Minimal Space. Maximum Impact! Designed for when every millimeter matters> the new IRONLESS UNANO SERIES

- Company

-

Applications

Semiconductors

Increase throughput and precision of your system

Display

Enhance accuracy and precision with linear motors

Science and aerospace

Improve motion quality for a variety of applications

Machine tooling

Robust solutions for increased speed and precision

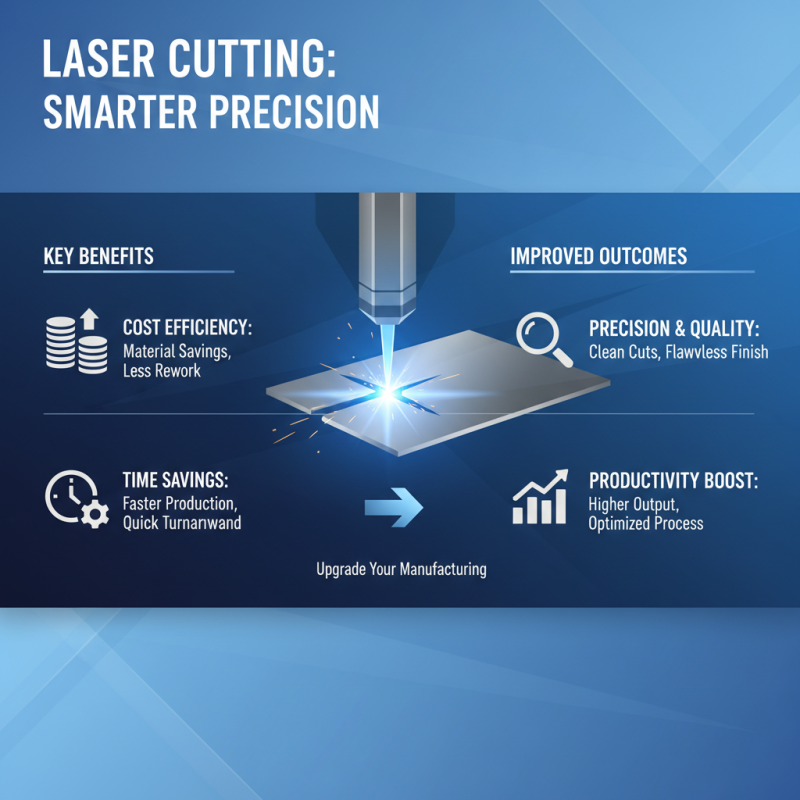

Digital cutting

Create modular and high throughput applications

Printing

Increase printing speed and quality using linear motors

Robotics

Integrate compact solutions for guaranteed uptime and high dynamics

Life science

Establish precise and clean integrated solutions

Woodworking

Maximize performance and accuracy for high throughput

Stages and system solutions

Compact integration and high performance for your axis

Vacuum applications

Best performance for clean and vacuum applications

-

Products

Characteristics

- Resources