Understanding the Benefits of High Torque Motors in Modern Engineering Applications

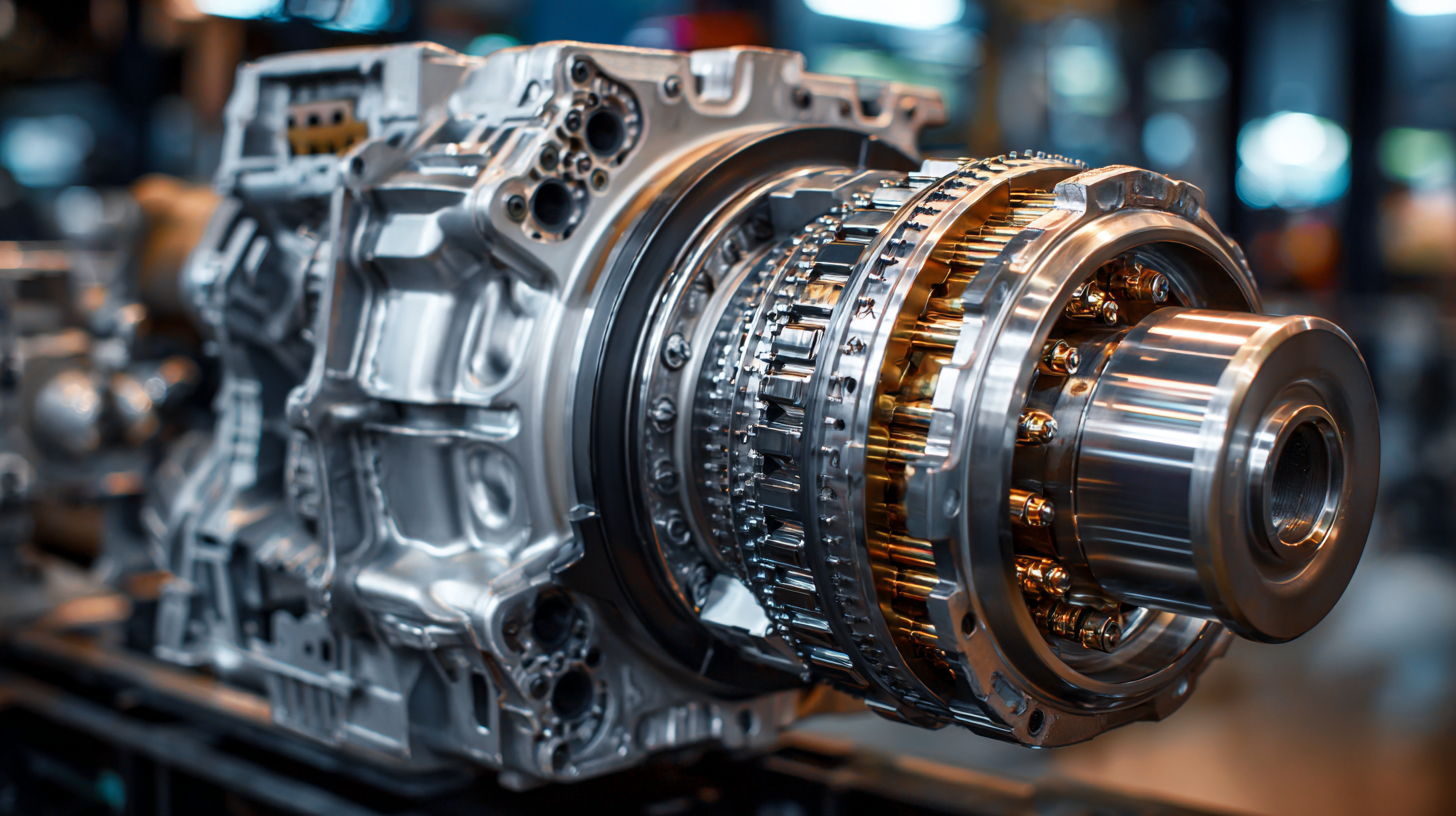

In recent years, the integration of high torque motors in modern engineering applications has revolutionized various industries, enhancing efficiency and performance. A high torque motor is designed to deliver substantial rotational force at low speeds, making it ideal for demanding tasks in areas such as automotive, robotics, and manufacturing.

These motors play a critical role in powering heavy machinery, enabling precise control over complex operations and improving the overall productivity of engineering processes. As such, understanding the benefits of high torque motors becomes essential for engineers and designers aiming to optimize their systems.

By leveraging the unique characteristics of these motors, such as their ability to handle significant loads while maintaining operational stability, professionals can innovate solutions that meet the ever-evolving demands of the engineering landscape, ultimately driving advancements and fostering sustainability across various sectors.

These motors play a critical role in powering heavy machinery, enabling precise control over complex operations and improving the overall productivity of engineering processes. As such, understanding the benefits of high torque motors becomes essential for engineers and designers aiming to optimize their systems.

By leveraging the unique characteristics of these motors, such as their ability to handle significant loads while maintaining operational stability, professionals can innovate solutions that meet the ever-evolving demands of the engineering landscape, ultimately driving advancements and fostering sustainability across various sectors.

Key Advantages of High Torque Motors in Engineering Design

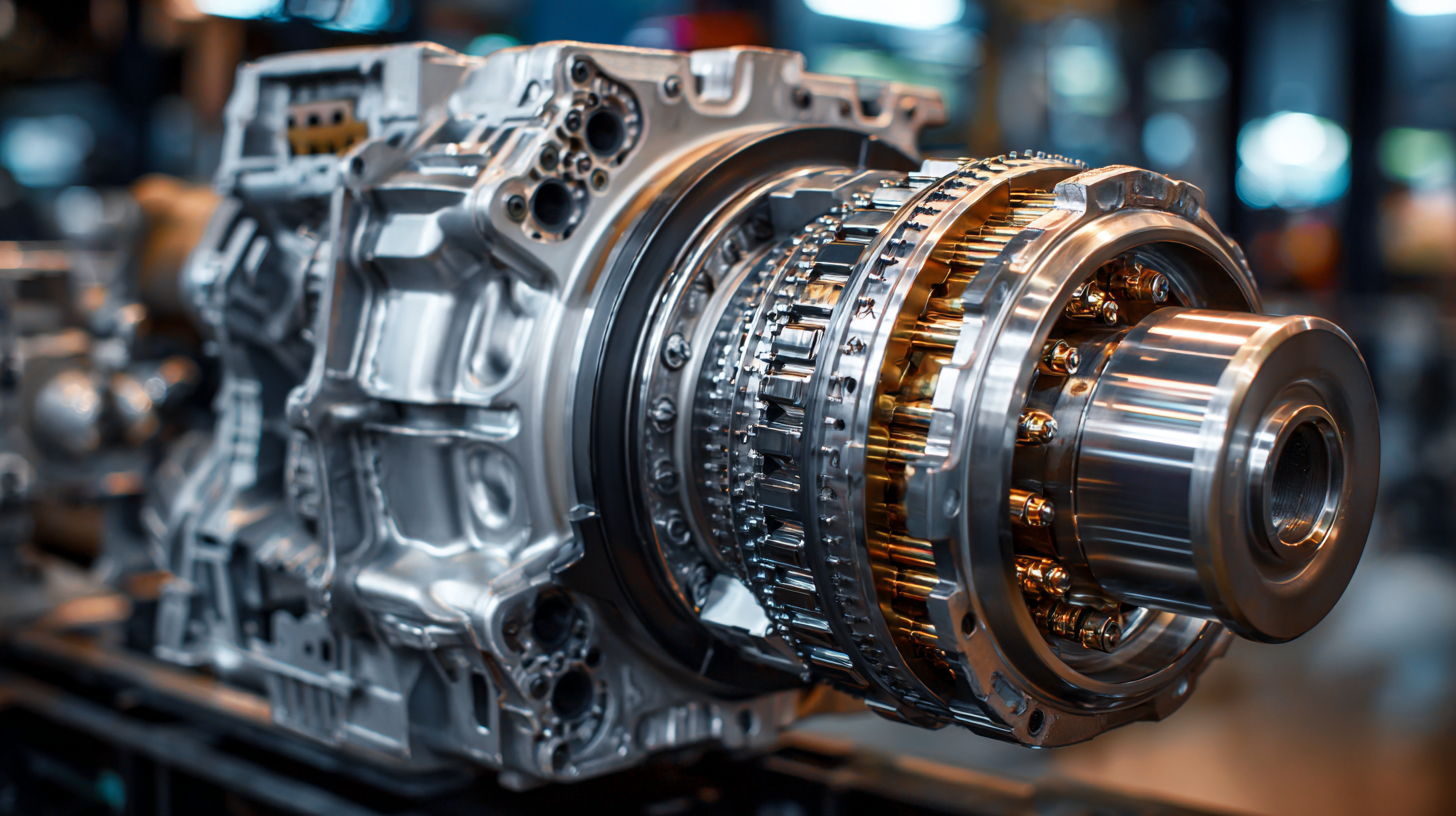

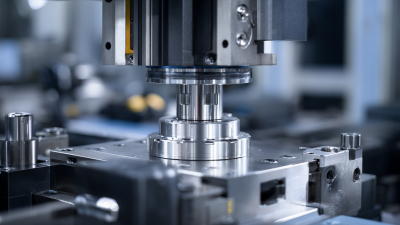

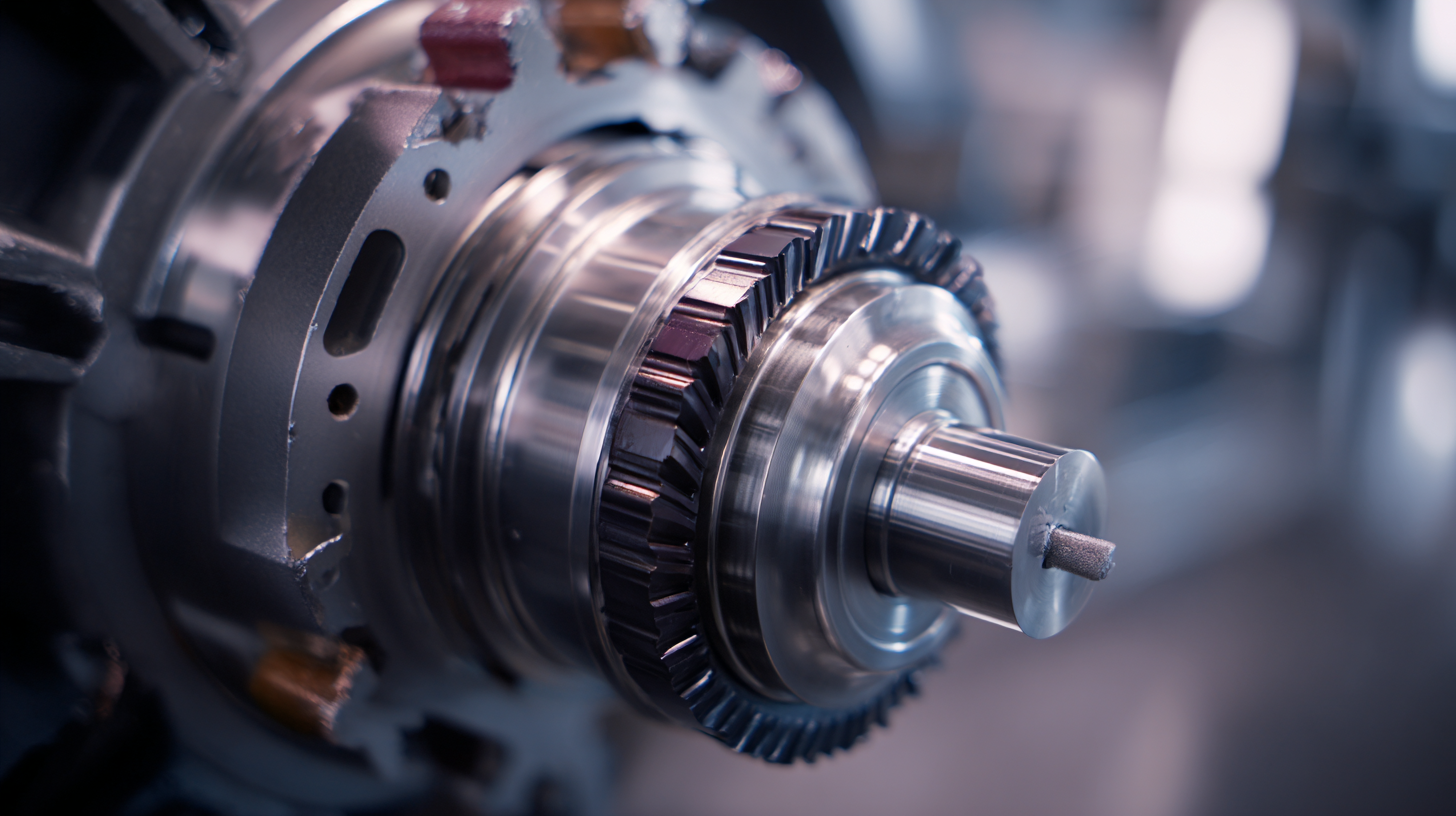

High torque motors have become indispensable in modern engineering applications due to their exceptional ability to deliver high power at low speeds. This characteristic is particularly advantageous in scenarios such as conveyor systems, robotic automation, and heavy machinery, where heavy loads need to be moved efficiently. The enhanced torque allows systems to start from zero load and accelerate smoothly, minimizing mechanical stress and prolonging the lifespan of components.

Another key advantage of high torque motors is their efficiency in energy consumption. As they provide greater power without needing to increase speed, they can operate at lower energy costs compared to traditional motors. This efficiency is crucial in applications where energy conservation is a priority, aligning with global efforts to reduce carbon footprints and optimize resource use.

Furthermore, the compact size of high torque motors enables more flexible engineering designs, making it easier to integrate them into existing systems or to create new, innovative solutions in various fields, from automotive to manufacturing.

How High Torque Motors Improve Efficiency in Industrial Applications

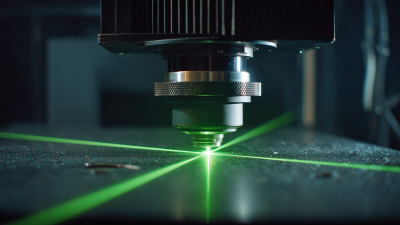

High torque motors play a crucial role in enhancing efficiency across various industrial applications. The increasing adoption of brushless DC motors highlights the significant advantages these motors provide, including superior efficiency and performance. By utilizing advanced algorithms to predict torque and speed, industries can optimize their systems, leading to better energy consumption and operational output. This innovation is essential as companies strive to meet sustainability goals and reduce carbon emissions.

Moreover, the growing market for high-torque synchronous motors and stepper motors illustrates a notable trend within modern engineering. The European market, for instance, is projected to witness substantial growth in revenue, underscoring the demand for efficient power solutions. Additionally, innovations like the Thunder range of high-torque direct drives further emphasize the ongoing evolution of motor technologies, pushing the boundaries of what is possible in industrial machinery. As industries continue to prioritize efficiency, the role of high torque motors will undoubtedly become more prominent in shaping future applications.

Selecting the Right High Torque Motor for Your Project Needs

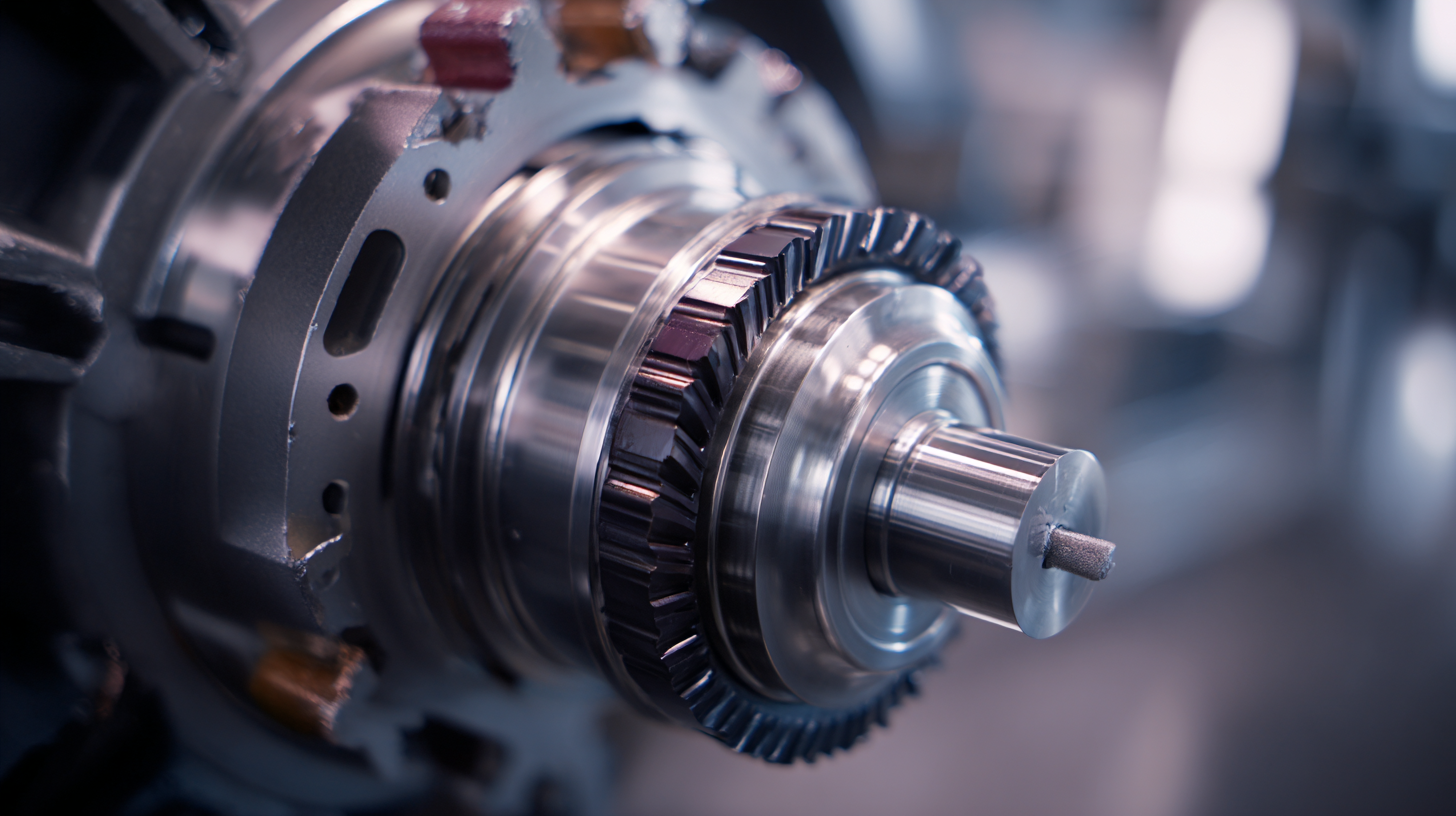

When selecting the right high torque motor for your project needs, it's essential to consider several key factors that influence performance and efficiency. First, analyze the specific requirements of your application, such as load capacity, speed, and operating environment. Different motors are designed for various conditions; for instance, a DC motor might be more suitable for applications requiring precise speed control, while an AC motor may be better for continuous operations where high torque at lower speeds is crucial.

Additionally, evaluating the physical dimensions and weight of the motor is vital. Compact spaces may necessitate a more compact motor, whereas larger setups might accommodate bulkier options. Compatibility with existing systems, including power supply and control systems, should also be assessed. Choose a motor that not only meets the torque and operational demands but also integrates seamlessly into your project. By carefully considering these aspects, you can identify the most effective high torque motor that aligns with your engineering goals, ensuring optimal performance and longevity.

Integrating High Torque Motors into Automated Systems Effectively

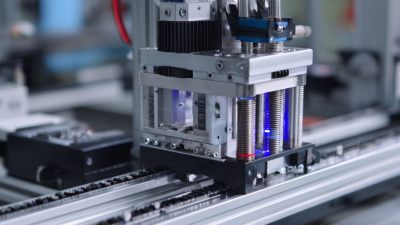

High torque motors are increasingly being integrated into automated systems across various industries due to their ability to handle heavy loads and provide precise control. When effectively incorporated, these motors enhance the performance and efficiency of machinery, leading to significant advancements in automation technology. Understanding how to integrate them requires careful consideration of the system’s requirements, such as load capacity, speed, and control mechanisms.

Tip: Always analyze the torque requirements of your application before selecting a motor. This will help in avoiding underperformance or overloading, ensuring your automated system runs smoothly without unexpected downtimes.

Incorporating high torque motors isn't just about the hardware; it also involves optimizing software control systems. The right software can facilitate real-time monitoring and adjustments, improving the overall responsiveness of the automated system. Using advanced algorithms can help in fine-tuning motor outputs according to varying operational demands.

Tip: Regularly update and calibrate your control software to accommodate changes in load patterns or operational conditions. This practice maintains the reliability and efficiency of high torque motors integrated into your systems.

Understanding the Benefits of High Torque Motors in Modern Engineering Applications

Future Trends and Innovations in High Torque Motor Technology

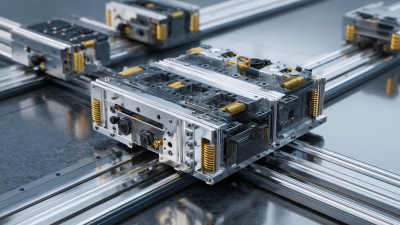

High torque motors are increasingly gaining attention in modern engineering, particularly due to their capability to deliver significant torque at low speeds. As industries evolve, the demand for more efficient and powerful motors leads to innovative designs and technologies. Future trends in high torque motor technology are expected to focus on enhanced energy efficiency through the use of advanced materials and improved thermal management systems. This will not only reduce energy consumption but also extend the lifespan of the motors, ultimately benefiting manufacturers and end-users alike.

Moreover, the integration of smart technologies and digitalization is set to revolutionize high torque motor applications. Innovations such as IoT connectivity and machine learning algorithms will enable real-time monitoring and predictive maintenance, minimizing downtime and maintenance costs. Additionally, advancements in motor control systems will facilitate precise positioning and speed control, making high torque motors invaluable in automation, robotics, and electric vehicles. As the demand for sustainable and efficient engineering solutions grows, high torque motors are poised to become a cornerstone of future industrial advancements.

These motors play a critical role in powering

These motors play a critical role in powering