Top 10 Best Laser Cutting Machines for Precision and Performance?

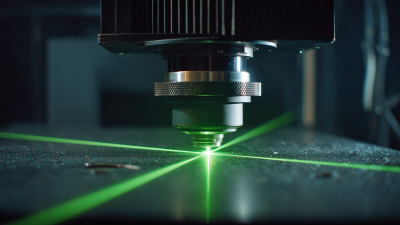

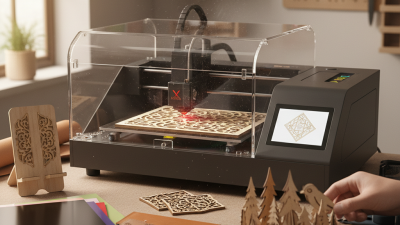

In the world of manufacturing and crafting, the laser cutting machine stands out for its precision. This tool has revolutionized how creators approach materials, whether metal, wood, or acrylic. The power and finesse of a top-quality laser cutting machine can elevate projects from ordinary to extraordinary.

However, choosing the right laser cutting machine is challenging. The market is flooded with options, each promising unmatched performance. For beginners and professionals alike, understanding the best choices is crucial to achieving desirable results. From speed to accuracy, different machines offer unique advantages and drawbacks.

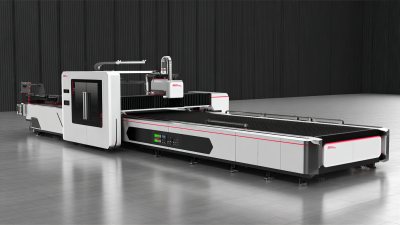

Investing in a laser cutting machine is not just about the initial purchase. Maintenance and operational costs can add up quickly. It's essential to reflect on these aspects before making a decision. The right machine should meet not only immediate project needs but also long-term goals. Exploring the top 10 best laser cutting machines can provide insight into making a thoughtful and informed choice.

Top Trends in Laser Cutting Technology for Enhanced Precision

Laser cutting technology is evolving rapidly. Enhanced precision is at the forefront of these advancements. Recent industry reports indicate that the global laser cutting market is projected to reach $4.2 billion by 2025. This growth is driven by the demand for precision cutting in various sectors, including automotive and aerospace.

One significant trend is the adoption of fiber lasers over traditional CO2 lasers. Fiber lasers offer better efficiency and lower operational costs. They can cut through thicker materials with greater accuracy. Industry experts cite that fiber lasers improve cutting speeds by nearly 25% compared to older technologies. However, the initial investment can be high, which may deter smaller businesses from upgrading.

Another trend is the integration of AI and automation in laser cutting machines. These technologies promise to enhance the precision and speed of operations. Reports suggest that automation can reduce errors by up to 40%. Yet, companies might struggle with the transition, as workforce training is crucial for utilizing these advancements effectively. Embracing technology presents challenges, but the potential for improved performance is significant.

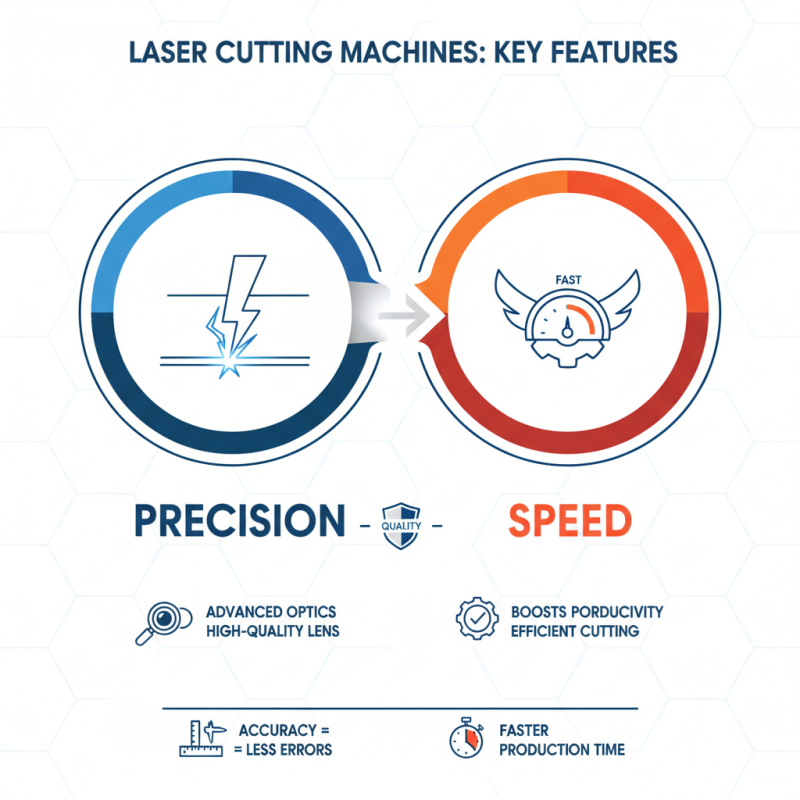

Key Features to Look for in High-Performance Laser Cutting Machines

When searching for high-performance laser cutting machines, certain features stand out. Precision is non-negotiable. Look for machines with advanced optics that provide sharp and clear cuts. A high-quality lens can significantly enhance accuracy, reducing the chance of errors. Cutting speed also matters. A faster machine can boost productivity, but speed shouldn't sacrifice quality.

Another key aspect is the control system. User-friendly interfaces make operation smoother. Machines that offer software compatibility provide flexibility in design adjustments. Enhanced cooling systems prevent overheating during long cuts. Moreover, adaptability to various materials expands the machine’s usefulness. Consider if it can handle wood, metal, or acrylic effectively.

Finally, ensure the machine has reliable safety features. Emergency stops and proper enclosures protect the user. Although many machines claim high performance, some may not deliver consistently. Research is crucial. Understanding the pros and cons of each feature helps in making informed decisions. Look for reviews and testimonials to see real-world performance. It’s essential to weigh your specific needs against available options.

Comparative Analysis of CO2 and Fiber Laser Cutting Systems

When considering laser cutting systems, CO2 and fiber lasers each have unique strengths. CO2 lasers excel in cutting non-metal materials. They are effective on plastics, wood, and fabrics. Their ability to deliver smooth cuts is impressive. However, the focus on thicker materials can sometimes lead to slower processing speeds. Users should note the downtime for maintenance. This can affect productivity in busy work environments.

On the other hand, fiber lasers shine when working with metals. Their efficiency saves both time and energy. They can cut through materials like stainless steel and aluminum with precision. However, they may fall short when cutting thicker non-metal materials. Operators must adjust their techniques accordingly. It’s essential to evaluate the specific needs of a project. Sometimes, a mixed approach using both systems can yield the best results. Finding the right balance is crucial, as each laser type presents its own set of challenges and benefits.

Top 10 Best Laser Cutting Machines for Precision and Performance

| Model |

Type |

Laser Power (W) |

Max Cutting Thickness (mm) |

Speed (mm/s) |

Precision (mm) |

| Model A |

CO2 |

150 |

20 |

800 |

0.01 |

| Model B |

Fiber |

300 |

15 |

1000 |

0.02 |

| Model C |

CO2 |

100 |

10 |

600 |

0.03 |

| Model D |

Fiber |

500 |

25 |

1200 |

0.01 |

| Model E |

CO2 |

200 |

18 |

750 |

0.015 |

| Model F |

Fiber |

700 |

30 |

1500 |

0.005 |

| Model G |

CO2 |

80 |

8 |

500 |

0.04 |

| Model H |

Fiber |

600 |

28 |

1400 |

0.008 |

| Model I |

CO2 |

180 |

22 |

700 |

0.02 |

| Model J |

Fiber |

400 |

21 |

1100 |

0.007 |

The Impact of Laser Wattage on Cutting Speed and Quality

The wattage of a laser cutting machine significantly influences both cutting speed and quality. Higher wattage means more energy, which usually leads to faster cuts through thicker materials. For example, a 150-watt laser can easily slice through metal plates, while a 40-watt laser may struggle with even thin sheets. This difference in capability can impact your efficiency and project deadlines.

However, wattage isn't the only factor to consider. Material type, thickness, and desired finish all play crucial roles as well. For instance, a high-wattage laser might create rough edges on delicate materials. Finding the right balance is key. Some operators find their machines underperforming due to poorly matched settings. Adjusting speed and focus can also affect outcomes. Everyone must experiment and refine their approach.

Often, users overlook the importance of maintenance. A well-maintained machine can yield better results, regardless of wattage. Dust and debris on lenses can sharply reduce cutting quality. This raises questions about your setup and habits. Are you doing everything necessary to achieve optimal performance? Even high-wattage lasers require regular checks. Embracing this ongoing practice leads to more precise results and greater satisfaction.

Top 10 Best Laser Cutting Machines for Precision and Performance

This chart illustrates the impact of laser wattage on cutting speed and quality for various laser cutting machines. The data reflects how increased wattage correlates with improved cutting speed and overall performance in laser cutting applications.

Industry Applications of Laser Cutting: A Focus on Materials and Finishes

Laser cutting technology has found diverse applications across various industries. It excels in precision and speed. From automotive components to intricate jewelry pieces, laser cutters work wonders on different materials. According to a recent industry report, the global laser cutting market is projected to reach $6.7 billion by 2026. Such growth reflects its importance in manufacturing processes.

When it comes to materials, laser cutting adapts well to metals, plastics, and wood. The ability to create detailed finishes is remarkable. Manufacturers benefit from reduced waste and lower operational costs. However, challenges persist. For instance, selecting the right machine for specific materials remains critical. Operators must understand various thicknesses and types, as each requires different settings.

Surface finishes greatly influence product quality. A recent study indicated that 28% of users reported dissatisfaction due to subpar cut quality. Choosing the right laser technology can mitigate these issues. While advancements are impressive, consistency is essential. Ongoing training for operators could enhance efficiency and output quality. Evaluating and refining techniques will ensure better results over time.