAG Laser |

Metal, Ceramics, Glass |

Up to 10 mm |

High |

$500 - $20000 |

Budgeting for Your Home Laser Cutter: Costs and Value

When considering a home laser cutter for your DIY projects, budgeting becomes an essential component of the decision-making process. The initial cost of a laser cutter can vary significantly based on its specifications, capabilities, and features. Basic models can start at a few hundred dollars, while more advanced machines may cost several thousand. It’s vital to identify the scope of your projects to determine the appropriate investment. A lower-priced machine might suffice for simple tasks, whereas intricate designs or thicker materials may necessitate a higher-end option.

In addition to the purchase price, ongoing operating costs must also be factored into your budget. This includes maintenance, replacement parts, and consumables such as laser tubes and protective gear. Moreover, it’s wise to consider the potential value a laser cutter can bring to your DIY ventures. By investing in a quality machine, you can create customized items, engage in crafting, or even start a small business from home. Thus, weigh the costs against the long-term benefits, and ensure that you are making a financially sound decision that aligns with your creative ambitions.

Tips for Maintenance and Safety Practices with Laser Cutters

When working with home laser cutters, maintenance and safety practices are crucial to ensure both optimal performance and user protection. According to industry reports, nearly 30% of laser cutter malfunctions result from improper maintenance. Regularly cleaning the lens and mirrors not only enhances cutting efficiency but also prolongs the lifespan of the machine. It is recommended to use specialized lens cleaning solutions with a soft lint-free cloth to avoid scratches.

Safety should be at the forefront when operating laser cutters. Essential tips include ensuring adequate ventilation, as fumes and particles can be generated during the cutting process. Additionally, wearing appropriate safety gear—such as goggles specifically designed to filter out the wavelength of the laser being used—can protect your eyes from potential damage. Furthermore, having a fire extinguisher nearby and being aware of the machine's emergency shut-off procedures can provide an added layer of safety.

Lastly, understanding the materials you are working with is vital. Some materials may release toxic fumes when cut and should be avoided or handled with extreme caution. The lack of proper knowledge about material compatibility with laser cutters is often highlighted as a common pitfall by experts, stressing the importance of thorough research and planning before beginning any DIY project. By prioritizing maintenance and adhering to safety practices, users can greatly enhance both productivity and safety while utilizing laser cutting technology.