Top 5 Best Etel Linear Motors for Precision Automation?

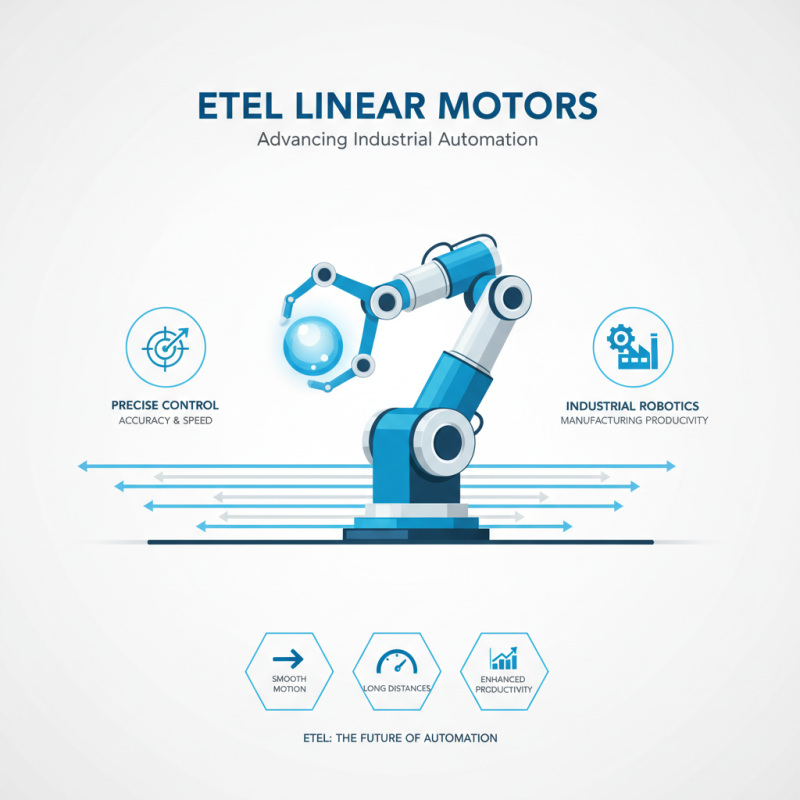

In the realm of precision automation, choosing the right equipment is vital. The etel linear motor stands out for its reliability and precision. Many industries rely on these motors for their machinery and robotics. They provide exceptional control over movement, enhancing productivity.

Automation demands high performance. However, not every etel linear motor fits all applications. Understanding specific needs is crucial when selecting a motor. Factors like speed, load capacity, and precision all play a role. Mistakes in this process can be costly.

Exploring the top five etel linear motors reveals their unique features. Each motor offers benefits for various applications. But, there are trade-offs to consider. Price and compatibility can affect the decision. A thoughtful approach can yield the best outcomes for automation projects.

Key Features of Etel Linear Motors for Precision Automation

When evaluating linear motors for precision automation, several key features come into play. The ability to deliver high accuracy is paramount. These motors provide consistent positioning, often achieving less than a micron of deviation. This precision is crucial in applications such as semiconductor manufacturing and robotics.

Speed is another important aspect. Etel linear motors can reach impressive speeds, which enhances productivity. Yet, sometimes achieving rapid acceleration may cause mechanical stress. It's vital to balance speed with stability for optimal performance. Compact design also matters. Smaller motors take up less space and are easier to integrate. However, a compact design can lead to overheating issues if not properly managed.

Additionally, ease of control is essential. Advanced control systems allow for smooth operation, reducing vibration and wear. This leads to longer service life. However, the complexity of the control system can sometimes be a hurdle. Users must invest time to master the technology to fully utilize it. Achieving the perfect alignment of these features can be challenging, but it results in improved efficiency and precision.

Top 5 Best Etel Linear Motors for Precision Automation

| Model |

Max Speed (m/s) |

Force (N) |

Stroke Length (mm) |

Precision (µm) |

| Model A |

3.5 |

120 |

200 |

5 |

| Model B |

4.0 |

150 |

250 |

3 |

| Model C |

5.0 |

100 |

150 |

1 |

| Model D |

3.0 |

130 |

180 |

4 |

| Model E |

2.5 |

110 |

220 |

2 |

Factors to Consider When Selecting an Etel Linear Motor

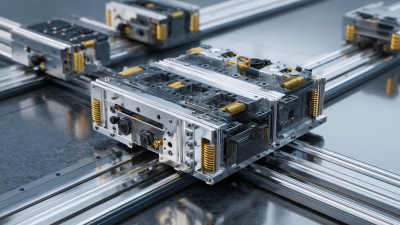

When selecting an Etel linear motor for precision automation, several key factors come into play. One crucial aspect is the motor's force output. A report by the International Journal of Advanced Manufacturing Technology indicates that motors that provide consistent force are essential for accurate positioning in high-speed applications. Often, a motor that can deliver more than 100 N of continuous force is preferred for heavy-duty tasks.

Another important consideration is the motor's speed capabilities. According to market analysis data, motors capable of exceeding 2 m/s in speed lead to improved efficiency in production lines. This increased speed must be balanced with precision, as higher speeds can sometimes result in decreased accuracy. The ideal solution requires careful calibration and testing to find the best operational parameters.

Thermal management is also vital. Motors generate heat, affecting performance. As reported in the IEEE Transactions on Industrial Electronics, maintaining optimal operating temperatures can prevent performance drops. Selecting motors with effective cooling systems, like forced air or liquid cooling, can enhance reliability. However, this creates complexity in design. Each design choice warrants reflection on trade-offs between simplicity and performance.

Top 5 Best Etel Linear Motors for Precision Automation

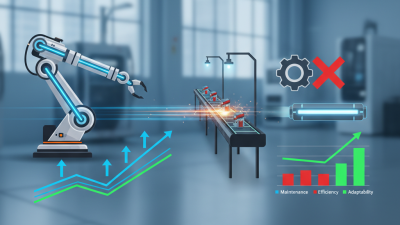

This chart illustrates the key performance metrics of the top 5 linear motors based on force output, speed, and resolution, which are critical factors in precision automation applications.

Future Trends in Etel Linear Motor Technology and Precision Automation

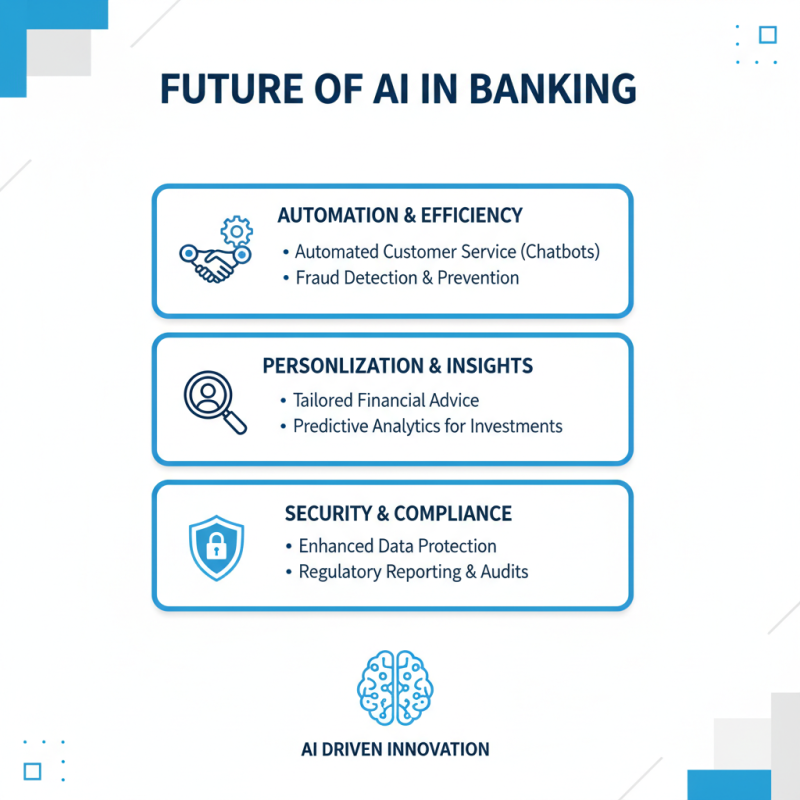

The landscape of precision automation is evolving rapidly. As industries demand higher accuracy, Etel linear motors are gaining traction. Recent reports indicate the linear motor market is expected to reach USD 3.1 billion by 2025, with a CAGR of over 6%. This growth reflects the increasing need for refined automation solutions in manufacturing and robotics.

New advancements in Etel linear motor technology focus on enhancing performance and reducing energy consumption. These motors are designed for low friction and minimal maintenance, which is crucial for long-term sustainability. Many industries are investing more heavily in automation to boost efficiency, yet some manufacturers still hesitate to fully adopt these technologies. They worry about potential disruptions during the transition phase.

Additionally, the shift towards greener technologies impacts linear motor development. There's a growing expectation for electric systems to replace traditional mechanical drives. Industry studies suggest that electric drives can enhance energy efficiency by up to 30%. However, the initial investment might seem daunting. This creates a significant gap between technological potential and practical implementation, prompting a need for careful assessment in various sectors.