Top 10 Benefits of Using a Metal Laser Cutter for Your Projects?

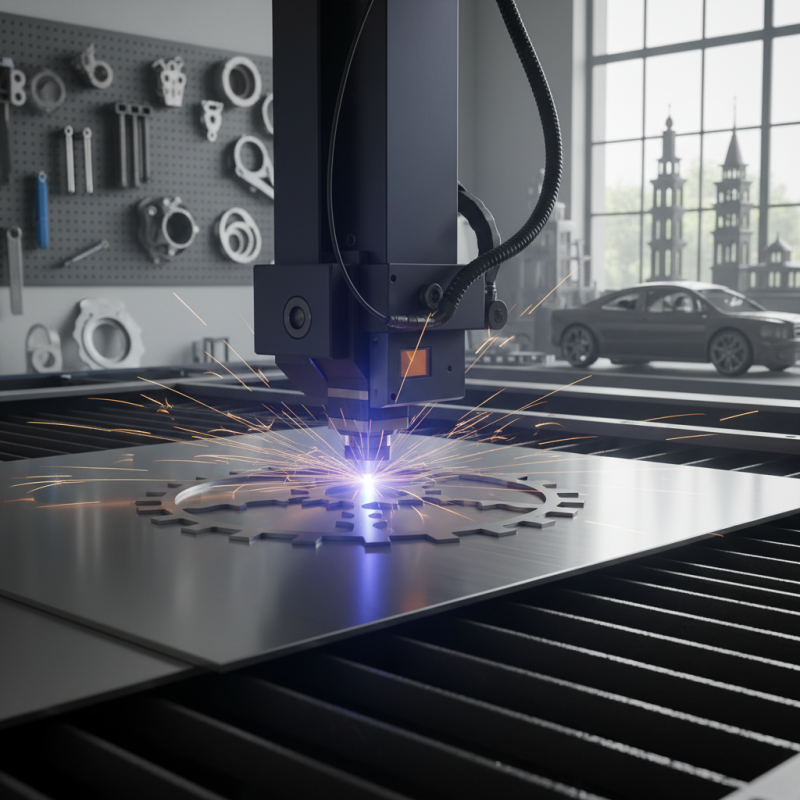

In recent years, the metal laser cutter has transformed various industries. This innovative tool offers precision and efficiency. It's not just for professionals; hobbyists find value too. From intricate designs to robust components, this technology meets diverse needs.

The benefits of using a metal laser cutter are numerous. With its ability to cut through thick materials, it saves time and enhances productivity. Projects that once took hours can now be completed in a fraction of the time. However, users must be cautious. The initial cost can be high for those starting out.

Additionally, mastering the software can be challenging. Not everyone finds it easy to operate. Yet, with practice, the results often outweigh these hurdles. The quality of work produced is often superior to that of traditional cutting methods. Exploring these top benefits can help you understand why a metal laser cutter is worth considering for your next project.

Benefits of Precision Cutting: Enhancing Accuracy with Metal Laser Cutters

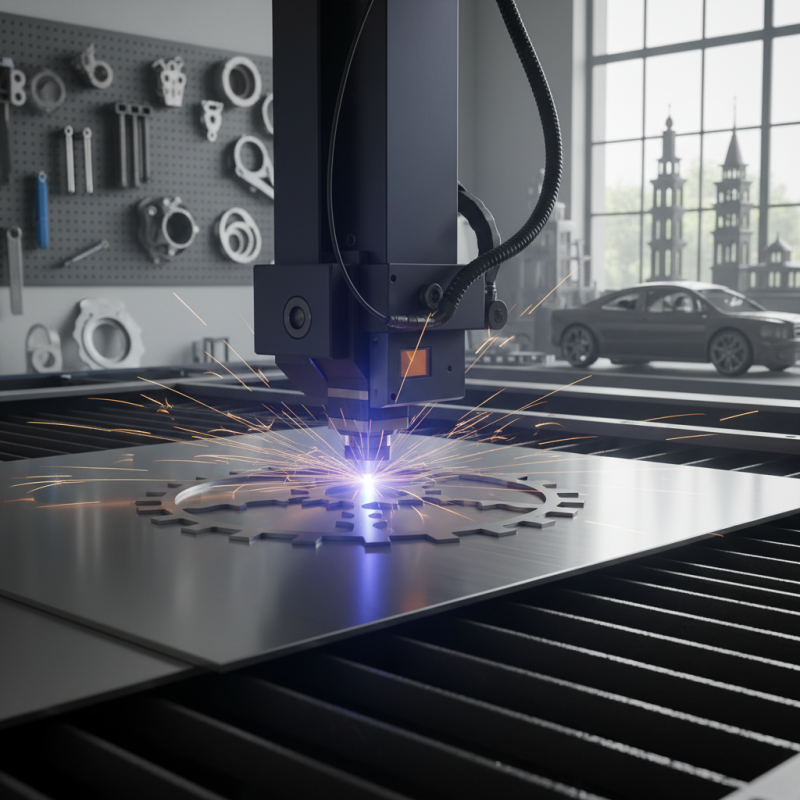

Metal laser cutters have revolutionized the manufacturing sector. Precision is one of their most significant benefits. Unlike traditional cutting methods, laser cutting can achieve tolerances as tight as ±0.01 mm. This high level of accuracy helps prevent material waste. A study by the Fabricators & Manufacturers Association highlighted that accuracy reduces rework costs by up to 30%.

The technology behind laser cutting allows for intricate designs and complex shapes. For industries such as aerospace and automotive, this precision is crucial. When complex parts are cut accurately, they fit together perfectly during assembly. This factor streamlines the production process and enhances overall efficiency. Researchers found that improved accuracy in metal cutting processes can yield up to 20% faster production times.

However, challenges still exist. The initial cost of metal laser cutters can be high. Additionally, the skill level required to operate them is significant. Not every worker can quickly adjust settings for various materials and thicknesses. Training is essential but can require time and resources. Addressing these issues is key to fully reaping the benefits of laser cutting technology.

Top 10 Benefits of Using a Metal Laser Cutter for Your Projects

Cost Efficiency: Analyzing the Economic Impact of Laser Cutting Technology

Laser cutting technology has transformed manufacturing. It's economical and efficient. Analyzing the financial impact reveals significant savings. These machines reduce material waste. They provide precision cuts that minimize errors. This results in less time spent on rework.

Using a metal laser cutter also saves on labor costs. Fewer workers are needed to achieve high outputs. Automation is key here. Quick setups and minimal maintenance requirements make it even more appealing. However, initial costs may be high. It's crucial to weigh long-term benefits against upfront investments.

Tip: Choose a model that suits your project size. Not every laser cutter fits every task. Think about future projects, not just the current one.

Tip: Maintain your laser cutter regularly. This prevents costly repairs down the line. Even small issues can lead to significant downtime.

Speed and Efficiency: Comparing Production Rates of Laser Cutters vs. Traditional Methods

When comparing production rates, metal laser cutters stand out against traditional methods. A report from the Laser Institute of America notes that laser cutting can achieve speeds up to 10 times faster than conventional saws. This efficiency means projects finish ahead of schedule. For businesses, this translates to reduced labor costs and increased throughput. One study indicated that companies adopting laser cutting saw productivity rise by 30%.

However, it’s crucial to recognize that not all projects benefit equally from high-speed cutting. For intricate designs or thick materials, laser cutters may struggle. Inefficiencies might also arise if staff are not adequately trained. Aligning your workforce with the technology is essential.

Tip: Regular maintenance can boost the speed of your laser cutter. This prevents downtime and keeps production flowing smoothly.

Conversely, while speed is essential, accuracy is equally important. Metal laser cutters provide precision that many traditional methods cannot match. A report from the Fabricators & Manufacturers Association states that laser cutting reduces material waste by up to 25%. This effectiveness enhances sustainability. Yet, achieving this level of precision requires attention to setup and calibration.

Tip: Always double-check settings before beginning a cut. Small adjustments can significantly impact outcomes.

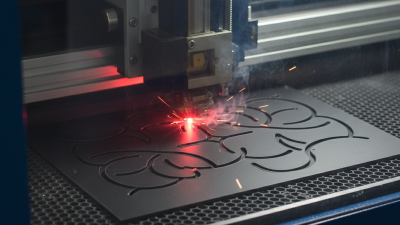

Versatility of Materials: Exploring the Range of Metals Cut by Laser Technology

Laser cutting technology offers a remarkable versatility when it comes to materials. Metal laser cutters can efficiently slice through a wide range of metals, including steel, aluminum, brass, and copper. According to a report by MarketsandMarkets, the metal cutting market is projected to reach $11.6 billion by 2025, driven by advancements in laser technologies. This growth highlights the increasing reliance on precise cutting techniques across various industries.

The adaptability of laser technology allows for intricate designs in thin and thick materials alike. For instance, sheet metal processing has gained traction in manufacturing sectors, where precision is crucial. Intricate patterns can be cut with minimal waste, but it's essential to consider the imperfections that can arise, such as dross or heat-affected zones on the edges. The thermal effects can impact material properties, emphasizing the need for skilled operators.

Moreover, different metals present unique challenges. Stainless steel may require specific settings to prevent burn-through. On the other hand, delicate metals necessitate careful adjustments to avoid excessive warping. These variances in material response demonstrate that while laser technology is advanced, it demands continuous learning and adaptation from users. Embracing this complexity can lead to innovative solutions, but it also highlights the importance of trial and error in mastering metal cutting techniques.

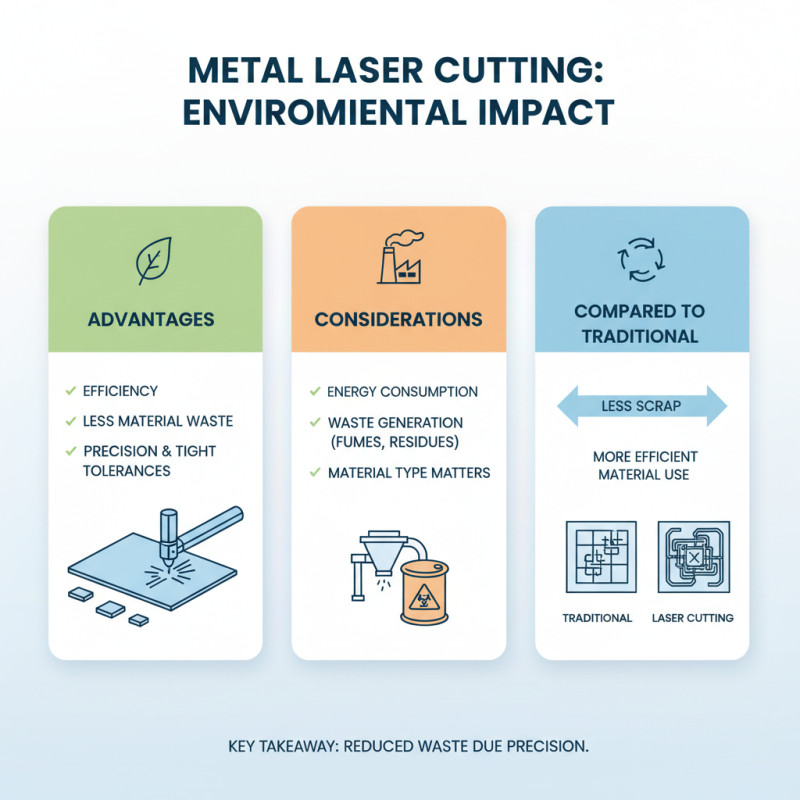

Environmental Impact: Assessing the Sustainability of Metal Laser Cutting Practices

Metal laser cutting offers numerous advantages, but its environmental impact deserves careful examination. While this technology is efficient, it can also generate waste. However, laser cutting tends to produce less scrap compared to traditional methods. This is largely because of its precision, allowing for tighter tolerances and cleaner cuts.

Using metal laser cutters can lead to sustainable practices. For instance, many operations now focus on recycling scrap metal. The energy consumption of laser cutting is often more efficient than that of other methods. This efficiency reflects a growing trend toward sustainability in manufacturing.

Tips: Choose materials wisely. Prioritize recycled metals when possible. Aim to minimize waste during the design phase. Also, regularly maintain your laser cutter. This helps ensure it operates at peak efficiency. Reflecting on these practices can lead to more sustainable project outcomes.